Alcohol double-ring production method using cassava as main raw material

A production method and double-ring technology, which can be used in biofuels, fermentation and other directions, can solve the problems of difficult material and liquid transportation, increased power consumption, inhibiting yeast growth, etc. and power consumption, eliminating the effect of competitive inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

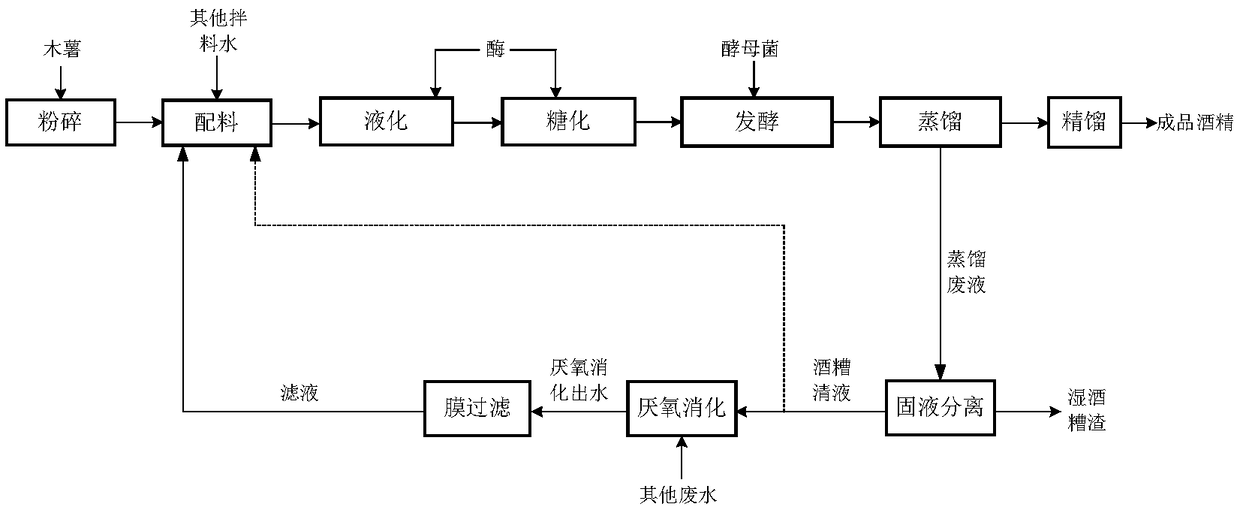

Image

Examples

Embodiment 1

[0034] Take 4000g of cassava flour, add recycled water and add tap water to 12L, add 560μL of high-temperature-resistant α-amylase, stir evenly, heat to 95°C and maintain for 120min; cool down to 60°C, add 6mL of glucoamylase, stir well and keep warm Saccharification for 20min. After the saccharification is completed, the temperature is lowered to 30° C., and 10% (v / v) yeast seed liquid is inserted to start fermentation. After fermentation, alcohol, distiller's grains and fine tower residue are obtained through distillation, rectification and other processes. The distiller's grains are centrifuged to obtain the distiller's grains clear liquid, and 90% of the distiller's grains clear liquid enters the anaerobic digestion reactor for treatment, and biogas is collected during the treatment process. Anaerobic digestion effluent is passed through ultrafiltration membrane to obtain membrane filtrate (ultrafiltration membrane molecular weight cut-off 200kDA, membrane surface flow ve...

Embodiment 2

[0036] Take 100g of cassava flour, add recycled water and tap water to 220mL, add 21μL of high-temperature-resistant α-amylase, stir well, heat to 95°C and maintain for 120min; cool down to 60°C, add 180μL of glucoamylase, stir well, and keep warm for saccharification 20min. After the saccharification is completed, the temperature is lowered to 30° C., and 10% (v / v) yeast seed liquid is inserted to start fermentation. After the fermentation is over, alcohol, distiller's grains and fine tower residue are obtained through processes such as distillation and rectification. The distiller's grains are centrifuged to obtain the distiller's grains clear liquid, and 80% of the distiller's grains clear liquid enters the anaerobic digestion reactor for treatment, and biogas is collected during the treatment process. The anaerobic digestion effluent is passed through a microfiltration membrane to obtain a membrane filtrate (the molecular weight cut-off of the microfiltration membrane is ...

Embodiment 3

[0038]Take 300kg of cassava flour, add recycled water and tap water to 900L, add 42mL of high-temperature-resistant α-amylase, stir well, heat to 95°C and maintain for 120min; cool down to 58°C, add 450mL of glucoamylase, stir well, and keep warm for saccharification 20min. After the saccharification is completed, the temperature is lowered to 30° C., and 10% (v / v) yeast seed liquid is inserted to start fermentation. After the fermentation is over, alcohol, distiller's grains and fine tower residue are obtained through processes such as distillation and rectification. The distiller's grains are centrifuged to obtain distiller's grains, and 70% of the distiller's grains are processed in an anaerobic digestion reactor, and biogas is collected during the treatment process. The anaerobic digestion effluent is passed through the ultrafiltration membrane to obtain the membrane filtrate (the ultrafiltration membrane molecular weight cut-off is 300kDA, the membrane surface flow veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com