Preparation method for organic-inorganic blend membrane

A blended membrane and inorganic technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, special compound water treatment, etc., can solve the problem of large loss, difficult recovery, affecting catalyst stability and light Catalytic activity and other issues to achieve the effect of prolonging service life, accelerating degradation, and increasing reactive sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

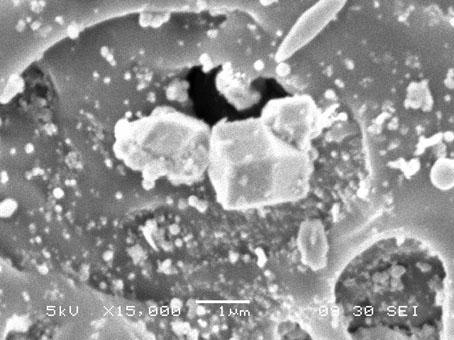

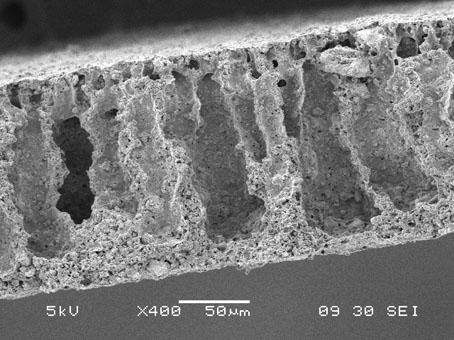

Image

Examples

Embodiment 1

[0034] One of the embodiments of the preparation method of an organic-inorganic blend membrane of the present invention comprises the following steps:

[0035]Accurately weigh 15g of polyester-type thermoplastic polyurethane particles with a Shore hardness of 55A and 100g of N,N-dimethylformamide solution into a beaker, heat and stir at 40°C with a magnetic stirrer to make the polyurethane particles completely be dissolved in a solvent to obtain a polyurethane polymer solution with a mass fraction of 13%; accurately weigh 0.58g polyethylene glycol 1000 and dissolve it in 5g of N,N-dimethylformamide solution to obtain a completely dissolved polyethylene glycol alcohol solution; add the above-mentioned completely dissolved polyethylene glycol solution into the polyurethane polymer solution, and stir for 10 minutes with a magnetic stirrer to ensure that the polyethylene glycol solution is evenly dispersed in the polyurethane polymer solution; Add 15.76g negative oxygen ion powder...

Embodiment 2

[0038] One of the embodiments of the preparation method of an organic-inorganic blend membrane of the present invention comprises the following steps:

[0039] Accurately weigh 12g of polyester-type thermoplastic polyurethane particles with a Shore hardness of 60A and 108g of N,N-dimethylacetamide solution into a beaker, heat and stir at 45°C with a magnetic stirrer to make the polyurethane particles completely Dissolve in a solvent to obtain a polyurethane polymer solution with a mass fraction of 10%; accurately weigh 0.72g polyethylene glycol 1000 and dissolve it in 5g of N,N-dimethylformamide solution to obtain a completely dissolved polyethylene glycol alcohol solution; add the above-mentioned completely dissolved polyethylene glycol solution into the polyurethane polymer solution, and stir for 15 minutes with a magnetic stirrer to ensure that the polyethylene glycol solution is evenly dispersed in the polyurethane polymer solution; Add 20.46g negative oxygen ion powder in...

Embodiment 3

[0043] One of the embodiments of the preparation method of an organic-inorganic blend membrane of the present invention comprises the following steps:

[0044] Accurately weigh 13g of polyester-type thermoplastic polyurethane particles with a Shore hardness of 65A and 74g of N,N-dimethylacetamide solution into a beaker, heat and stir at 40°C with a magnetic stirrer to make the polyurethane particles completely be dissolved in a solvent to obtain a polyurethane polymer solution with a mass fraction of 15%; accurately weigh 0.84g polyethylene glycol 1000 and dissolve it in 5g of N,N-dimethylformamide solution to obtain a completely dissolved polyethylene glycol alcohol solution; add the above-mentioned completely dissolved polyethylene glycol solution into the polyurethane polymer solution, and stir for 15 minutes with a magnetic stirrer to ensure that the polyethylene glycol solution is evenly dispersed in the polyurethane polymer solution; Add 16.38g negative oxygen ion powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com