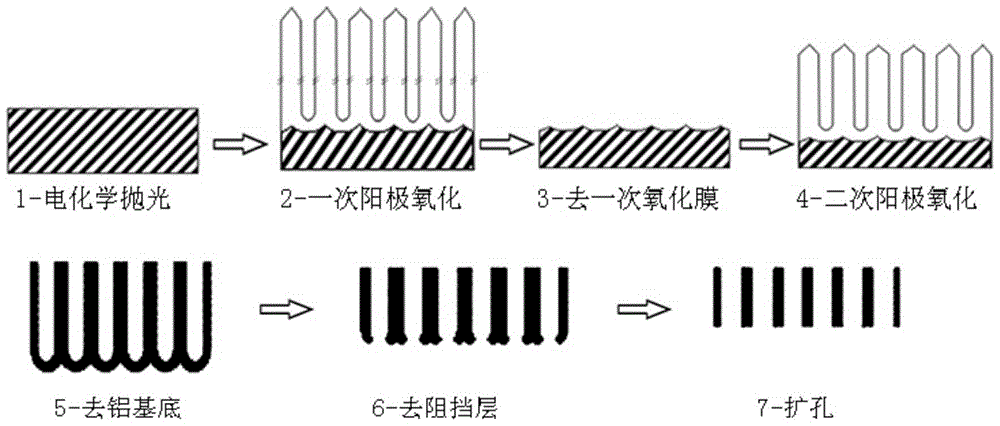

Preparation method of double-sided uniform porous anodized aluminum nano-template

An aluminum oxide nanometer and porous anode technology, applied in the field of materials, can solve the problems of reducing pore density, slow reaction speed, small pore spacing, etc., and achieve the effect of increasing the reaction speed, shortening the process cycle, and the method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

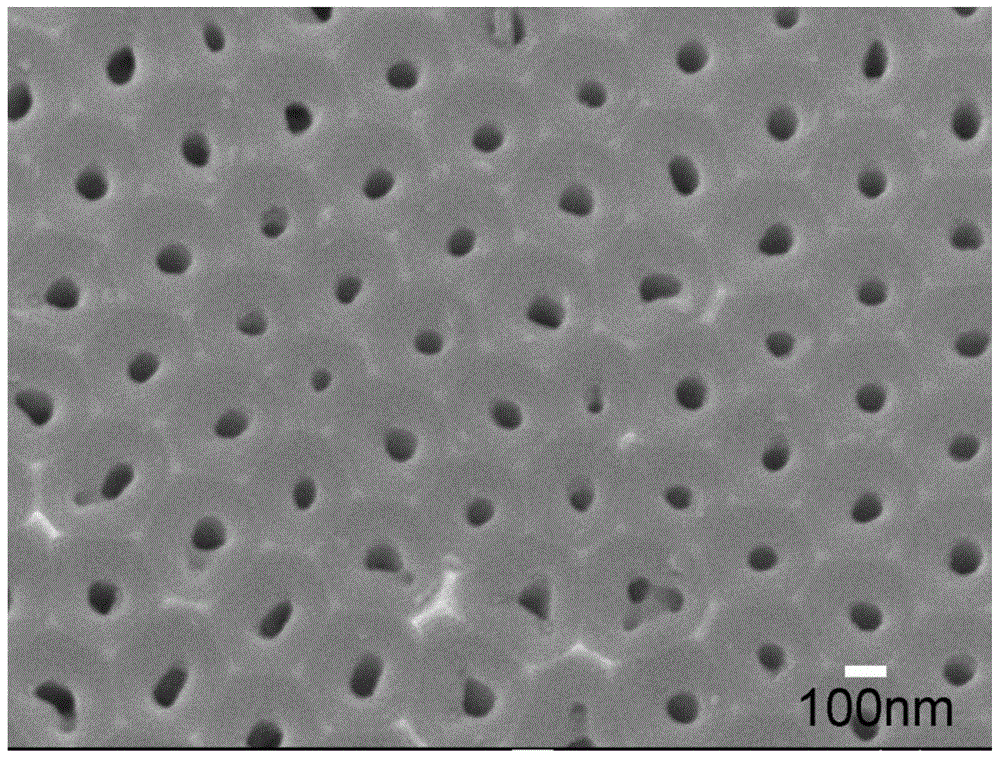

Embodiment 1

[0029] Step 1. Firstly, the aluminum sheet with a purity of 99.99% is cut into a square with a side length of 30 cm, and undergoes traditional high-temperature annealing treatment and cleaning pretreatment. The pretreated high-purity aluminum sheet is used as the anode, and the graphite is used as the cathode. In a mixed solution of perchloric acid and ethanol with a volume ratio of 1:4, the set voltage is 20V, and the electrolysis reaction takes 2 minutes to polish the front of the aluminum sheet. .

[0030]Step 2: The polished aluminum sheet is used as an anode, and the graphite is used as a cathode, and the first electrochemical anodic hard oxidation reaction is performed. Use 0.3mol / L oxalic acid solution as the electrolyte, set the reaction temperature at 1°C, first apply 40V voltage for 5min, then adjust the voltage to 120V at a speed of (0.5-1)V / s, and then react for 30min.

[0031] Step three, using 0.2mol / L of CrO 3 and 0.4mol / L of H 3 PO 4 The acidic mixed soluti...

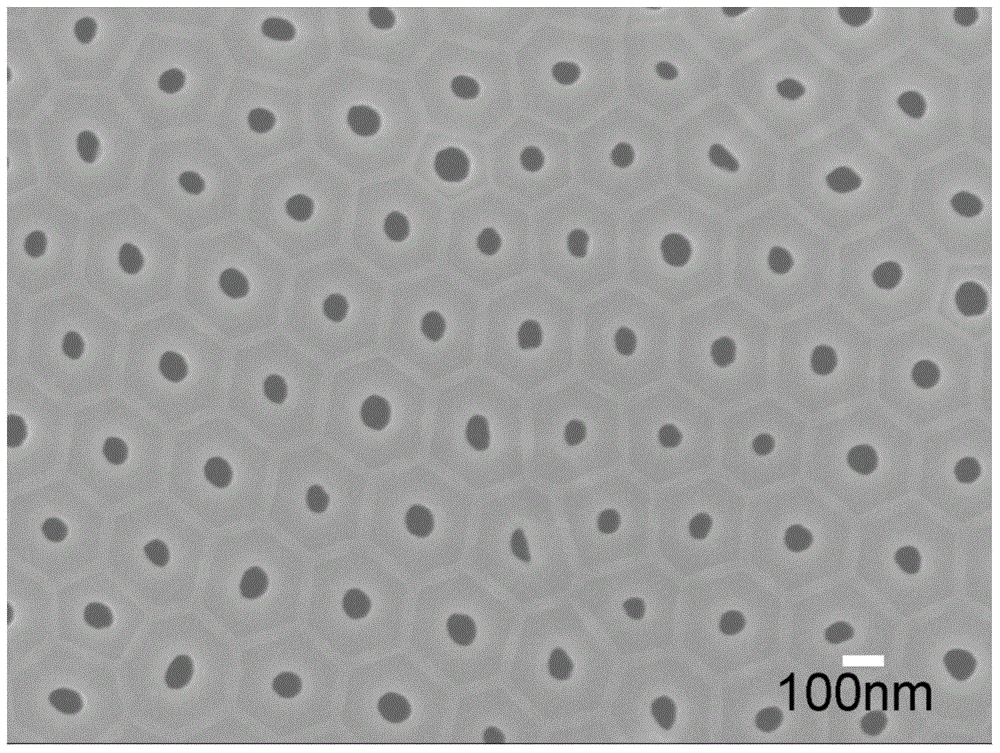

Embodiment 2

[0036] Step 1. Firstly, the aluminum sheet with a purity of 99.99% is cut into a square with a side length of 30 cm, and undergoes traditional high-temperature annealing treatment and cleaning pretreatment. The treated high-purity aluminum sheet was used as the anode, and the graphite was used as the cathode. In a mixed solution of perchloric acid and ethanol with a volume ratio of 1:4, the voltage was set at 25V, and the electrolytic reaction was performed for 2 minutes. The front side of the aluminum sheet was polished.

[0037] Step 2: The polished aluminum sheet is used as an anode, and the graphite is used as a cathode, and the first electrochemical anodic hard oxidation reaction is performed. Use 0.3mol / L oxalic acid solution as the electrolyte, set the reaction temperature at 1°C, first apply 40V voltage for 5min, then adjust the voltage to 110V at a speed of (0.5-1)V / s, and then react for 30min.

[0038] Step three, using 0.2mol / L of CrO 3 and 0.4mol / L of H 3 PO 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com