Selective catalytic reduction denitration reactor

A denitrification reactor and reactor technology, applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of high investment cost and operation cost, affecting the stable operation of the boiler, and large amount of high-temperature flue gas, etc., to achieve Save investment costs, improve economic and social benefits, and lower flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention. The protection scope of the present invention includes but is not limited to In the following examples, without departing from the spirit and scope of the present application, any modifications made to the details and forms of the technical solutions of the present invention fall within the protection scope of the present invention.

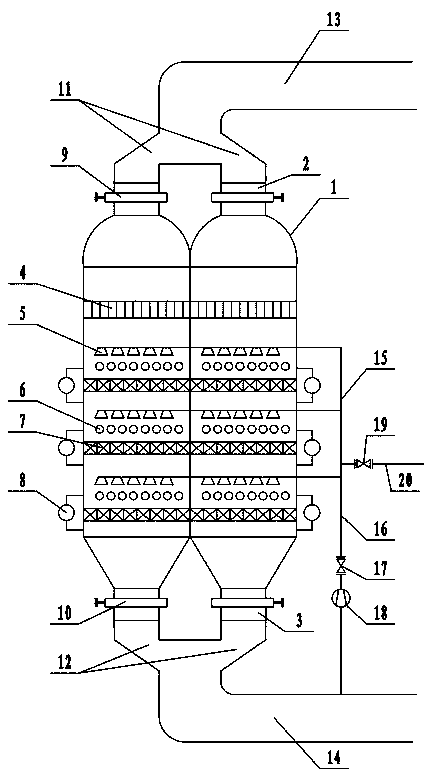

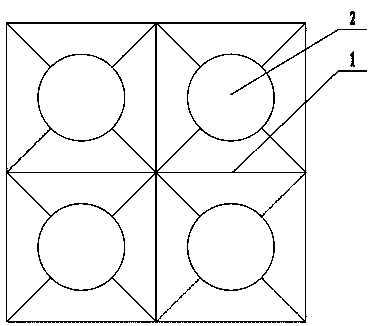

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises reactor body 1, and described reactor body 1 comprises several independent reaction chambers, and the top and the bottom of each reaction chamber of described reactor body 1 are all provided with reactor inlet 2 and reactor outlet 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com