Layer by layer self-assembling anti-flaming cotton fabric and preparation method thereof

A technology of layer-by-layer self-assembly and flame-retardant cotton, which is applied in the field of flame-retardant cotton fabrics to achieve the effect of high phosphorus content and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

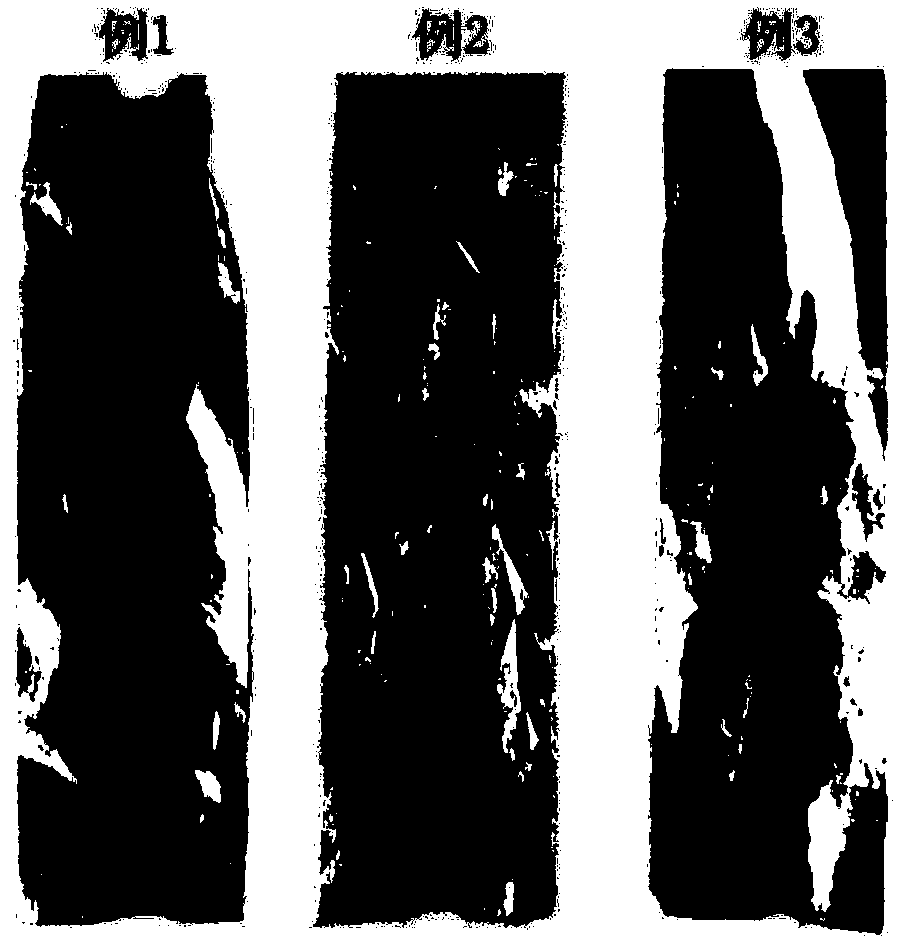

Image

Examples

Embodiment 1

[0029] A layer-by-layer self-assembled flame-retardant cotton fabric, the preparation method of which is:

[0030] (1) Preparation of polycation sol

[0031] Dissolve poly(3-chloropropyltriethoxysiloxane) in DMF, add cyanuric acid and triethylamine, heat and stir, after the reaction is completed, cool to precipitate triethylamine hydrochloride, filter with suction Remove triethylamine hydrochloride;

[0032] Then add trimethylamine aqueous solution to the reaction solution, after the reaction is completed, remove the solvent and wash to obtain polycation sol, namely PCQS; poly(3-chloropropyl triethoxysiloxane), cyanuric acid, tris The molar ratio of ethylamine to trimethylamine aqueous solution is 2:1:1:2.

[0033] (2) Preparation of anion solution

[0034] PA was dissolved in deionized water, and its pH was adjusted with sodium hydroxide solution to make a 2wt% anion solution.

[0035] (3) Cotton fabric pretreatment

[0036] Soak the scoured cotton fabric in 1wt% polyeth...

Embodiment 2

[0041] A layer-by-layer self-assembled flame-retardant cotton fabric, the preparation method of which is:

[0042] (1) Preparation of polycation sol

[0043] Dissolve poly(3-chloropropyltriethoxysiloxane) in DMF, add cyanuric acid and triethylamine, heat and stir, after the reaction is completed, cool to precipitate triethylamine hydrochloride, filter with suction Remove triethylamine hydrochloride;

[0044] Then add trimethylamine aqueous solution to the reaction solution, after the reaction is completed, remove the solvent and wash to obtain polycation sol, namely PCQS; poly(3-chloropropyl triethoxysiloxane), cyanuric acid, tris The molar ratio of ethylamine to trimethylamine aqueous solution is 2:1:1:2.

[0045] (2) Preparation of anion solution

[0046] PA was dissolved in deionized water, and its pH was adjusted with sodium hydroxide solution to make a 2wt% anion solution.

[0047] (3) Cotton fabric pretreatment

[0048] Soak the scoured cotton fabric in 1wt% polyeth...

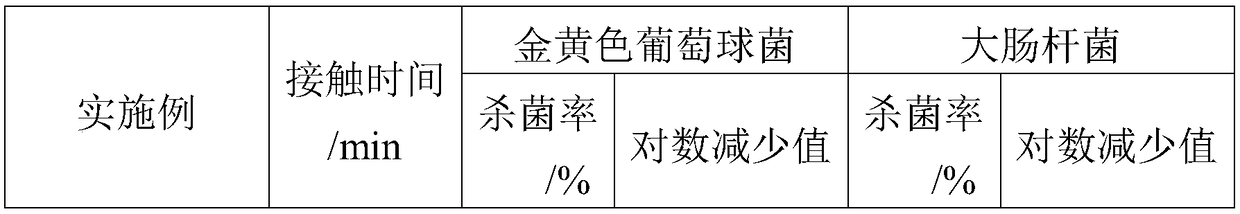

Embodiment 3

[0053] A layer-by-layer self-assembled flame-retardant cotton fabric, the preparation method of which is:

[0054] (1) Preparation of polycation sol

[0055] Dissolve poly(3-chloropropyltriethoxysiloxane) in DMF, add cyanuric acid and triethylamine, heat and stir, after the reaction is completed, cool to precipitate triethylamine hydrochloride, filter with suction Remove triethylamine hydrochloride;

[0056]Then add trimethylamine aqueous solution to the reaction solution, after the reaction is completed, remove the solvent and wash to obtain polycation sol, namely PCQS; poly(3-chloropropyl triethoxysiloxane), cyanuric acid, tris The molar ratio of ethylamine to trimethylamine aqueous solution is 2:1:1:2.

[0057] (2) Preparation of anion solution

[0058] PA was dissolved in deionized water, and its pH was adjusted with sodium hydroxide solution to make a 2wt% anion solution.

[0059] (3) Cotton fabric pretreatment

[0060] Soak the scoured cotton fabric in 1wt% polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com