High barrier water-based adhesive

An adhesive and barrier technology, used in water-based adhesives, composite films, and high-barrier water-based adhesives, and in the field of preparing the composite films, it can solve problems such as environmental damage, lack of bonding function, and volatile organic compound emissions. Effects of bond strength, excellent oxygen barrier properties, good processability and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

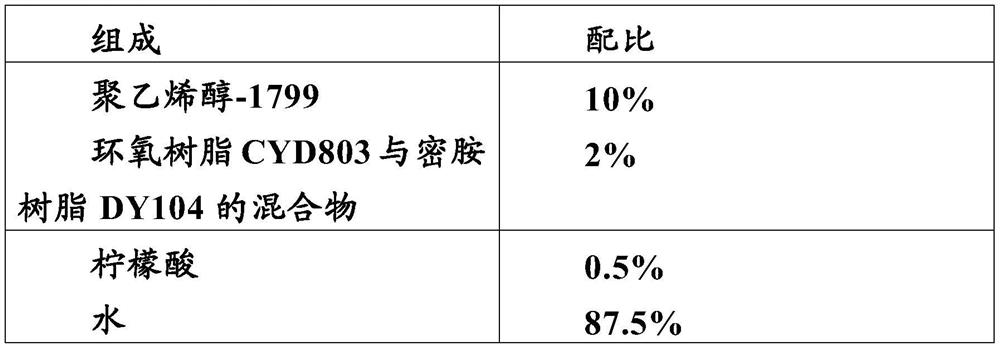

[0190] According to the following ratio, add polyvinyl alcohol-1799 and water into a heatable reaction vessel, and heat to 80°C-90°C under stirring to dissolve completely. After the temperature drops to 35°C-10°C, add a mixture of epoxy resin and melamine resin (0.3:1 weight ratio), stir and mix thoroughly, heat to 40°C-45°C and keep it warm for 8 hours, then drop to room temperature (25°C-15°C), the high-barrier water-based adhesive main agent is obtained after filtration, the main agent does not produce gel phenomenon when stored at 10°C-40°C for 70 days, and has good storage stability. Add citric acid and stir thoroughly before use to obtain a high-barrier water-based adhesive.

[0191]

[0192] Use the prepared high-barrier water-based adhesive to compound BOPP film and PE film. The process is as follows: On the dry laminating machine, the BOPP film with a thickness of 20 μm is placed on the main unwinder, and the high-barrier water-based adhesive is coated on the BOPP ...

Embodiment 2

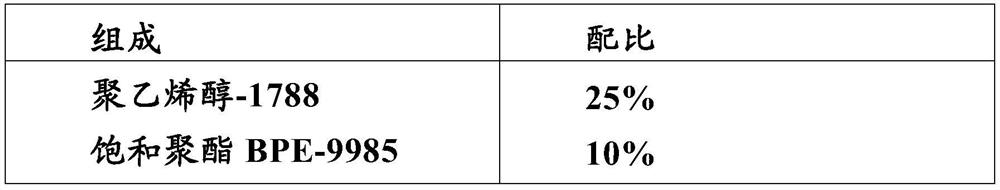

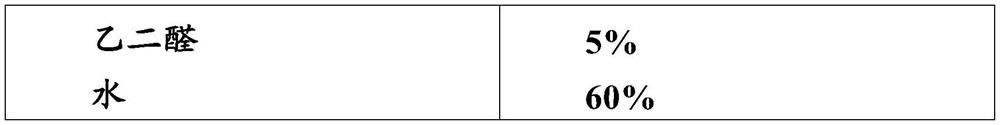

[0195] According to the following ratio, add polyvinyl alcohol-1788 and water into a heatable reaction vessel, and heat to 60°C-70°C under stirring to dissolve completely. After the temperature drops to 20°C-10°C, add saturated polyester, stir and mix thoroughly, heat to 50°C-70°C, keep warm for 12 hours, then drop to normal temperature (15°C-10°C), filter to obtain high barrier Water-based adhesive main agent, the main agent does not produce gel phenomenon when stored at 10°C-40°C for 70 days, and has good storage stability. Add glyoxal and stir thoroughly before use to obtain a high-barrier water-based adhesive.

[0196]

[0197]

[0198]Use the prepared high-barrier water-based adhesive to compound BOPA film and PE film. The process is as follows: On the dry laminating machine, place a BOPA film with a thickness of 15 μm on the main unwinder, and apply the high-barrier water-based adhesive on the BOPA film. The amount of glue is 8 grams per flat. Dry the glue after ...

Embodiment 3

[0201] Add the mixture of polyvinyl alcohol and polyvinylpyrrolidone (1:0.5 weight ratio) and water into a heatable reaction vessel according to the following ratio, and heat to 80°C-90°C under stirring to dissolve completely. After the temperature drops to 30°C-20°C, add polyurethane, stir and mix thoroughly, heat to 45°C and keep it warm for 7 hours, then drop to normal temperature (29°C-20°C), and filter to obtain the main agent of water-based adhesive. It does not produce gel phenomenon when stored at 10°C-30°C for 30 days, and has good storage stability. Add the oxazoline polymer and stir thoroughly before use to obtain the water-based adhesive.

[0202]

[0203] Use the prepared high-barrier water-based adhesive to compound BOPP film and CPP film. The process is as follows: On the dry laminating machine, the BOPP film with a thickness of 15 μm is placed on the main unwinder, and the high-barrier water-based adhesive is coated on the BOPP film. The amount of glue is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com