A method for detecting elemental sulfur

A technology of elemental sulfur and detection liquid, which is applied in the direction of color/spectral characteristic measurement, material analysis by observing the influence on chemical indicators, and analysis by making materials undergo chemical reactions, etc. It can solve complex operations, long detection cycles, High detection limit and other problems, to achieve the effect of simple preparation process, quantitative detection, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Preparation of detection solution: Take 300ul of hydrazine hydrate solution (mass concentration: 98%) and add it to 3ml of N,N-dimethylformamide (DMF) solution and magnetically stir at a speed of 500r / min for 10min to prepare the detection solution. The volume ratio of N,N-dimethylformamide and hydrazine hydrate solution is 1:10;

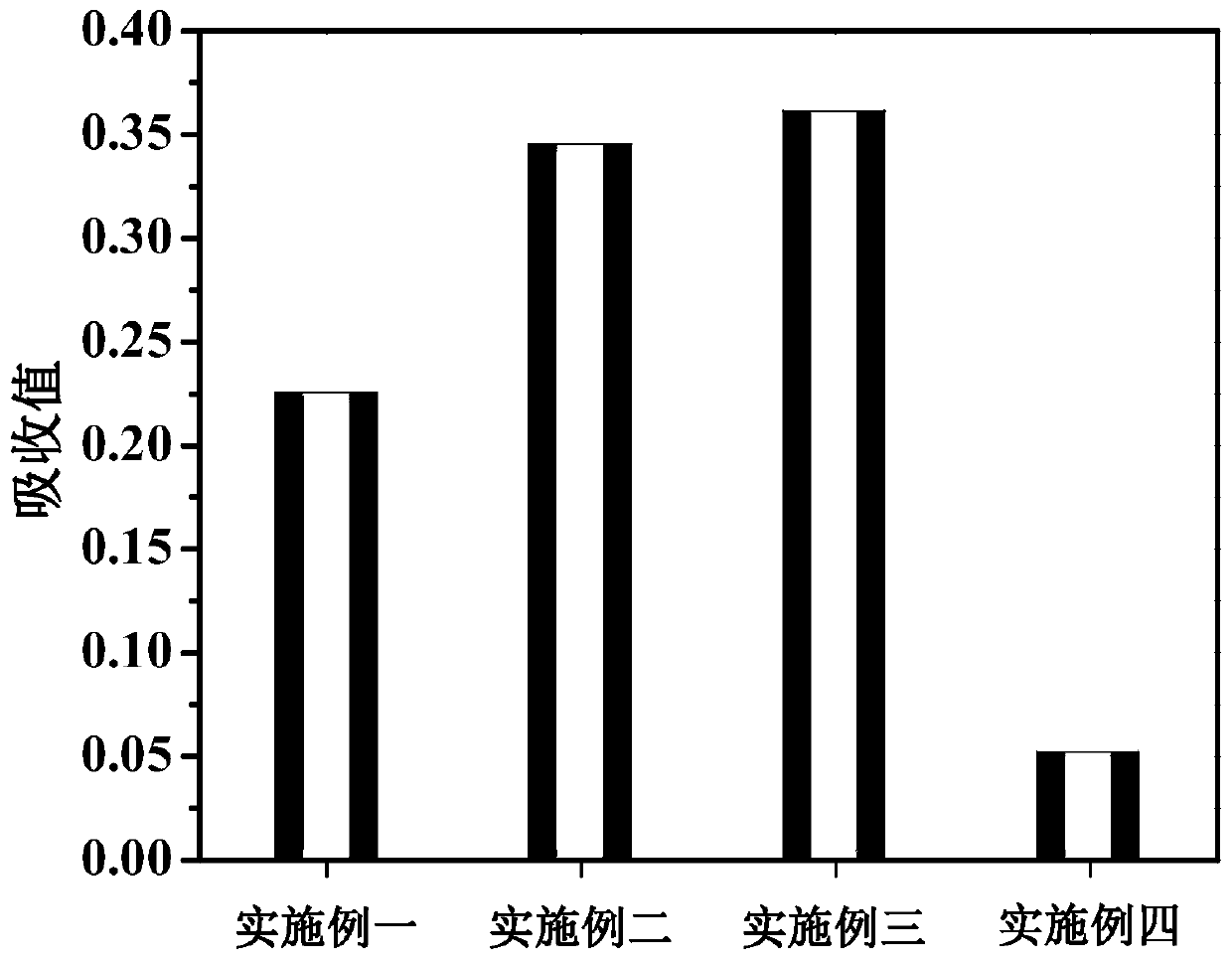

[0038] 2) Add the ethanol solution of 300ul sulfur to the detection solution obtained in step 1) to obtain a mixed solution (the concentration of the ethanol solution of sulfur is 100mg / L, that is, the quality of sulfur in 1L ethanol solution is 100mg), after the mixed solution is blue Immediately (within 30s) carry out ultraviolet-visible light detection on the mixed solution, figure 2 The absorption value at 617nm wavelength after color development is given in .

Embodiment 2

[0040]1) Preparation of detection solution: Take 100ul of hydrazine hydrate solution (98% in mass concentration) and add it to 3ml of N,N-dimethylformamide (DMF) solution and magnetically stir at a speed of 500r / min for 10min to prepare the detection solution. The volume ratio of N,N-dimethylformamide and hydrazine hydrate solution is 1:30;

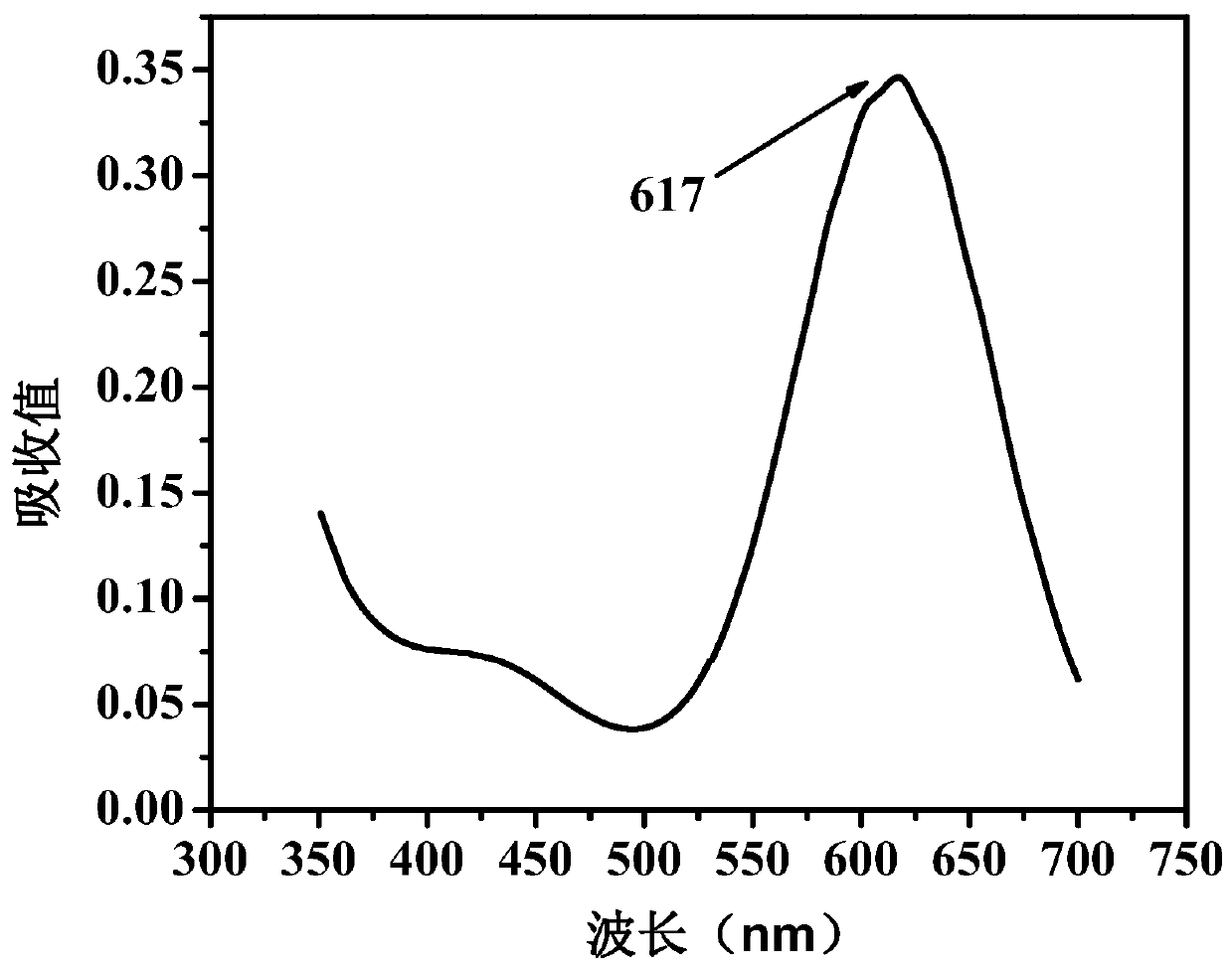

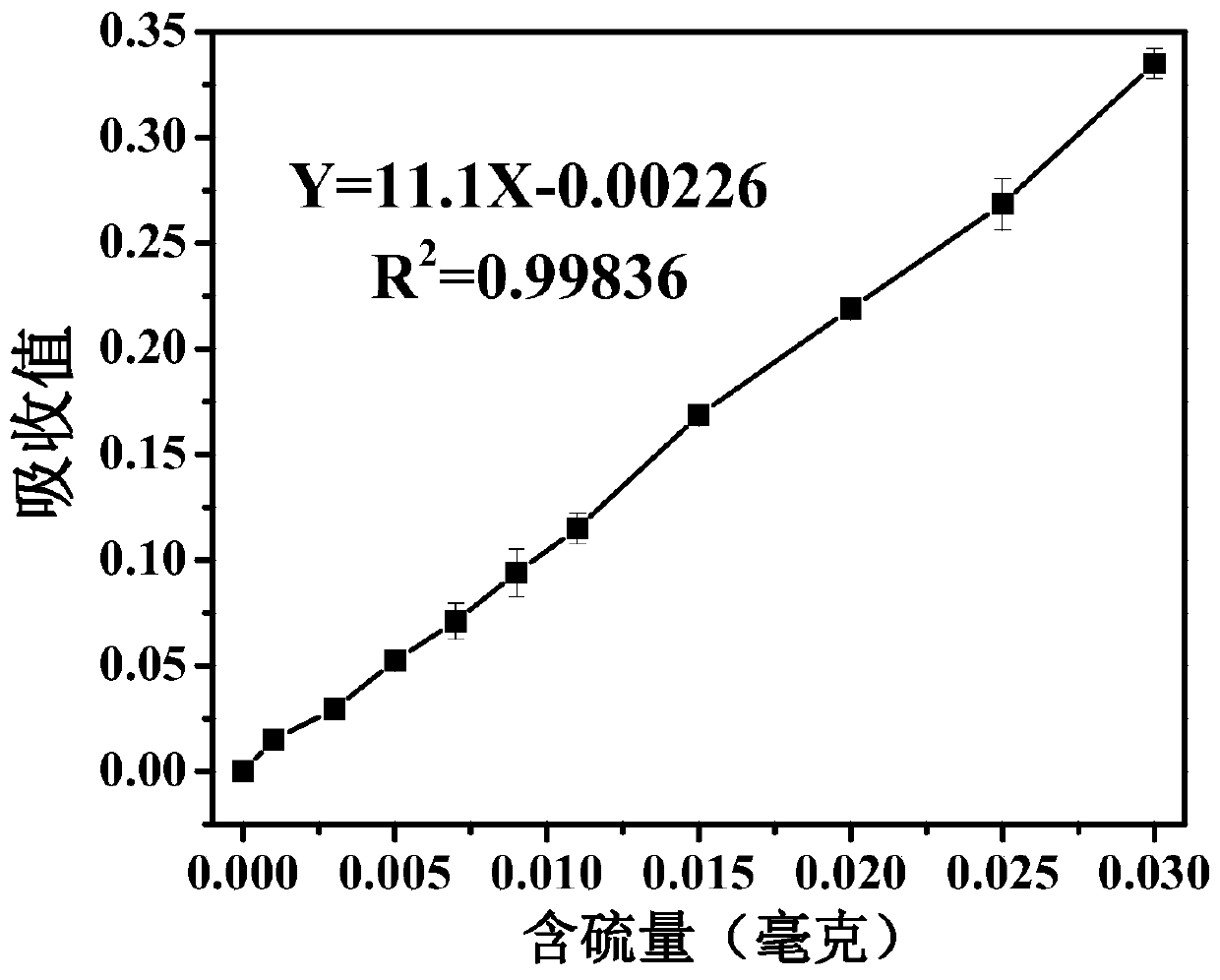

[0041] 2) Add 300ul sulfur ethanol solution to the detection solution obtained in step 1) to obtain a mixed solution (the concentration of sulfur ethanol solution is 100mg / L), and immediately (within 30s) the solution is detected by ultraviolet-visible light after the mixed solution turns blue , the result is as figure 1 shown by figure 1 It can be seen that the sample has an absorption peak at a wavelength of 617nm after developing color in the detection solution; this also echoes the blue color of the solution;

[0042] 3) Add 300ul of sulfur ethanol solution (concentration is 100mg / L) to the detection solution obtained in step 1), af...

Embodiment 3

[0048] 1) Preparation of detection solution: Take 60ul of hydrazine hydrate solution (98% mass concentration) and add it to 3ml of N,N-dimethylformamide (DMF) solution and magnetically stir at a speed of 500r / min for 10min to prepare the detection solution. The volume ratio of N,N-dimethylformamide and hydrazine hydrate solution is 1:50;

[0049] 2) Add 300ul of sulfur ethanol solution (concentration is 100mg / L) to the detection solution obtained in step 1), after the solution is blue, the solution is immediately detected by ultraviolet-visible light, figure 2 The absorption value at 617nm wavelength after color development is given in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com