Aramid fiber coating liquid and lithium-ion battery separator and preparation methods thereof

A lithium-ion battery and coating liquid technology, applied in secondary batteries, battery pack parts, coatings, etc., can solve problems such as poor thermal stability, improve bonding performance, high extraction efficiency, improve energy density and Effects of oxidation resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

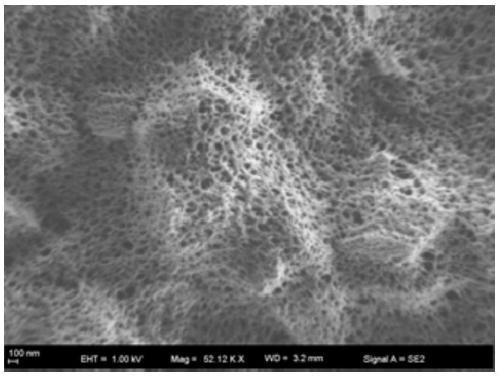

Image

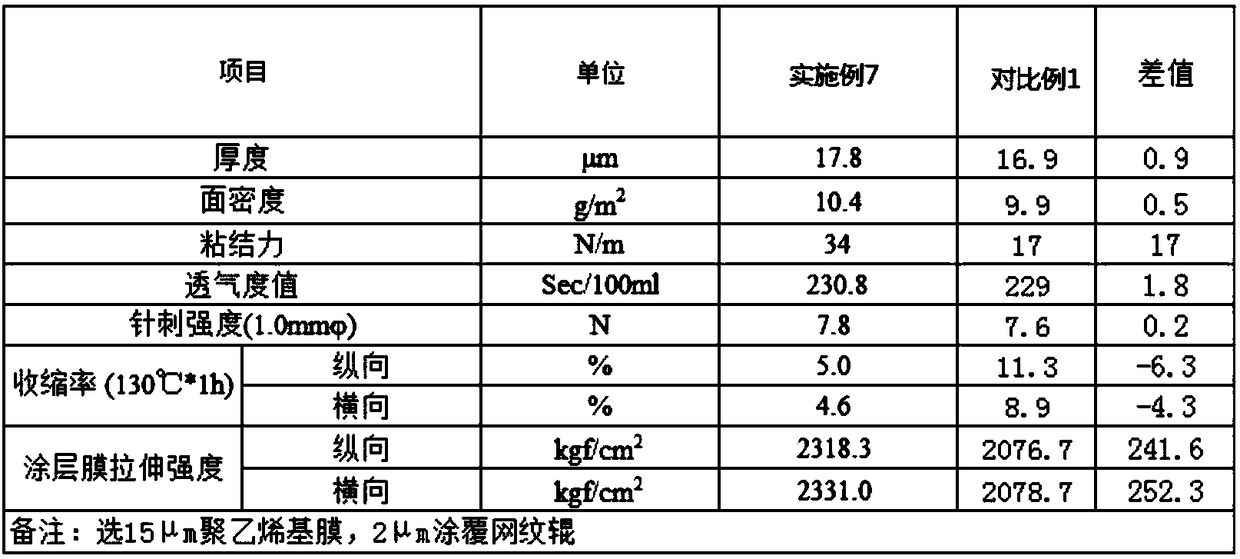

Examples

Embodiment 1

[0040] This embodiment provides a kind of aramid fiber coating solution for preparing coated diaphragm, which comprises by weight parts:

[0041] 8 parts of aramid fiber, 5 parts of polyvinylidene fluoride, 10 parts of inorganic filler, 10 parts of dimethyl carbonate, 115 parts of dimethylacetamide.

[0042] Its preparation method includes:

[0043] a. polyvinylidene fluoride is mixed with 50 parts of dimethylacetamide to obtain a tackifier;

[0044] b. mixing the inorganic filler with 30 parts of dimethylacetamide to prepare the inorganic filler slurry;

[0045] c. Disperse aramid fiber in 35 parts of dimethylformamide, stir for 0.5h, then add dimethyl carbonate, stir at 1300rmp for 0.5h, mix well with tackifier and inorganic filler slurry Stir for 2h, that is.

Embodiment 2

[0047] This embodiment provides a kind of aramid fiber coating solution for preparing coated diaphragm, which comprises by weight parts:

[0048] 3 parts of aramid fiber, 1 part of polyvinylidene fluoride, 20 parts of inorganic filler, 4 parts of dimethyl carbonate, 50 parts of N-methylpyrrolidone, 15 parts of isopropanol.

[0049] Its preparation method includes:

[0050] a. mixing polyvinylidene fluoride with 20 parts of N-methylpyrrolidone to obtain a tackifier;

[0051] b. mixing the inorganic filler with isopropanol to prepare the inorganic filler slurry;

[0052] c. Disperse the aramid fiber in 30 parts of N-methylpyrrolidone, stir for 0.5h, then add dimethyl carbonate, stir at 700rmp for 1h, stir well, mix with tackifier and inorganic filler slurry and stir 1h, that is.

Embodiment 3

[0054] This embodiment provides a kind of aramid fiber coating solution for preparing coated diaphragm, which comprises by weight parts:

[0055] 5 parts of aramid fiber, 2.5 parts of polytetrafluoroethylene, 15 parts of boehmite, 6.5 parts of dimethyl carbonate, 35 parts of dimethylacetamide, 22 parts of tripropylene glycol, and 32.5 parts of dimethylformamide.

[0056] Its preparation method includes:

[0057] a. mixing polyvinylidene fluoride with dimethylacetamide to obtain a tackifier;

[0058] b. Boehmite is mixed with tripropylene glycol to obtain an inorganic filler slurry;

[0059] c. Disperse aramid fiber in dimethylformamide, stir for 1 hour, then add dimethyl carbonate, stir at 1000rmp for 0.75 hour, mix well with tackifier and inorganic filler slurry and stir for 1.5 hour, Instantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com