A graphene-supported porous vanadium dioxide microsphere composite material and a preparation method thereof

A technology of vanadium dioxide and composite materials, applied in the field of electrochemistry, can solve the problems of low experimental conditions, hinder development, unsatisfactory capacity and cycle stability, etc., achieve simple preparation process, alleviate structural degradation, improve structural stability and Effects of Electron Conduction Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a graphene-supported porous vanadium dioxide microsphere, the method steps are as follows:

[0038] 1) Add 116.98 mg of NH to 25 mL of deionized water 4 VO 3 powder, stir and disperse;

[0039] 2) 0.5 mL of HCl (1M) was added dropwise to the dispersion obtained in step 1), and stirred until dissolved;

[0040] 3) 1.5 mL of hydrazine hydrate was added dropwise to the solution obtained in step 2), and stirred for 30 min;

[0041] 4) dropwise adding graphene oxide aqueous solution (the amount of graphene oxide is 11 mg) to the suspension obtained in step 3), after stirring and dispersing, freeze-drying for 24 h to obtain a precursor;

[0042]5) The precursor obtained in step 4) is calcined at 450° C. for 2 h at a heating rate of 2° C. / min in a nitrogen atmosphere to obtain a graphene-supported porous vanadium dioxide microsphere composite material.

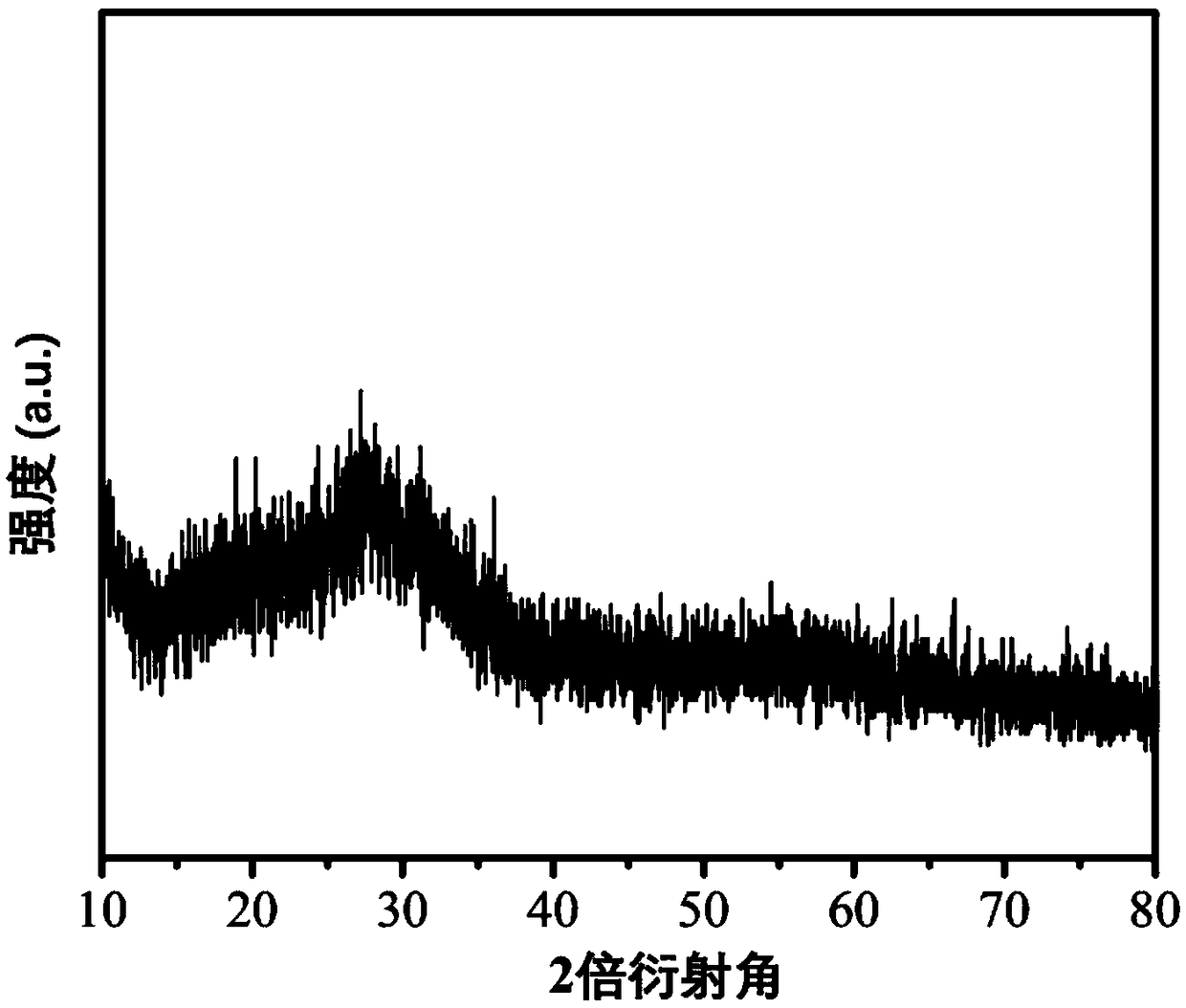

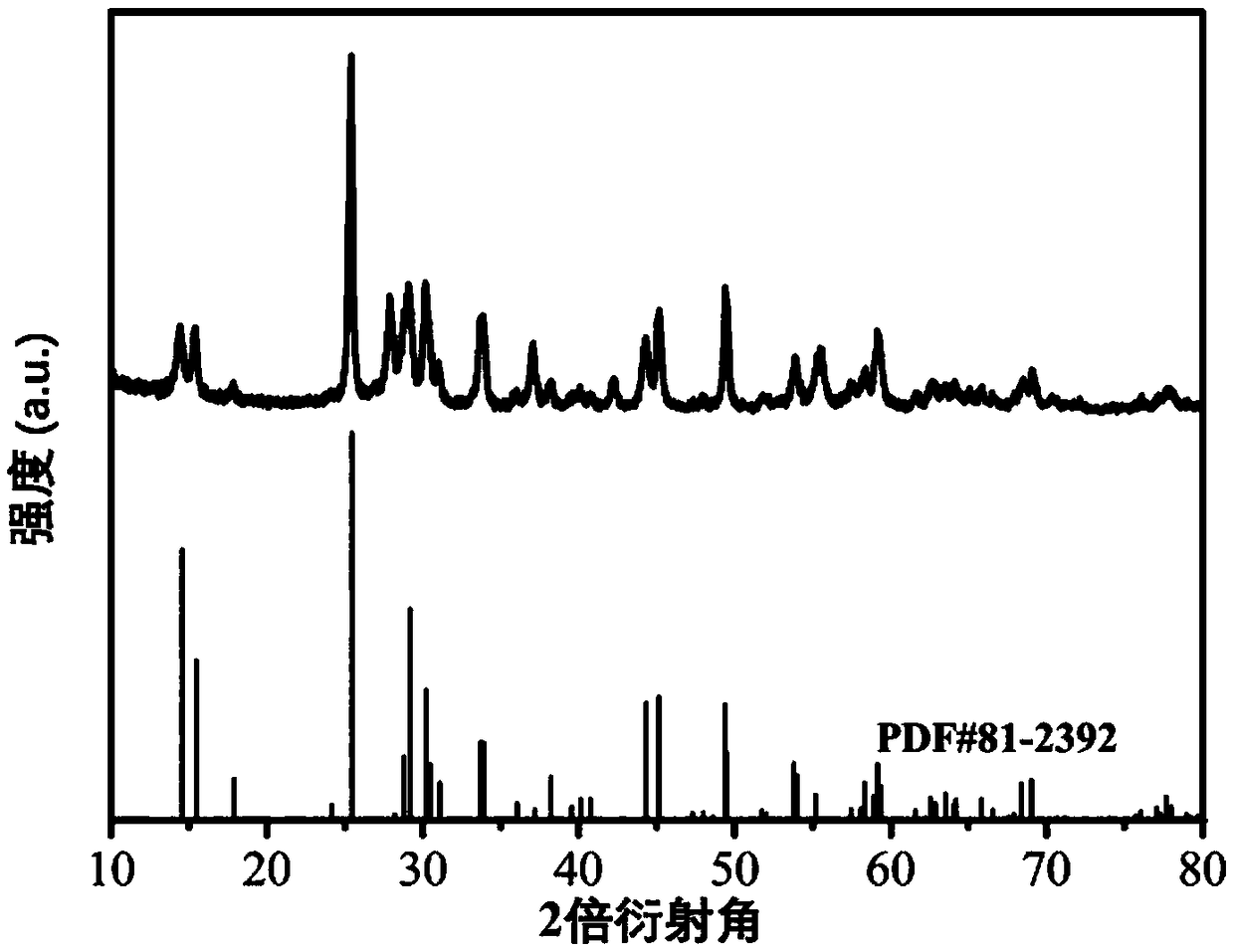

[0043] The XRD results of the precursor are as follows figure 1 As shown, the crystallinity of t...

Embodiment 2

[0053] 1) Add 93 mg of NH to 25 mL of deionized water 4 VO 3 powder, stir and disperse to obtain a dispersion;

[0054] 2) 0.4 mL of HCl (1M) was added dropwise to the dispersion obtained in step 1), and stirred until dissolved;

[0055] 3) 1.2 mL of hydrazine hydrate was added dropwise to the solution obtained in step 2), and stirred for 20 min to obtain a suspension;

[0056] 4) dropwise add graphene oxide aqueous solution (the amount of graphene oxide is 6 mg) to the suspension obtained in step 3), stir and disperse and freeze-dry for 24h to obtain a precursor;

[0057] 5) The precursor obtained in step 4) is calcined at 400° C. for 4 hours at a heating rate of 3° C. / min in a nitrogen atmosphere to obtain a graphene-supported porous vanadium dioxide microsphere composite material.

[0058] The XRD results of the precursor show that the crystallinity of the precursor is poor, and no obvious diffraction peaks are detected, indicating that it mainly presents an amorphous st...

Embodiment 3

[0066] 1) Add 140mg NH to 25mL deionized water 4 VO 3 powder, stir and disperse to obtain a dispersion;

[0067] 2) 0.6 mL of HCl (1M) was added dropwise to the dispersion obtained in step 1), and stirred until dissolved;

[0068] 3) 1.8 mL of hydrazine hydrate was added dropwise to the solution obtained in step 2), and stirred for 30 min to obtain a suspension;

[0069] 4) dropwise adding graphene oxide aqueous solution (the amount of graphene oxide is 16mg) to the suspension obtained in step 3), after stirring and dispersing, freeze-drying for 24h to obtain a precursor;

[0070] 5) The precursor obtained in step 4) is calcined at 500° C. for 1 h at a heating rate of 1.5° C. / min in a nitrogen atmosphere to obtain a graphene-supported porous vanadium dioxide microsphere composite material.

[0071] The XRD results of the precursor show that the crystallinity of the precursor is poor, and no obvious diffraction peaks are detected, indicating that it mainly presents an amorph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com