Pretreatment, modification and dyeing one-bath one-step processing method for cotton fabric

A processing method and fabric technology, applied in the field of dyeing and finishing, can solve the problems of not meeting the requirements of energy saving and emission reduction, high water and energy consumption, and high production cost, and achieve the effects of excellent dyeing fastness, improved production efficiency, and simple and feasible process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

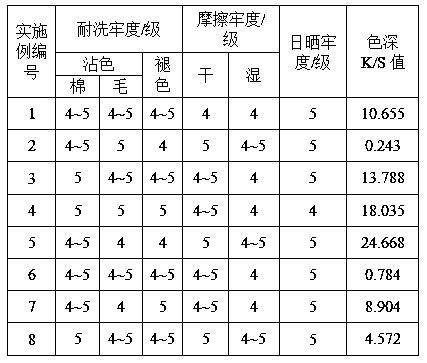

Examples

Embodiment 1

[0019] A one-bath one-step processing method for pretreatment, modification and dyeing of cotton woven fabrics, the steps are as follows:

[0020] Prepare 5 g / L sodium hydroxide, 8 g / L refining agent (6 g / L sodium dodecylbenzene sulfonate, 2 g / L flat plus O), 10 g / L hydrogen peroxide, 6 g / L stabilizer sodium silicate , 4 g / L cationic modifier WLS and 5 g / L Argazol yellow NF-GR, the cotton woven fabric was put into the above treatment liquid according to the bath ratio of 1:4, under the condition of continuous ultrasonic at 40 ℃ Raise the temperature to 100°C at a rate of 3°C / min, keep it warm for 60 minutes, then cool down to 50°C at a rate of 3°C / min, take out the fabric and wash it with water, neutralize acid, soap, wash with water, and dry.

Embodiment 2

[0022] A one-bath one-step processing method for pretreatment, modification and dyeing of cotton woven fabrics, the steps are as follows:

[0023] Prepare 0.5 g / L potassium hydroxide, 10 g / L refining agent (7 g / L sodium dodecyl sulfonate, 3 g / L flat plus O), 3 g / L hydrogen peroxide, 2 g / L stabilizer sodium phytate A treatment solution consisting of 10 g / L cationic modifier PECH-amine and 0.2 g / L Argazol red NF-3B was put into the above treatment solution according to the bath ratio of 1:40 for cotton woven fabrics. Raise the temperature at 40°C, raise the temperature to 80°C at a rate of 0.4°C / min, keep it warm for 100 minutes, then cool down to 60°C at a rate of 3°C / min, take out the fabric and wash it with water, acid neutralization, soaping, water washing, and drying.

Embodiment 3

[0025] A one-bath one-step processing method for pretreatment, modification and dyeing of cotton woven fabrics, characterized in that:

[0026] Prepare 20 g / L sodium carbonate, 2 g / L refining agent (1.5 g / L fatty acid methyl ester ethoxylate sodium sulfonate, 0.5 g / L lauryl polyoxyethylene polyoxypropylene block polyether), 20 g / L Hydrogen peroxide, 10 g / L stabilizer sodium pyrophosphate, 15 g / L modifier LY-60 and 7 g / L Argazol emerald green NF-2G were used to treat cotton woven fabrics at a bath ratio of 1:20. In the above-mentioned treatment solution, under continuous ultrasonic conditions, the temperature was raised to 40°C, raised to 85°C at a rate of 0.9°C / min, kept at a temperature of 20 minutes, and then cooled to 40°C at a rate of 3°C / min, and the fabric was taken out to be fully washed with water and acid neutralized. , soaping, washing, drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com