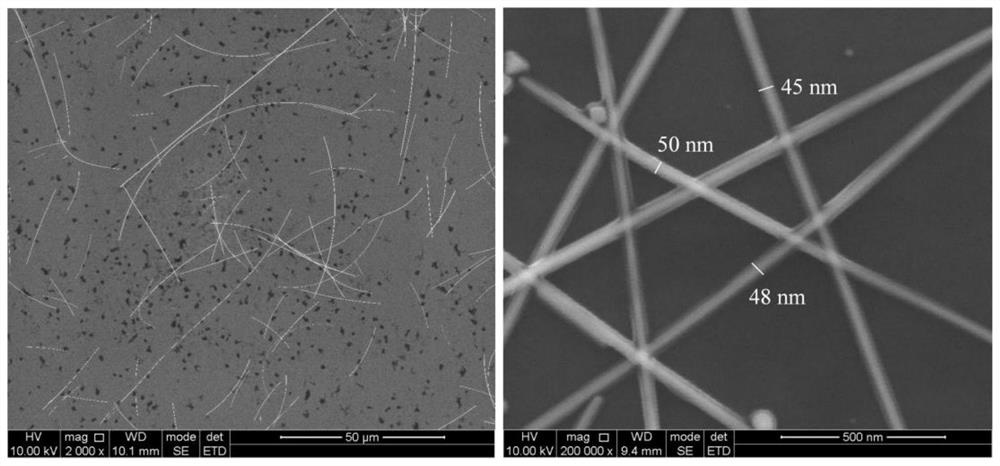

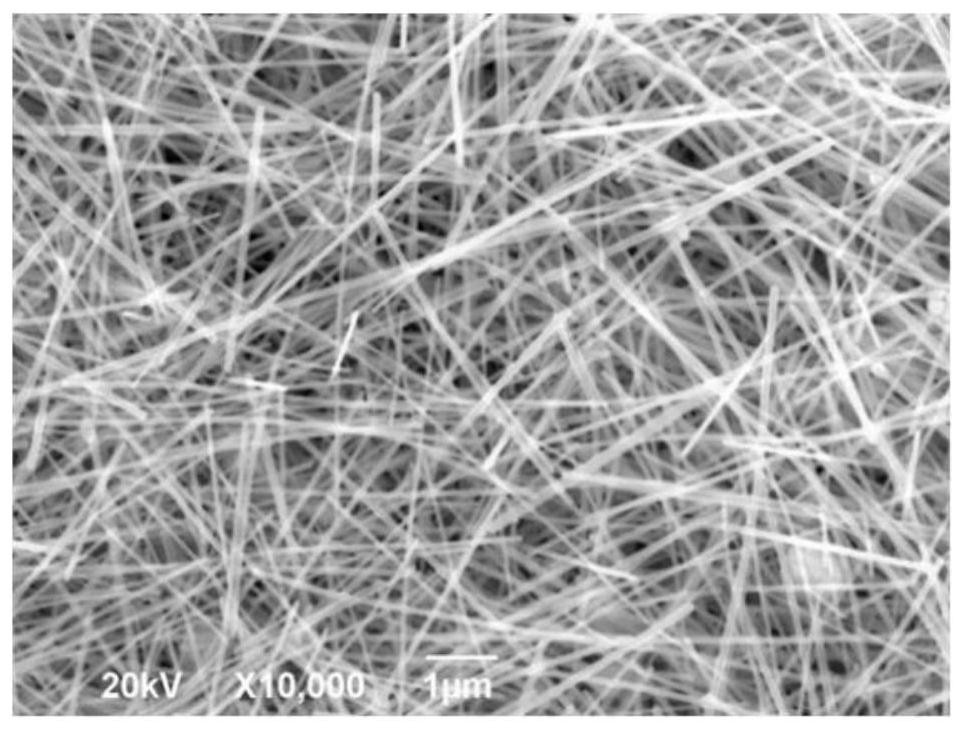

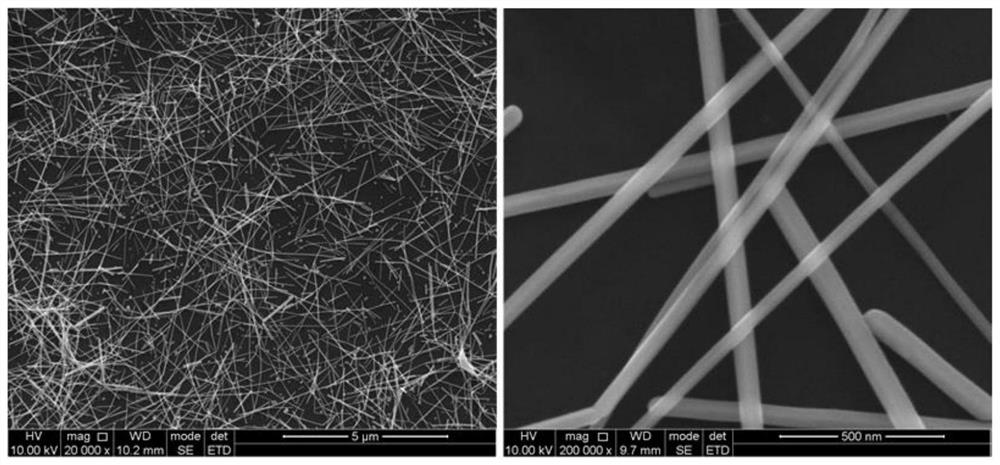

A controllable preparation method of uniform silver nanowires with small diameter and ultrahigh aspect ratio

A nano-silver wire and aspect ratio technology, which is applied in the field of controllable preparation of uniform nano-silver wires, can solve the problems of large diameter and long time-consuming of nano-silver wires, and achieve the effects of short reaction time, simple operation and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for the controllable preparation of a uniform silver nanowire with a small diameter and an ultrahigh aspect ratio, characterized in that it comprises the following steps:

[0034] Step 1, preparing an ethylene glycol solution of polyvinylpyrrolidone, adding inducers chloride salt, bromide salt and iron salt to it, and mixing evenly to obtain a mixed solution A;

[0035] Step 2, prepare the ethylene glycol solution B of silver nitrate;

[0036] Step 3. Slowly add solution B to mixed solution A, mix evenly, and place in a reaction kettle;

[0037] Step 4, heating the mixed solution in the reaction kettle to 155-165°C, keeping it warm until the reaction is complete to obtain the silver nanowire stock solution;

[0038] Step 5. After the nano-silver wire stock solution obtained in step 4 is cooled, it is centrifuged and washed to obtain uniform nano-silver wires with small diameter and super high aspect ratio.

[0039] Preferably, the K value of polyvinylpyrrolid...

Embodiment

[0049] Using ethylene glycol as a solvent, prepare a solution with a concentration of polyvinylpyrrolidone of 0.15mol / L; add NaCl, NaBr and FeCl to it 3 , so that Cl - The total concentration is 600μmol / L, Br - Concentration is 100μmol / L, Fe 3+ The concentration is 1.5 μmol / L, mix evenly to obtain the mixed solution A. Using ethylene glycol as a solvent, prepare silver nitrate solution B with a concentration of 0.1 mol / L. Slowly add solution B into mixed solution A, and mix well so that Ag + The ratio of concentration to polyvinylpyrrolidone is 1:1.5. The mixed solution was charged into a Teflon-lined stainless steel reaction kettle. Put the reaction kettle into a thermostat, and raise the temperature to 160° C. at a rate of 4° C. / min, and keep the temperature for 2 hours to obtain a silver nanowire stock solution. After the silver nano wire stock solution is cooled to room temperature, it is centrifuged at 6000 rpm for 5 minutes, and after using a mixture of ethanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com