Maillard reaction product as well as preparation method and application thereof

A technology of Maillard reaction and products, which is applied in the field of Maillard reaction products and their preparation, to achieve the effects of strong operability, improved oral aftertaste, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

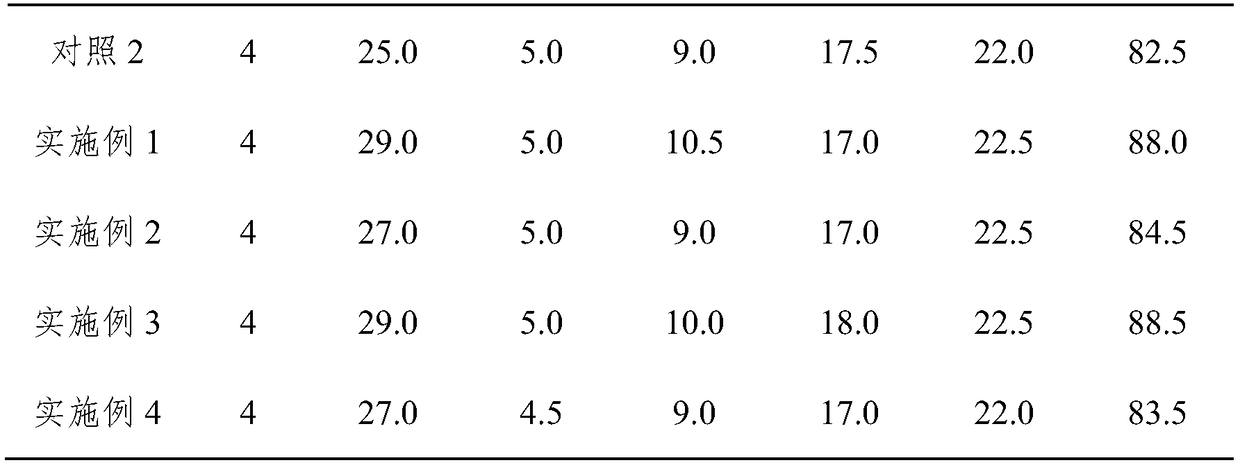

Examples

Embodiment 1

[0034] The present embodiment provides a kind of Maillard product and preparation method thereof, specifically as follows:

[0035] After dissolving 20g of sodium citrate in 200mL of water, add 300g of asparagine, 150g of aspartic acid, 150g of proline, 50g of glutamic acid, 50g of alanine, 20g of serine, 20g of phenylalanine, threonine After stirring 10 g of acid and 5 g of leucine until they are completely dissolved, add 810 g of fructose and 225 g of xylose in turn, stir until they are completely dissolved, then add 200 mL of glycerol, and adjust the pH to 7 with sodium hydroxide. Transfer the above materials to a reaction kettle, tighten the metal cover and place it in an oven, heat it at 135°C for 2 hours, cool it down to room temperature with cold water after the reaction is completed, filter, discard the insoluble matter, and take the upper layer to obtain Reaction products Maillard reaction products.

Embodiment 2

[0039] The present embodiment provides a kind of Maillard product and preparation method thereof, specifically as follows:

[0040]After dissolving 30g of sodium citrate in 300mL of water, add 300g of asparagine, 300g of aspartic acid, 200g of proline, 200g of glutamic acid, 100g of alanine, 50g of phenylalanine, 50g of histidine and Glycine 25g, stir until completely dissolved, add 1215g fructose, 338g xylose in turn, stir until completely dissolved, add 300mL glycerin, adjust pH to 8 with sodium hydroxide. Transfer the above materials to the reaction kettle, tighten the metal cover and place it in an oven, heat at 140°C for 1.5h, cool to room temperature with cold water after the reaction is completed, filter, discard the insoluble matter, and take the upper layer to prepare The reaction product Maillard reaction product was obtained.

Embodiment 3

[0044] The present embodiment provides a kind of Maillard product and preparation method thereof, specifically as follows:

[0045] After dissolving 20g of sodium citrate in 200mL of water, add 200g of asparagine, 200g of aspartic acid, 150g of proline, 100g of glutamic acid, 100g of alanine, 30g of serine, 30g of phenylalanine, histamine Add 30g of acid, 15g of threonine, 15g of glycine and 15g of leucine, stir until completely dissolved, then add 975g of fructose, 270g of xylose, stir until completely dissolved, then add 200mL of glycerin, adjust the pH to 6 with citric acid. Transfer the above materials to the reaction kettle, tighten the metal cover and place it in an oven, heat it at 135°C for 1.5h, cool it down to room temperature with cold water after the reaction is completed, filter, discard the insoluble matter, and take the upper layer to prepare The reaction product Maillard reaction product was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com