A preparation method and product based on laser-induced superhydrophilic pet surface

A hydrophilic surface, laser-induced technology, used in vacuum evaporation plating, coating, sputtering, etc., can solve the problem of limited large-area production and time-consuming coating process, poor stability of coating wettability materials, etc. problem, to achieve the effect of low production cost, improved hydrophilicity, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

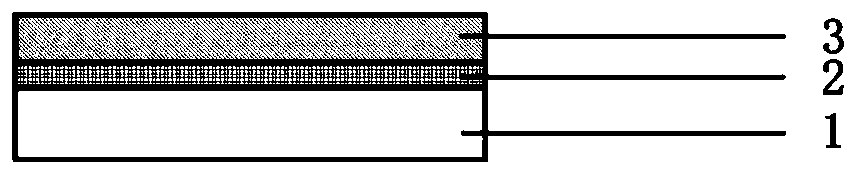

[0026] A preparation method based on laser-induced super-hydrophilic PET surface, the method comprises the following steps:

[0027] Step 1, PET is attached to the glass surface

[0028] Prepare the attachment substrate 1 by spin-coating the absolute ethanol solution 2 on the glass surface, so that the PET film 3 is attached to the substrate surface 1 more smoothly;

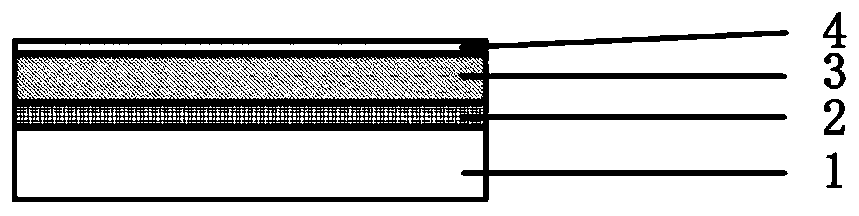

[0029] Step 2, colored layer preparation

[0030] Depositing a colored seed layer 4 with a thickness of 0.03-3 μm on the surface of the sample by sputtering;

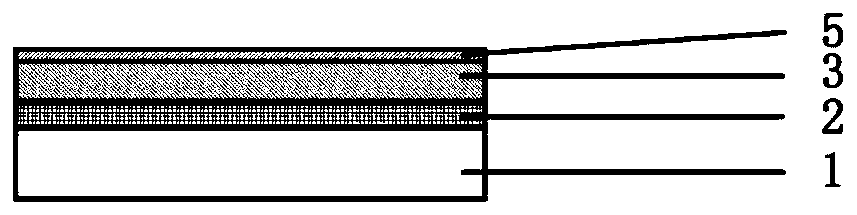

[0031] Step 3, laser-induced processing

[0032] Use a laser marking machine to scan the surface of the PET film to obtain a rough surface 5, that is, a hydrophilic layer, with a pulse repetition frequency of 10-100 kHz, a pulse width of 0.1-0.2, and a laser spot speed of 50-500 mm / s;

[0033] Step 4, alkaline solution corrosion

[0034] Use the solution method to etch the processed surface, adjust the alkaline solution to pH = 8-14, and the corrosion ...

Embodiment 1

[0037] Spin-coat anhydrous ethanol solution on the surface of the glass substrate, and then attach the PET film on the glass substrate; deposit a colored layer with a thickness of 2 μm on the surface of the PET film by sputtering; scan the colored layer with a laser, pulse repetition frequency 50kHz, pulse width 0.15, laser spot speed 300mm / s; the hydrophilic layer on the surface of the PET film was etched with an alkaline solution with a pH of 10, and the etching time was 10min to obtain a superhydrophilic PET surface.

Embodiment 2

[0039] Spin-coat anhydrous ethanol solution on the surface of the glass substrate, and then attach the PET film on the glass substrate; deposit a colored layer with a thickness of 3 μm on the surface of the PET film by sputtering; scan the colored layer with a laser, pulse repetition frequency 100kHz, pulse width 0.2, laser spot speed 500mm / s; the hydrophilic layer on the surface of the PET film was etched with an alkaline solution with a pH of 14 for 30 minutes to obtain a super-hydrophilic PET surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com