A method for preparing a honeycomb lithium sulfide battery positive electrode material by a template method

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve problems such as difficult to control volume expansion, uneven distribution of carbon-sulfur, etc., achieve volume expansion elimination, high dispersion uniformity, The effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

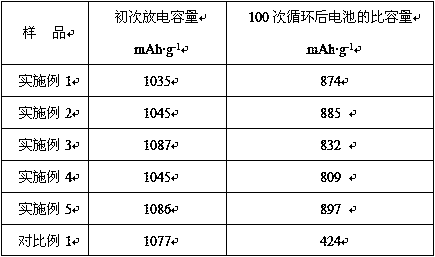

Examples

Embodiment 1

[0029] (1) Weigh 8 parts by mass of tetraethyl orthosilicate, 0.4 parts by mass of butanol, 15 parts by mass of sodium sulfide, 45 parts by mass of polytetrafluoroethylene emulsion containing carbon nanotubes and appropriate amount of deionized water, pH Control the aqueous solution of hydrochloric acid and hydrofluoric acid at 2.0;

[0030](2) Mix the dilute acid solution and the dispersant into the reaction vessel, control the concentration of the dispersant to 0.04mol / L, stir evenly, raise the temperature to 62°C, and dissolve ethyl orthosilicate at 1.5-2 Add it dropwise into the reactor within 1 hour to obtain the reaction precursor solution, then raise the temperature of the reaction precursor solution to 70°C, keep it warm for 1.6 hours, then cool it down to 25°C, shake the test tube forward and backward for 180 seconds, discharge the material for later use, and obtain a particle size of 30 μm, porosity 55%, mesopore average pore diameter 180nm monodisperse hollow mesopo...

Embodiment 2

[0034] (1) Weigh 5 parts by mass of tetraethyl orthosilicate, 0.5 parts by mass of butyl acetate as a dispersant, 12 parts by mass of sodium sulfide, 69 parts by mass of polytetrafluoroethylene emulsion containing carbon nanotubes and an appropriate amount of deionized Water, pH value controlled at 2.0 aqueous solution of glacial acetic acid and hydrofluoric acid;

[0035] (2) Mix the dilute acid solution and the dispersant into the reaction vessel, control the concentration of the dispersant to 0.09mol / L, stir evenly, raise the temperature to 60°C, and dissolve ethyl orthosilicate within 1.7 hours Add it dropwise into the reactor to obtain the reaction precursor solution, then raise the temperature of the reaction precursor solution to 70°C, keep it warm for 3 hours, then lower the temperature to 20°C, shake the test tube forward and backward for 350 seconds, discharge the material for later use, and obtain a particle size of 10 μm. The porosity is 75%, and the average pore s...

Embodiment 3

[0039] (1) Weigh 8 parts by mass of tetraethyl orthosilicate, 0.1 parts by mass of ether as a dispersant, 17 parts by mass of sodium sulfide, 60 parts by mass of polytetrafluoroethylene emulsion containing carbon nanotubes and an appropriate amount of deionized water, The pH value is controlled at 3.0 in aqueous solution of hydrochloric acid and hydrofluoric acid;

[0040] (2) Mix the dilute acid solution and the dispersant into the reaction vessel, control the concentration of the dispersant to 0.07mol / L, stir evenly, raise the temperature to 60°C, and dissolve ethyl orthosilicate within 1.7 hours Add it dropwise into the reactor to obtain the reaction precursor solution, then raise the temperature of the reaction precursor solution to 71°C, keep it warm for 2 hours, then cool it down to 25°C, shake the test tube forward and backward for 200 seconds, discharge the material for later use, and obtain a particle size of 35 μm. The porosity is 65%, and the average pore size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com