PbTe/CdTe double quantum dot codoping borosilicate glass and preparation technology thereof

A borosilicate glass, double quantum dot technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problem of photoelectric conversion rate to be further improved, narrow photoluminescence spectral range, low spectral coverage, etc. problem, to achieve good optical properties, reduce softening point, reduce the effect of light reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

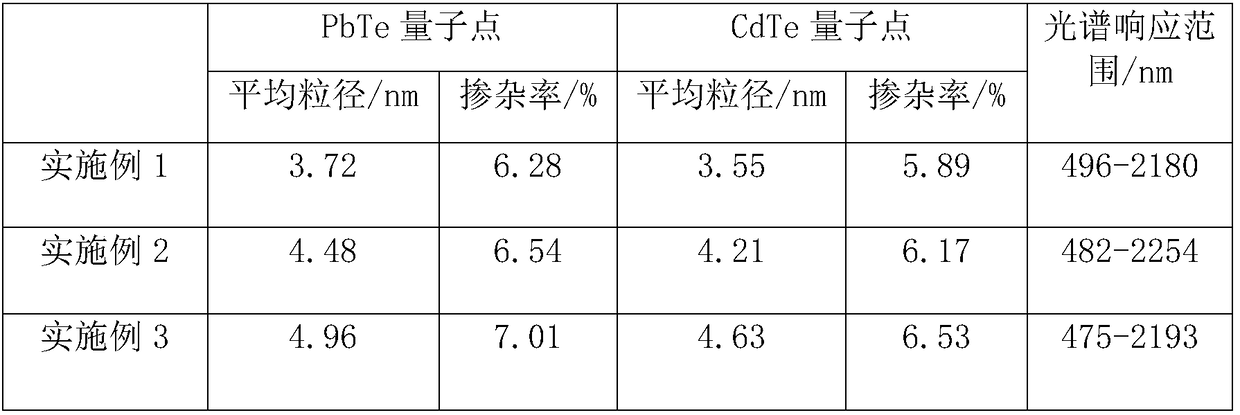

Embodiment 1

[0018] A PbTe / CdTe double quantum dot co-doped borosilicate glass, including the following mole percentage raw materials: SiO 2 45%, B 2 o 3 12%, Na 2 O 8%, Al 2 o 3 3%, ZnTe 9%, PbO 2.4%, CdO 2%, CaO 9%, ZnO6%, SrF 2 2%, Mg 2 B 2 o 5 0.6%, La 2 o 3 +Pr 2 o 3 +Nb 2 o 5 1%; among them, La 2 o 3 、Pr 2 o 3 with Nb 2 o 5 The molar ratio is 2:1.5:1.

[0019] The above-mentioned preparation process of PbTe / CdTe double quantum dot co-doped borosilicate glass comprises the following steps:

[0020] S1: Mix glass raw materials according to mole percentage, heat up to 1250°C under nitrogen, keep warm and melt for 1 hour to obtain glass melt;

[0021] S2: When the glass melt drops to 1000°C, it is cast onto a graphite mold for molding, and then annealed at 550°C for 3 hours;

[0022] S3: After heating the annealed glass at a constant temperature of 550°C for 1 hour, the temperature was raised to 700°C at a rate of 3°C / min, kept for 1 hour, then raised to 820°C ...

Embodiment 2

[0024] A PbTe / CdTe double quantum dot co-doped borosilicate glass, including the following mole percentage raw materials: SiO 2 60%, B 2 o 3 9%, Na 2 O 6%, Al 2 o 3 1.5%, ZnTe 5.8%, PbO 1.8%, CdO 1.5%, CaO 7%, ZnO 5%, SrF 2 1.5%, Mg 2 B 2 o 5 0.3%, La 2 o 3 +Pr 2 o 3 +Nb 2 o 5 0.6%; of which, La 2 o 3 、Pr 2 o 3 with Nb 2 o 5 The molar ratio is 2.5:1.7:1.

[0025] Preparation technology is with embodiment 1, difference is:

[0026] S1: The melting temperature is 1300°C;

[0027]S2: The casting temperature is 1100°C, and the annealing temperature is 550°C;

[0028] S3: Heat treatment process: After heating the glass at constant temperature for 1.5 hours at 575°C, the temperature was raised to 725°C at a rate of 4°C / min, kept for 3 hours, then raised to 860°C at a rate of 12°C / min, kept for 2 hours, and then heated at a rate of 18°C / min. The temperature was lowered to 575°C at a rate of 9°C / min, and finally to room temperature at a rate of 9°C / min.

Embodiment 3

[0030] A PbTe / CdTe double quantum dot co-doped borosilicate glass, including the following mole percentage raw materials: SiO 2 75%, B 2 o 3 6%%, Na 2 O 4%, Al 2 o 3 0.1%, ZnTe 2.5%, PbO 1.2%, CdO 1%, CaO 5%, ZnO 4%, SrF 2 1%, Mg 2 B 2 o 5 0.1%, La 2 o 3 +Pr 2 o 3 +Nb 2 o 5 0.1%; among them, La 2 o 3 、Pr 2 o 3 with Nb 2 o 5 The molar ratio is 6:1.6:1.

[0031] Preparation technology is with embodiment 1, difference is:

[0032] S1: The melting temperature is 1350°C;

[0033] S2: The casting temperature is 1200°C, and the annealing temperature is 570°C;

[0034] S3: Heat treatment process: After heating the glass at a constant temperature of 600°C for 2 hours, the temperature was raised to 750°C at a rate of 5°C / min, kept for 5 hours, then raised to 900°C at a rate of 15°C / min, kept for 1-3 hours, and then heated at a rate of 20°C / min The temperature was lowered to 600°C, and finally to room temperature at a rate of 10°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com