Preparation method of cobaltic fluoride particles

A technology of cobalt trifluoride particles and granules, applied in the direction of cobalt halide and other directions, can solve problems such as hidden dangers of production safety, low production efficiency, and increase the difficulty of production, and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

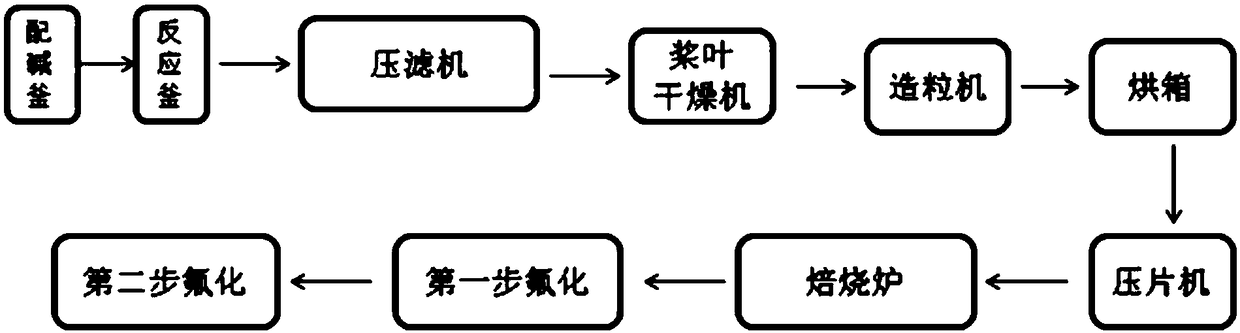

[0023] The specific process is as figure 1 shown.

[0024] (1) Ingredients:

[0025] A, drop into cobalt chloride 282kg, aluminum trichloride 12kg, zinc chloride 6kg in reactor (stirred tank formula), promptly add up to drop into cobalt salt mixture 120kg;

[0026] b. Add 1500kg of deionized water into the reactor, stir and dissolve the cobalt salt mixture to form a solution;

[0027] c. Configure 550L of 5% caustic soda in the caustic soda mixing kettle;

[0028] (2) Reaction:

[0029] d, open the reactor agitator, pump 550L of caustic soda with 5% of the caustic soda tank into the reactor;

[0030] e, carry out reaction under stirring condition 10min, stop stirring and generate cobalt hydroxide, zinc hydroxide, aluminum hydroxide precipitation, finally complete reaction and be weak alkaline pH and be 8;

[0031] (3) Press filtration and granulation:

[0032] f, pressure filtration: use the transfer pump at the bottom of the reaction kettle to put cobalt hydroxide, zinc...

Embodiment 2

[0051] (1) Preparation of cobalt salt solution: 94 parts of cobalt chloride, aluminum trichloride part and zinc chloride part are put into the reactor, fully mixed, then 500 parts of deionized water are added, stirred and dissolved to form cobalt salt solution;

[0052] (2) Reaction: pump 150 parts of caustic soda with a mass concentration of 2%-12% into the cobalt salt solution obtained in step (1), stir and react for 20min at a rotating speed of 20r / min, and let it stand for precipitation;

[0053] (3) Pressure filtration and granulation: the precipitate obtained at the bottom of the reaction kettle in step (2) is put into a plate and frame filter press for pressure filtration through a delivery pump, and then washed with water for a second pressure filtration, and the obtained filter cake is dried, and then early granulated On-machine granulation with a mesh number of 20; finally, dry the obtained granules at 60°C for 40 hours and cool naturally;

[0054] (4) Tablet roasting:...

Embodiment 3

[0059] (1) Preparation of cobalt salt solution: 94 parts of cobalt chloride, aluminum trichloride part and zinc chloride part are put into the reactor, fully mixed, then 500 parts of deionized water are added, stirred and dissolved to form cobalt salt solution;

[0060] (2) Reaction: pump 200 parts of caustic soda with a mass concentration of 2%-12% into the cobalt salt solution obtained in step (1), stir and react for 2min at a rotating speed of 200r / min, and let stand for precipitation;

[0061] (3) Pressure filtration and granulation: the precipitate obtained at the bottom of the reaction kettle in step (2) is put into a plate and frame filter press for pressure filtration through a delivery pump, and then washed with water for a second pressure filtration, and the obtained filter cake is dried, and then early granulated Granulate on the machine with a mesh number of 25; finally dry the obtained granules at 100°C for 10 hours, and cool naturally;

[0062] (4) Tablet roastin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com