Preparation method of low free phenol content sulfurized calcium alkyl phenolate

A technology for sulfurized calcium alkyl phenate and preparation process, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of troublesome process, secondary pollution, complicated process and the like, and achieves simple and easy process operation and mild reaction conditions. , the effect of improving water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

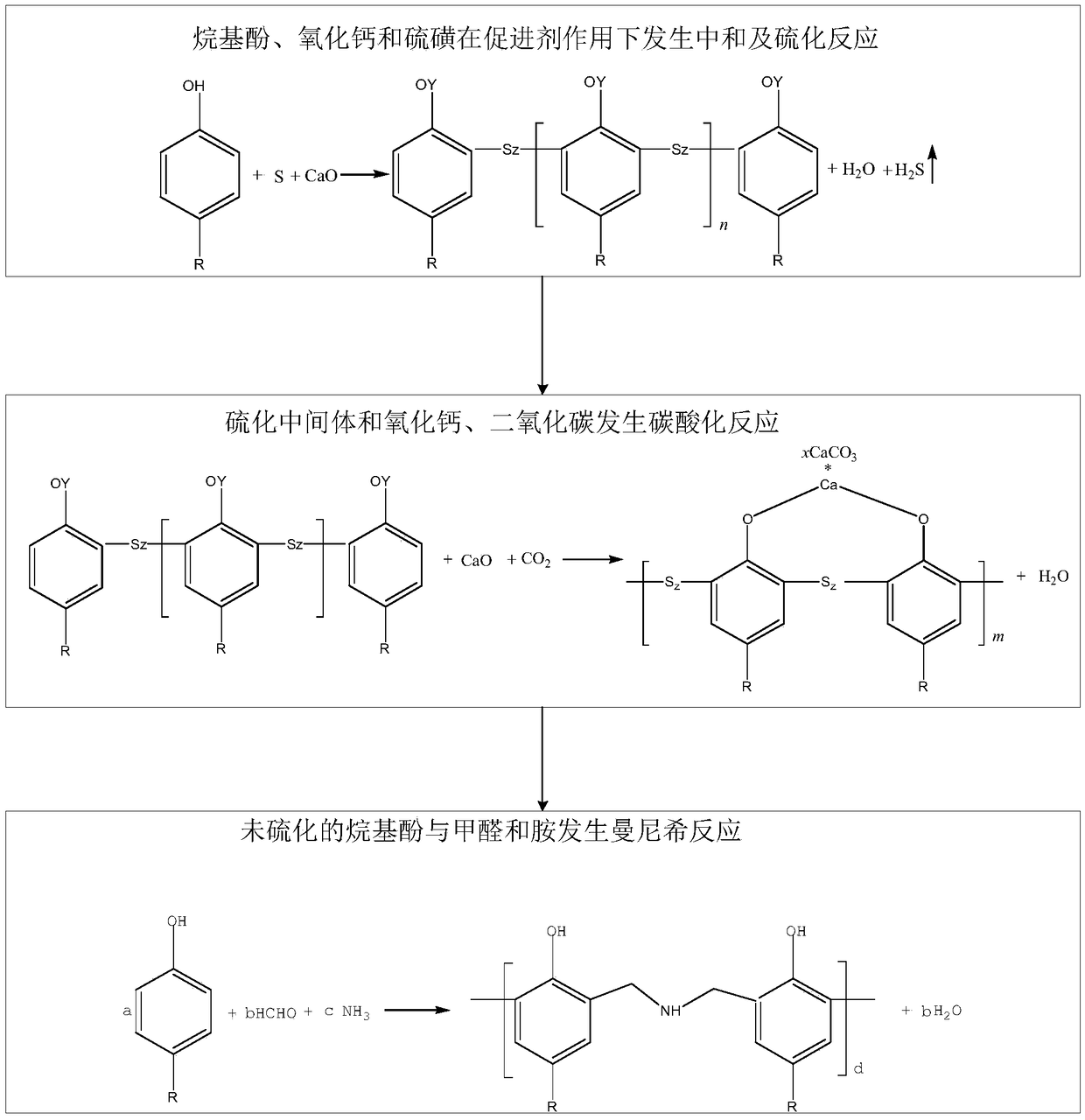

Method used

Image

Examples

Embodiment 1

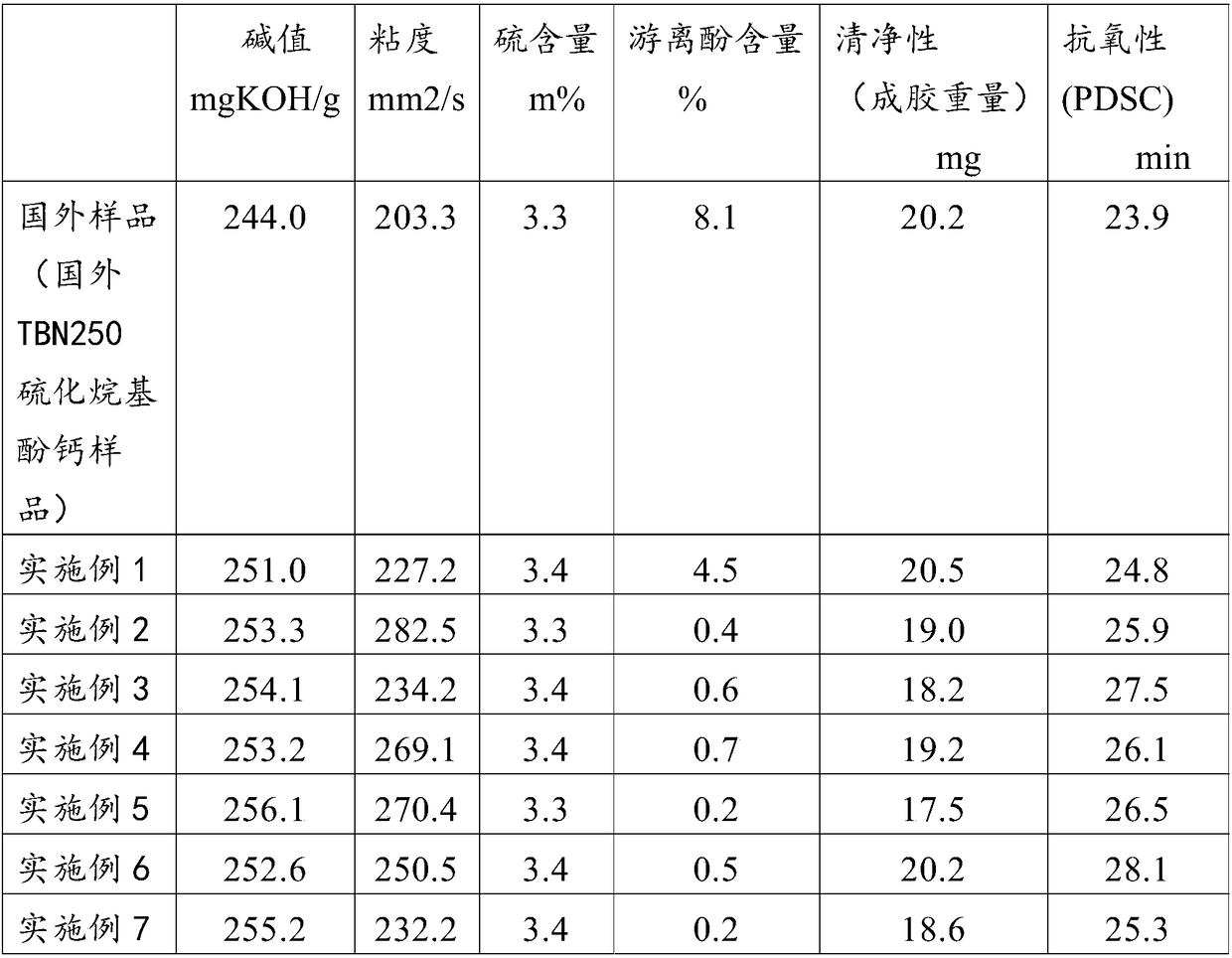

[0031] Embodiment 1 (comparative experiment):

[0032] Add 60g of alkylphenol, 55g of base oil, 15g of sulfur, 10g of calcium oxide, 2g of tetradecanoic acid, and 1g of polyisobutylene succinic anhydride into a 500mL four-necked bottle, raise the temperature to 100°C for neutralization reaction for 1 hour, and continue to heat up to 160°C , add 9g accelerator ethylene glycol to carry out vulcanization reaction for 5 hours, then add 12g calcium oxide (adding in three times), charge carbon dioxide 5.5L to carry out carbonation reaction. After the reaction was completed, the temperature was lowered to 120° C., and 5 g of filter aid was added to remove the slag by filtration to obtain 149 g of finished sulfurized calcium alkylphenate.

Embodiment 2

[0034] Add 60g of alkylphenol, 60g of base oil, 15g of sulfur, 10g of calcium oxide, 2g of tetradecanoic acid, and 1g of polyisobutylene succinic anhydride into a 500mL four-necked bottle, raise the temperature to 100°C for neutralization reaction for 1 hour, and continue to heat up to 160°C , add 9g accelerator ethylene glycol to carry out vulcanization reaction for 5 hours, add calcium oxide 12g again (adding in three times), charge carbon dioxide 5.5L to carry out carbonation reaction. After the reaction, the temperature of the system was lowered to 30-60°C, 5.5g of polyisobutylene succinimide and 1.0g of paraformaldehyde were added, and the temperature was raised slowly, controlling the heating time for 4 hours to raise the temperature to 220°C, during which the water generated by the reaction was removed. After the reaction was completed, the temperature was lowered to 100° C., and 5 g of filter aid was added to remove the slag by filtration to obtain 158 g of finished pro...

Embodiment 3

[0036]Add 60g of alkylphenol, 60g of base oil, 15g of sulfur, 10g of calcium oxide, 2g of tetradecyl carbonic acid, and 1g of octadecanol into a 500mL four-necked bottle, raise the temperature to 100°C for neutralization reaction for 1 hour, and continue to heat up to 160°C. Add 9g of accelerator ethylene glycol to carry out vulcanization reaction for 5 hours, add 12g of calcium oxide again (adding in two times), and charge 5.5L of carbon dioxide to carry out carbonation reaction. After the reaction, the temperature of the system was lowered to 30-60°C, 1.2g of diethylenetriamine and 0.5g of paraformaldehyde were added, and the temperature was raised slowly. The heating time was controlled for 2 hours and the temperature was raised to 160°C, during which the water generated by the reaction was removed. After the reaction was completed, the temperature was lowered to 120° C., and 5 g of filter aid was added to remove the slag by filtration to obtain 152 g of finished product of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com