Method for removing heavy metal in rare earth extraction waste water

An extraction and wastewater technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high price of sodium sulfide or recapture agent, difficulty in treatment and recovery of heavy metals, excessive heavy metal elements, etc. In large-scale production, stable treatment effect, and the effect of reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

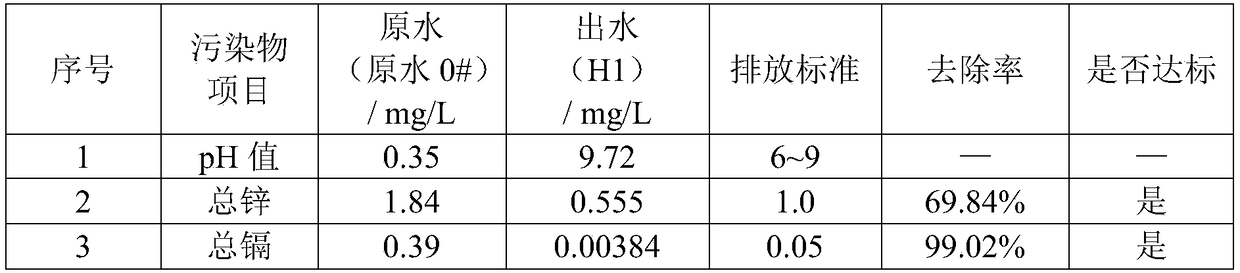

Embodiment 1

[0026] A method for removing heavy metals in rare earth extraction wastewater of the present invention comprises the following steps:

[0027] (1) Add precipitant sodium hydroxide to 20L rare earth extraction wastewater for pretreatment, press filter after pretreatment to remove residue, waste liquid enters reaction tank for follow-up treatment, and the pH value of the waste liquid obtained is 10;

[0028] (2) Add coagulant aid polyaluminium chloride in the waste liquid after step (1), by waste liquid volume, the add-on of coagulant aid is 100mg / m 3 , and then put the waste liquid and coagulant into the reaction chamber of the electrocoagulation reactor with a peristaltic pump, start the electrocoagulation reactor for flocculation treatment, and the current density is 150A / m 2 After the flocculation treatment is completed, the adsorbent polyacrylamide is added to the water outlet of the electrocoagulation reactor, and then the mixed solution containing flocs after the floccula...

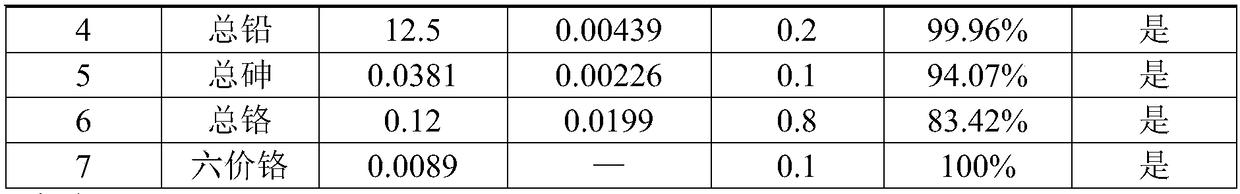

Embodiment 2

[0034] A method for removing heavy metals in rare earth extraction wastewater of the present invention comprises the following steps:

[0035] (1) Add quicklime as a precipitating agent to 20L of rare earth extraction wastewater for pretreatment, press filter to remove residue after pretreatment, and the waste liquid enters the reaction tank for subsequent treatment, and the pH value of the obtained waste liquid is 9.5;

[0036] (2) Add coagulant aluminum sulfate to the waste liquid after step (1), in terms of waste liquid volume, the add-on of coagulant is 50mg / m 3 , and then put the waste liquid and coagulant into the reaction chamber of the electrocoagulation reactor with a peristaltic pump, start the electrocoagulation reactor for flocculation treatment, and the current density is 100A / m 2 After the flocculation treatment is completed, the adsorbent polyacrylamide is added to the water outlet of the electrocoagulation reactor, and then the mixed solution containing flocs a...

Embodiment 3

[0040] A method for removing heavy metals in rare earth extraction wastewater of the present invention comprises the following steps:

[0041] (1) Add precipitant lime to 20L rare earth extraction wastewater for pretreatment, press filter after pretreatment to remove residue, waste liquid enters the reaction tank for subsequent treatment, and the pH value of the obtained waste liquid is 9.5;

[0042] (2) Add coagulant aluminum sulfate to the waste liquid after step (1), in terms of waste liquid volume, the add-on of coagulant is 50mg / m 3 , and then put the waste liquid and coagulant into the reaction chamber of the electrocoagulation reactor with a peristaltic pump, start the electrocoagulation reactor for flocculation treatment, and the current density is 150A / m 2 After the flocculation treatment is completed, the adsorbent polyacrylamide is added to the water outlet of the electrocoagulation reactor, and then the mixed solution containing flocs after the flocculation treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com