A processing method of a wearable antenna

A processing method and antenna technology, applied in the field of antennas, can solve the problems of low antenna radiation efficiency, short circuit or open circuit of copper foil tape, poor adhesion, etc., and achieve the effect of low antenna performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The form of wearable antenna selected in this embodiment is the form of planar monopole antenna. In order to ensure wearing comfort, this embodiment uses polyester-cotton blended woven fabric as the medium base material. After measurement, its equivalent relative permittivity is 2.0 and its thickness is 0.256mm. In order to reduce the Joule loss of the antenna, this embodiment uses silver paste with high conductivity as the conductive material. In order to realize the manufacture of wearable antenna accurately and conveniently, this embodiment adopts coplanar waveguide as the feeding mode of wearable antenna, so that the pattern of the whole wearable antenna is only printed on one side, and the required polyester-cotton blended woven fabric is only layer.

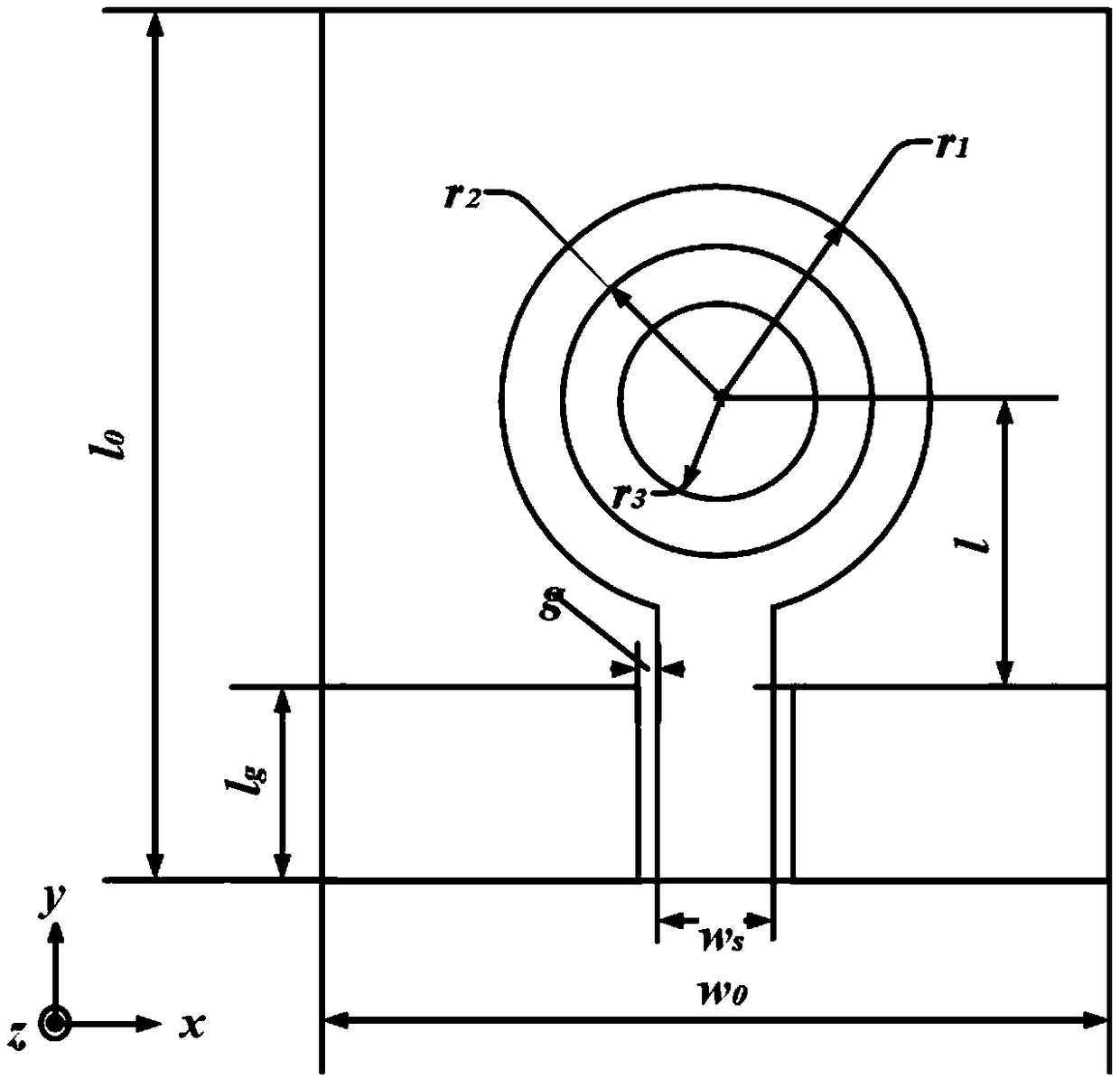

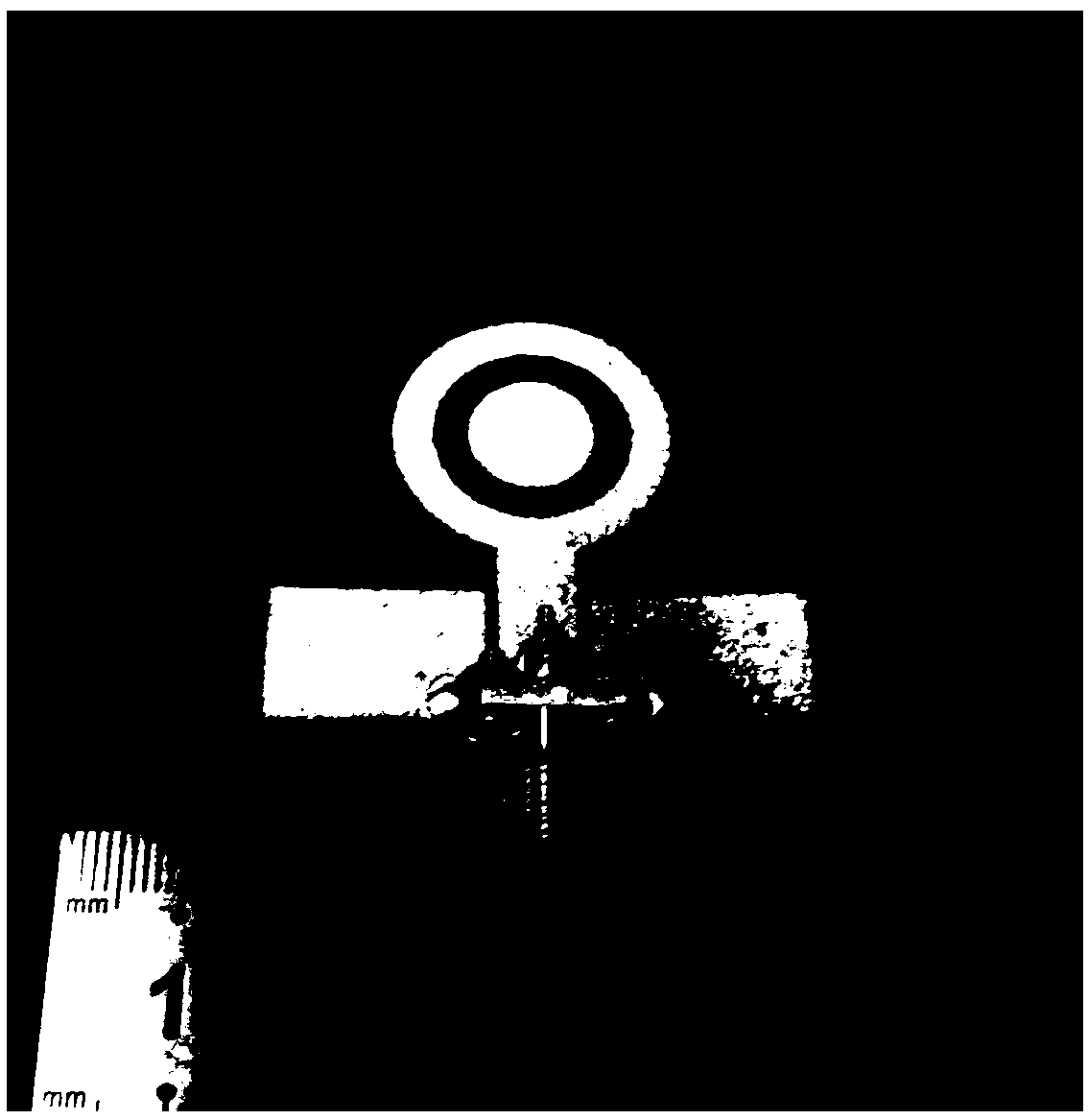

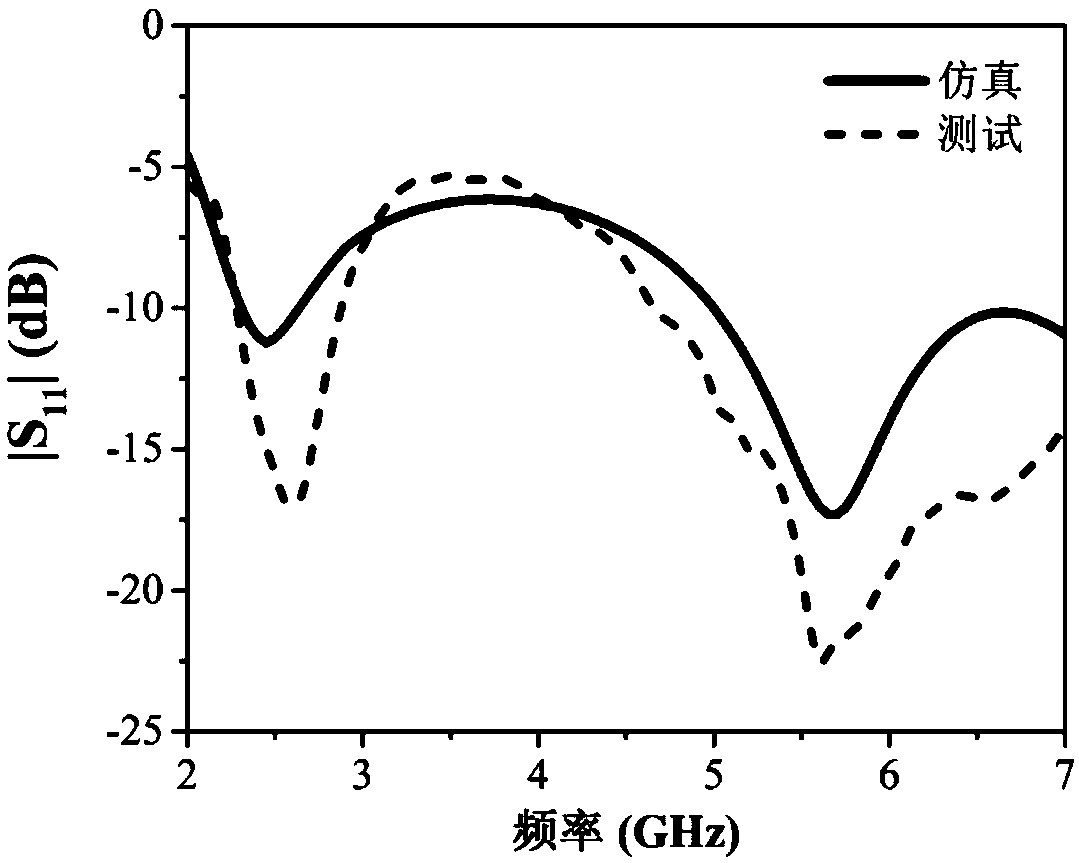

[0029] The equivalent relative permittivity and thickness of the selected polyester-cotton blended woven fabric are used for simulation modeling of wearable antennas. In this embodiment, a dual-frequency planar mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com