Electrolyte and method for preparing aluminum oxide template with big hole pitch

An alumina template, pore spacing technology, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of volatile organic solvents, harsh experimental conditions, low reaction temperature, etc., to improve corrosion resistance and Abrasion resistance, difficulty reduction, high oxidation voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

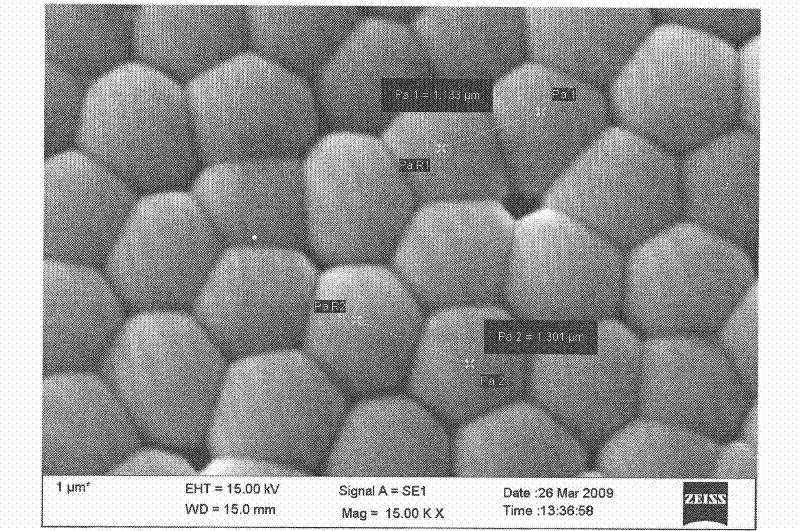

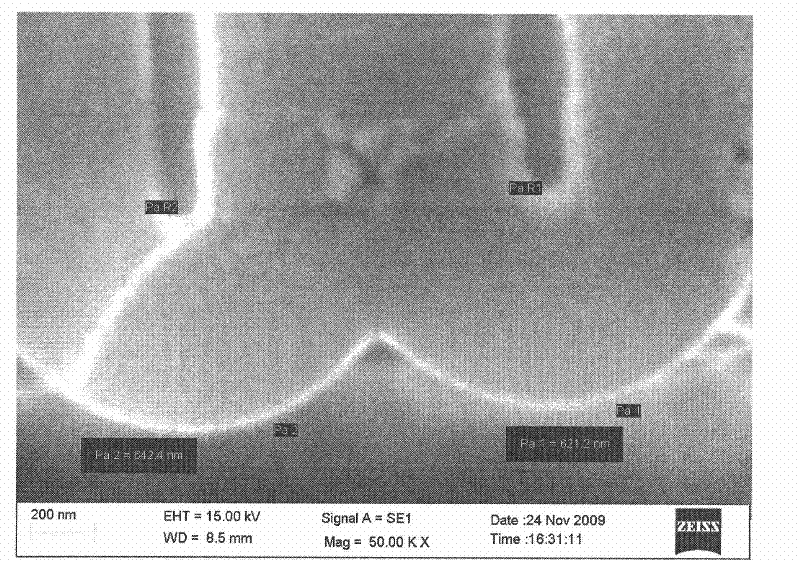

Image

Examples

Embodiment 1

[0028] Example 1, the electrolyte solution used to prepare the alumina template with large pore spacing is composed of: 0.05% to 2% oxalic acid, 0.05% to 1% sodium tungstate, 0.05% to 1.5% phosphoric acid di Ammonium hydrogen or boric acid or ammonium adipate, the balance of deionized water.

Embodiment 2

[0029] Example 2, the electrolyte solution used to prepare the alumina template with large pore spacing is composed of: 0.05% oxalic acid, 0.05% sodium tungstate, 0.05% ammonium dihydrogen phosphate or boric acid or ammonium adipate , the balance of deionized water.

Embodiment 3

[0030] Example 3, the electrolyte solution used to prepare the alumina template with large pore spacing is composed of: 2% oxalic acid, 1% sodium tungstate, 1.5% ammonium dihydrogen phosphate or boric acid or ammonium adipate , the balance of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com