Aluminum alloy mold surface treatment process

A surface treatment, aluminum alloy technology, applied in the direction of metal material coating process, surface reaction electrolytic coating, liquid chemical plating, etc. The effect of strength, improved molding effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

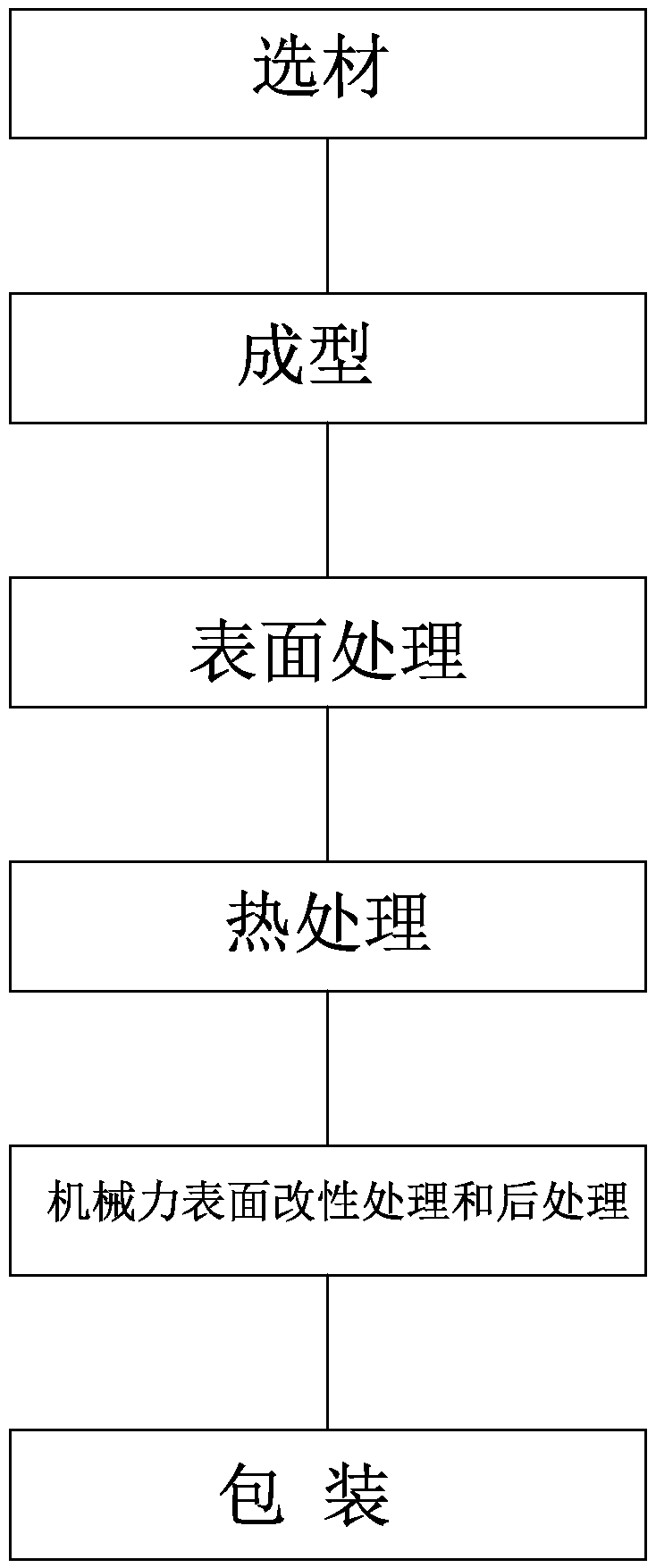

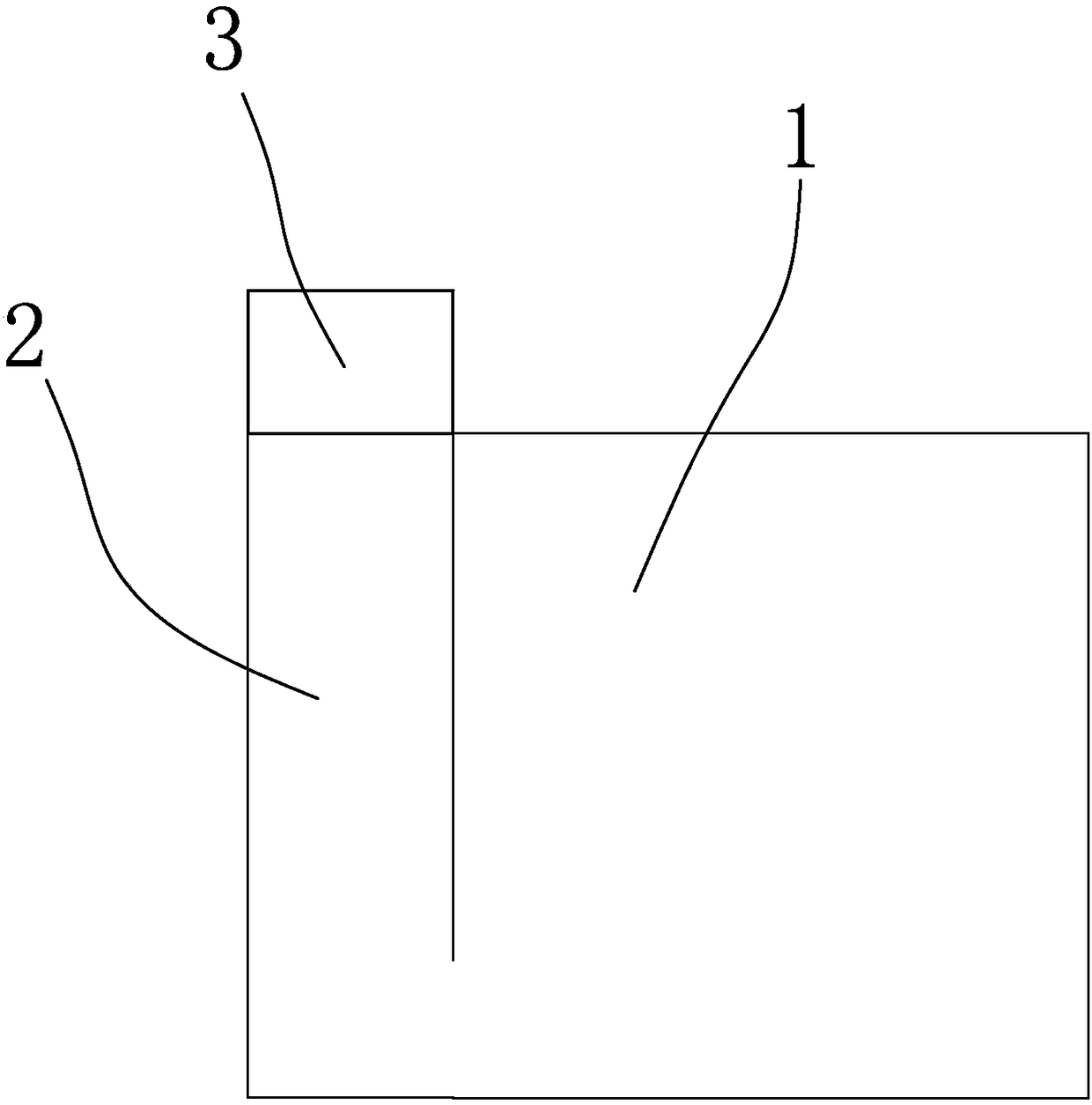

[0022] refer to Figure 1 to Figure 2 An embodiment of the surface treatment process of an aluminum alloy mold of the present invention will be further described.

[0023] combine figure 1 , a kind of aluminum alloy mold surface treatment process, comprises the following steps: (1) material selection: select 6061T aluminum alloy material for use, its composition and each composition content are: copper Cu:0.15~0.4, manganese Mn:0.15, magnesium Mg: 0.8~1.2, zinc Zn: 0.25, chromium Cr: 0.04~0.35, titanium Ti: 0.15, silicon Si: 0.4~0.8, iron Fe: 0.7, and the rest content is Al. In order to cooperate with the processing method of the present invention, it has Good forming effect of aluminum oxide layer;

[0024] (2) Molding: forming aluminum alloy molds through blanking, spot welding assembly and hydraulic forming processes;

[0025] (3) Surface treatment: Aluminum oxide coating is deposited on the surface of aluminum alloy mold by anodic oxidation method of aluminum alloy mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com