Rapid starting method for SNAD process in upflow micro-aerobic membrane bioreactor

A membrane bioreactor, rapid start-up technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, biological water/sewage treatment, etc., can solve problems such as instability and long start-up period of SNAD process, and achieve cost Low cost, small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

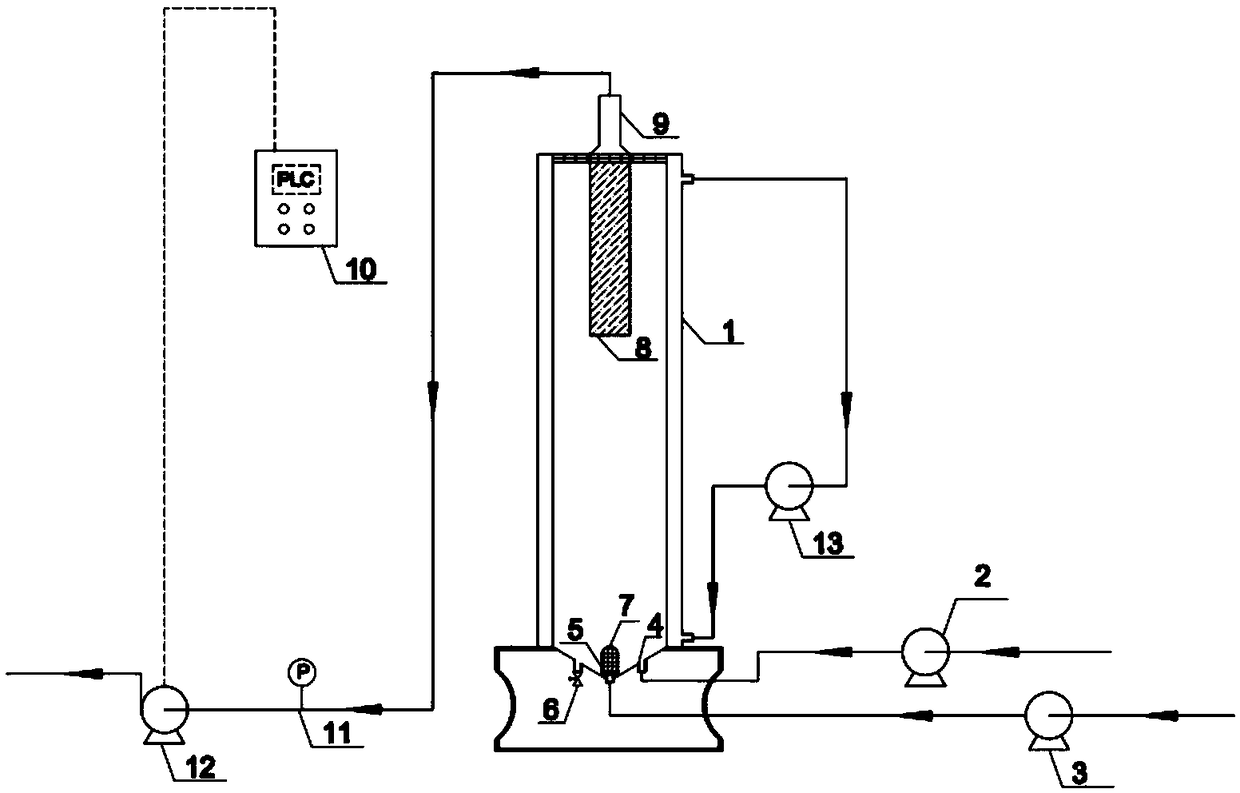

[0031] A method for quickly starting the SNAD process in an upflow type micro-aerobic membrane bioreactor, mainly comprising the following steps:

[0032] (1) Inoculation of activated sludge and equipment

[0033] Such as figure 1 As shown in , the upflow micro-oxygen membrane bioreactor SNAD process quick start device, reactor 1 is a cylinder with interlayer, inner diameter 0.07m, outer diameter 0.09m, height 1.2m, effective volume 4L. Reactor 1 is equipped with a polyvinylidene fluoride (PVDF) hollow fiber membrane 8 with a pore diameter of 0.3 μm and an effective membrane area of 0.3 m 2 .

[0034] The water inlet pipe connected to the bottom water inlet 4 of the reactor 1 is connected to the water inlet pump 2, the aeration pipe connected to the aeration port 5 at the bottom of the reactor 1 is connected to the air pump 3, and the aeration pipe connected to the aeration port 5 The head 7 is a cylindrical titanium aeration head with a pore size of 5 microns, and the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com