6-series aluminum alloy used for structural part of automobile and preparation method

A technology of automobile structure and aluminum alloy, applied in the field of alloy, to achieve the effect of uniform and dense distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

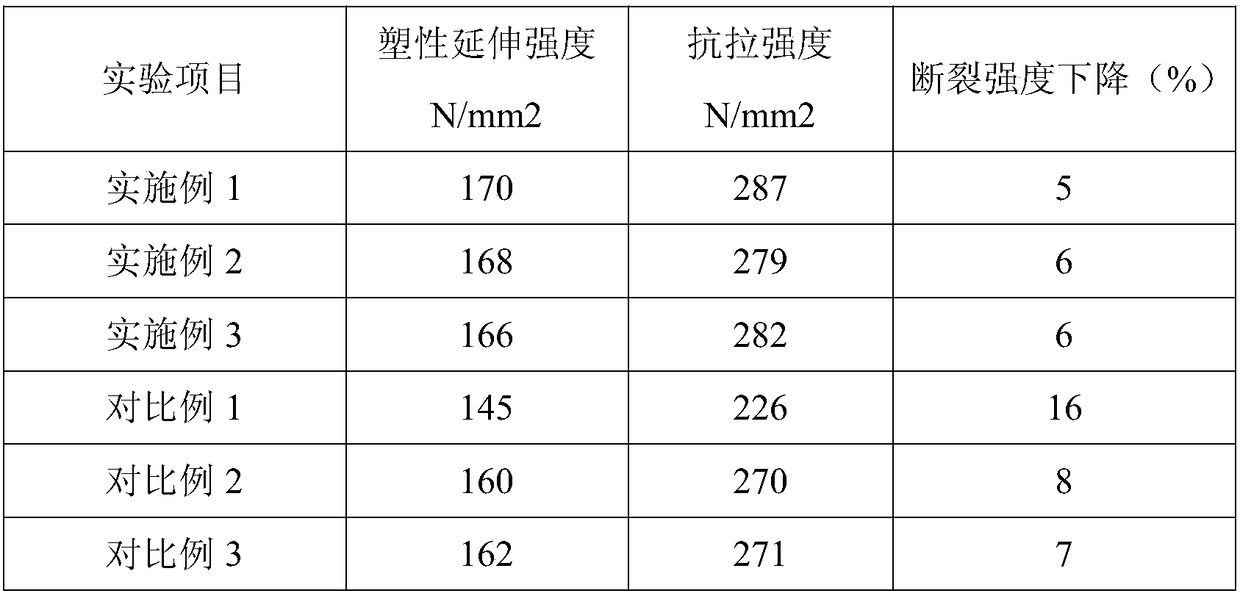

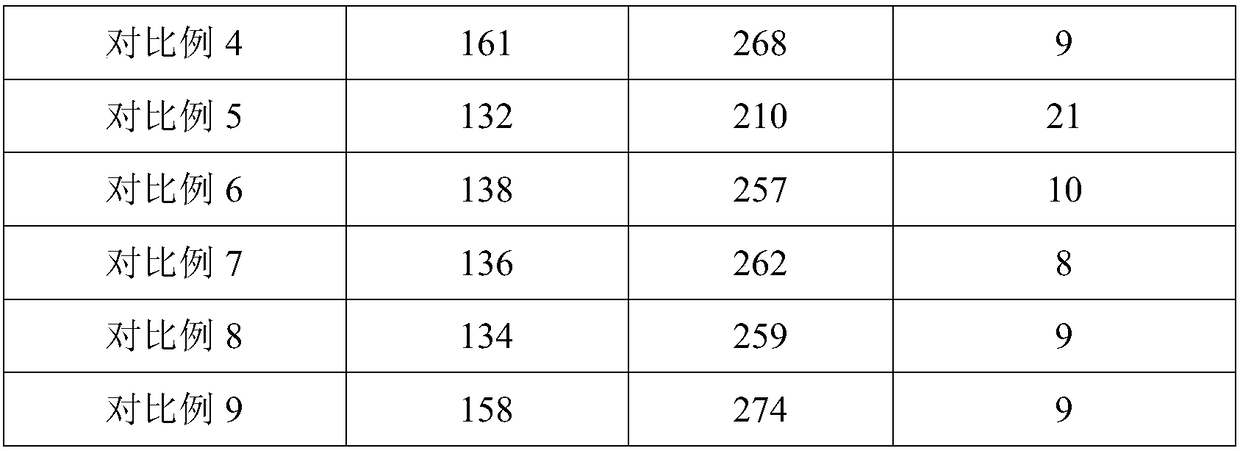

Examples

Embodiment 1

[0027] A 6-series aluminum alloy for automotive structural parts, comprising the following raw materials in parts by weight: 97.5 parts of aluminum, 0.5 parts of silicon, 0.25 parts of iron, 0.15 parts of copper, 0.15 parts of manganese, 1.5 parts of magnesium, 0.15 parts of chromium, zinc 0.075 parts, titanium 0.15 parts, lead 0.003 parts, sodium 0.002 parts, gallium 0.0015 parts, silver fluoride 0.015 parts, sulfur 0.03 parts, phosphorus 0.03 parts.

[0028] A kind of preparation method according to above-mentioned 6 series aluminum alloys for automotive structural parts, comprises the following steps: (1) metal silicon, pure iron, pure copper, pure manganese, pure magnesium, pure chromium, pure zinc, pure titanium, pure Lead, pure sodium, pure gallium and pure aluminum are melted and casted at 900°C for 20-40 minutes, after cooling down to 400-500°C, silver fluoride, phosphorus and sulfur are added, kept for 30 minutes, and the temperature is gradually raised to 800°C for 30...

Embodiment 2

[0030] A 6-series aluminum alloy for automotive structural parts, comprising the following raw materials in parts by weight: 97 parts of aluminum, 0.6 part of silicon, 0.2 part of iron, 0.2 part of copper, 0.1 part of manganese, 1.6 parts of magnesium, 0.1 part of chromium, zinc 0.1 part, titanium 0.1 part, lead 0.005 part, sodium 0.001 part, gallium 0.002 part, silver fluoride 0.01 part, sulfur 0.04 part, phosphorus 0.01 part.

[0031] A kind of preparation method according to above-mentioned 6 series aluminum alloys for automotive structural parts, comprises the following steps: (1) metal silicon, pure iron, pure copper, pure manganese, pure magnesium, pure chromium, pure zinc, pure titanium, pure Lead, pure sodium, pure gallium and pure aluminum were melted and casted at 1100°C for 20 minutes, and after cooling down to 500°C, silver fluoride, phosphorus and sulfur were added, kept for 30 minutes, and the temperature was gradually raised to 700°C for 30 minutes to obtain the ...

Embodiment 3

[0033] A 6-series aluminum alloy for automotive structural parts, comprising the following raw materials in parts by weight: 98 parts of aluminum, 0.4 part of silicon, 0.3 part of iron, 0.1 part of copper, 0.2 part of manganese, 1.4 parts of magnesium, 0.2 part of chromium, zinc 0.05 parts, 0.2 parts of titanium, 0.001 parts of lead, 0.003 parts of sodium, 0.001 parts of gallium, 0.02 parts of silver fluoride, 0.02 parts of sulfur, and 0.05 parts of phosphorus.

[0034] A kind of preparation method according to above-mentioned 6 series aluminum alloys for automotive structural parts, comprises the following steps: (1) metal silicon, pure iron, pure copper, pure manganese, pure magnesium, pure chromium, pure zinc, pure titanium, pure Melt and cast lead, pure sodium, pure gallium and pure aluminum at 800°C for 40 minutes, add silver fluoride, phosphorus and sulfur after cooling down to 400°C, keep the temperature for 30 minutes, and gradually raise the temperature to 900°C for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com