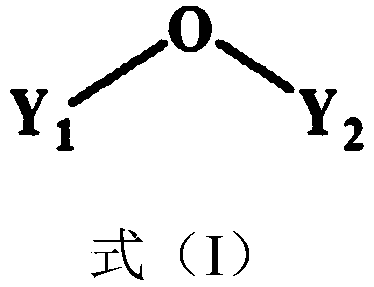

A non-aqueous electrolyte for a lithium ion battery and a lithium ion battery using the electrolyte

A lithium-ion battery, non-aqueous electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of high flash point, high oxidation decomposition voltage, poor solubility, etc., to improve oxidation voltage, enhance stability, and improve the ability to work stably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

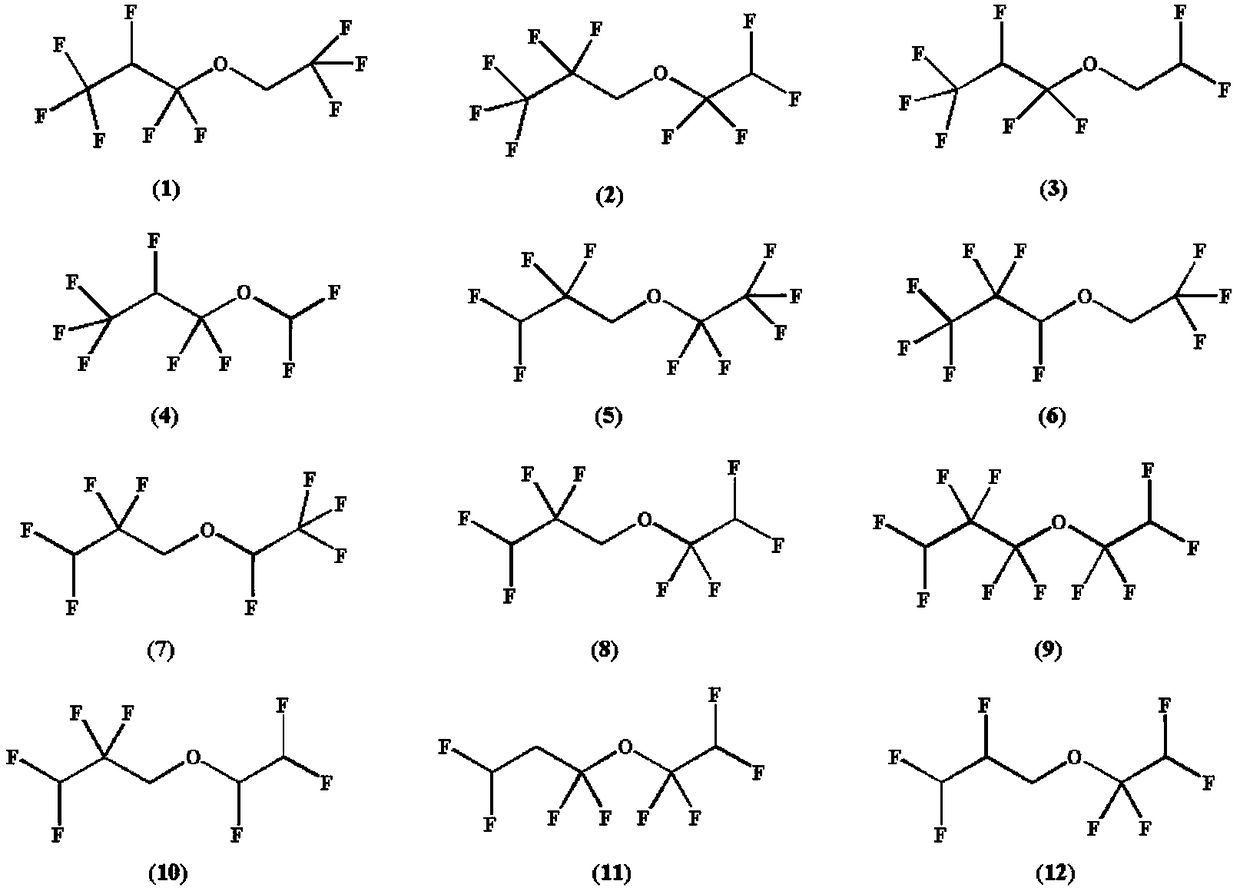

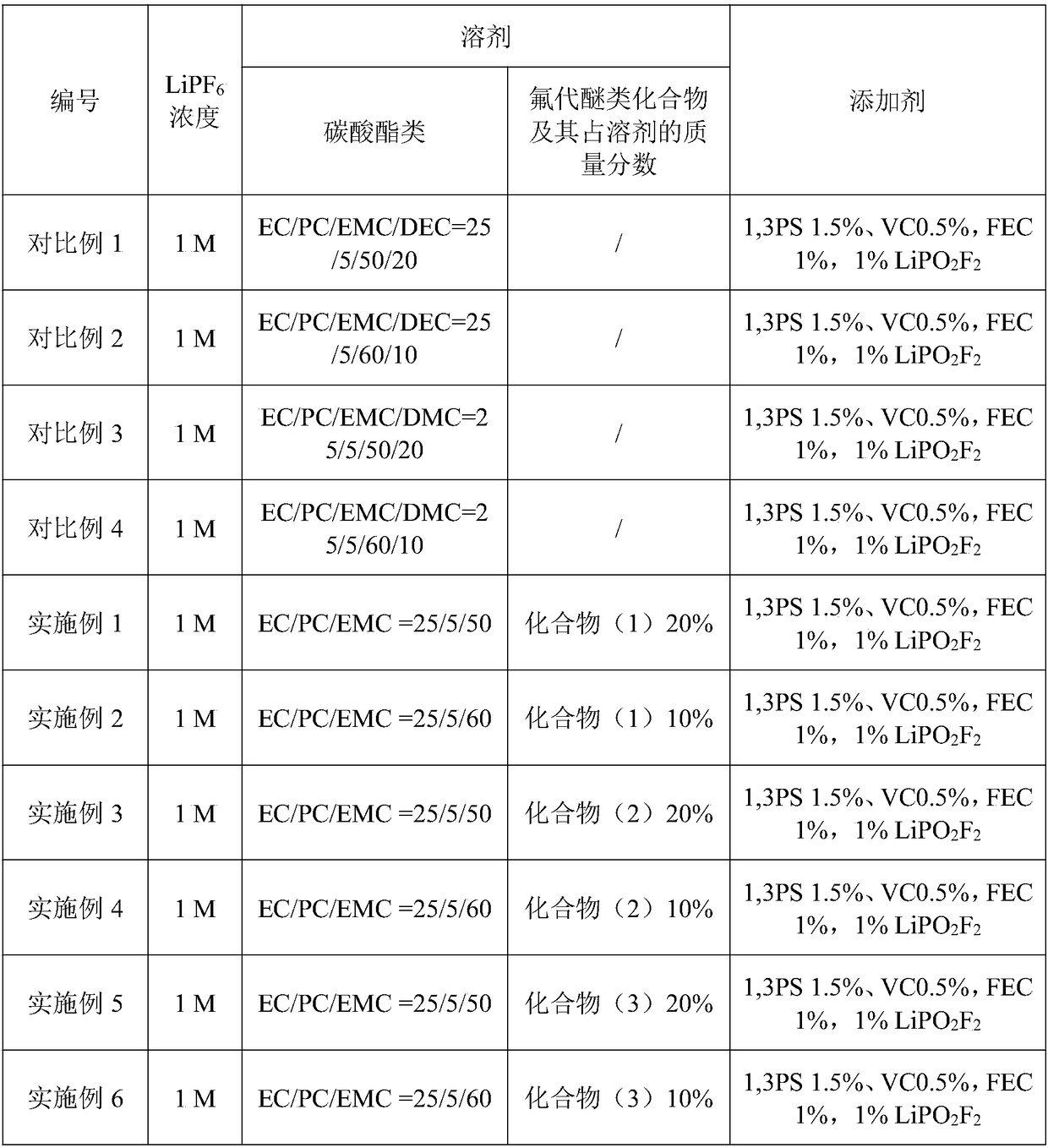

[0028] Described nonaqueous electrolytic solution is prepared as follows: in glove box, ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and compound (1) are according to weight ratio 25:5: Mixed at a ratio of 50:20, and then added lithium hexafluorophosphate for dissolution to prepare an electrolyte solution with a lithium hexafluorophosphate concentration of 1M. After that, 0.5% of vinylene carbonate, 1% of fluoroethylene carbonate (FEC), 1.5% of 1,3 propane sultone and 1% of lithium difluorophosphate ( LiPO 2 f 2 ).

[0029] Inject the prepared non-aqueous electrolyte for lithium-ion batteries into fully dried 4.35V NCM (nickel: cobalt: manganese = 5:2:3) / graphite soft-pack batteries, and put them on hold at 45°C, high-temperature fixture formation and After the secondary sealing and other procedures, the battery performance test was carried out to obtain the battery used in Example 1.

Embodiment 2

[0031]The positive electrode and negative electrode preparation method of embodiment 2 are the same as embodiment 1; The difference is that ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and compound (1) in embodiment 2 Configure according to the ratio of weight ratio 25:5:60:10.

Embodiment 3

[0033] The positive electrode and negative electrode preparation method of embodiment 3 are the same as embodiment 1; The difference is that ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and compound (2) in embodiment 3 Mix in a ratio of 25:5:50:20 by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com