A vanadium nitride nanocluster loaded on a 3D carbon foam skeleton and its preparation method

A technology of vanadium nitride nano and carbon foam, which is applied in the direction of carbon preparation/purification, chemical instruments and methods, nitrogen compounds, etc., can solve the problems of large energy consumption, high cost, and complicated operation, and achieve uniform distribution and stable structure , solve the effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

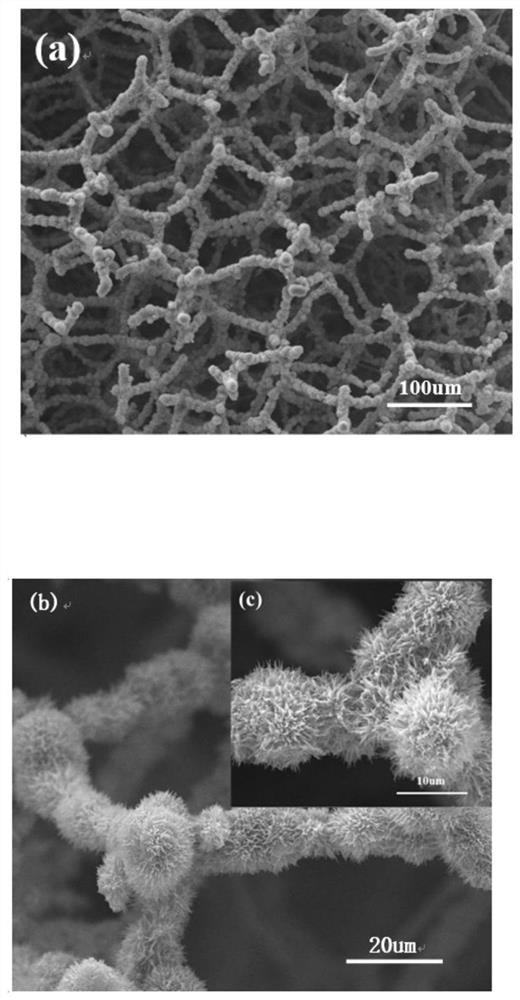

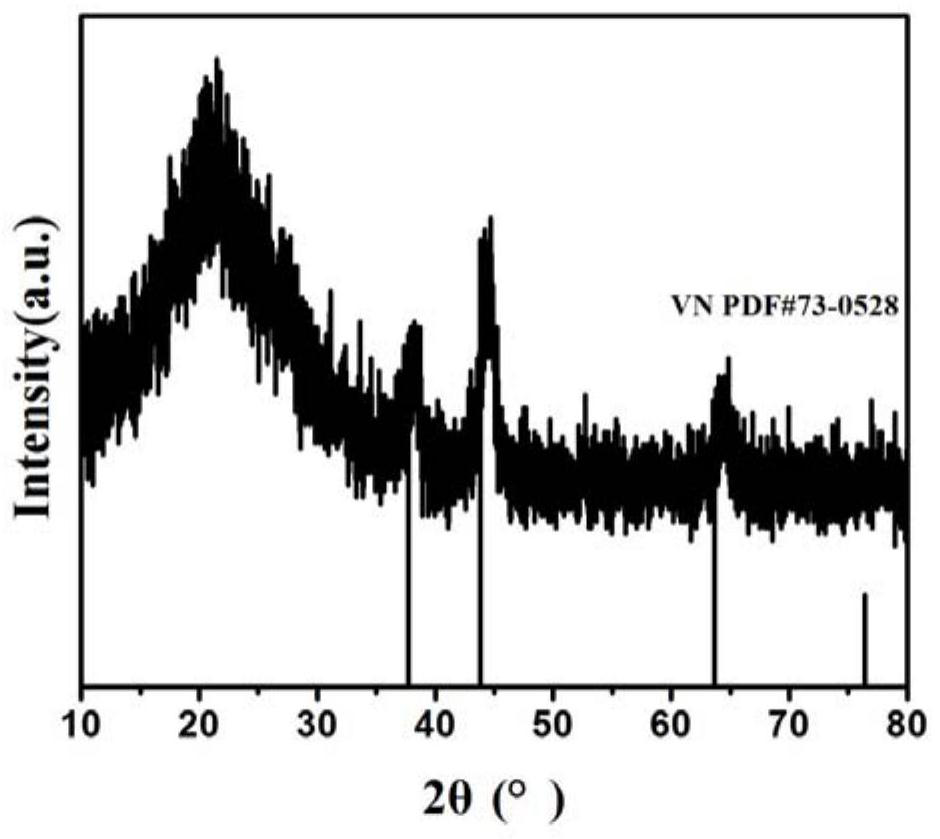

[0022] A method for preparing vanadium nitride nanoclusters loaded on a 3D carbon foam skeleton provided by the invention comprises the following steps:

[0023] In the first step, the melamine foam was placed in a tube furnace and heated at 5 °C min under an argon or nitrogen atmosphere. -1 After calcining at 800°C for 1 hour, and cooling to room temperature, a 3D carbon foam is obtained;

[0024] The second step is to configure an aqueous oxalic acid solution with a pH of 1 to 4;

[0025] The 3rd step, the concentration is the ammonium metavanadate of 10~30mol / L and the hexamethylenetetramine of 1~10mol / L and above-mentioned oxalic acid aqueous solution with (1~3):(1~4):(1 ~5) volume ratio mixed, fully stirred to obtain solution A;

[0026] The fourth step is to vacuum-impregnate the carbon foam in the first step in solution A and transfer it to a polytetrafluoroethylene reactor, and seal it, and at the same time, hydrothermally react at a temperature of 100°C to 150°C for...

Embodiment 1

[0029] In the first step, the melamine foam was placed in a tube furnace and heated at 5 °C min under an argon or nitrogen atmosphere. -1 After calcining at 800°C for 1 hour, and cooling to room temperature, a 3D carbon foam is obtained;

[0030] The second step is to configure an aqueous oxalic acid solution with a pH of 1;

[0031] In the third step, mix the ammonium metavanadate with a concentration of 10 mol / L, the hexamethylenetetramine of 1 mol / L and the above-mentioned oxalic acid aqueous solution in a volume ratio of 1:1:1, and stir fully to obtain solution A;

[0032] The fourth step is to vacuum impregnate the carbon foam in solution A and transfer it to a polytetrafluoroethylene reactor, and seal it. At the same time, it is hydrothermally reacted at a temperature of 100°C for 0.5h, and then it is washed and freeze-dried. get intermediate products;

[0033] The fifth step is to put the intermediate product obtained above into a tube furnace, and under an ammonia at...

Embodiment 2

[0037] In the first step, the melamine foam was placed in a tube furnace and heated at 5 °C min under an argon or nitrogen atmosphere. -1 After calcining at 800°C for 1 hour, and cooling to room temperature, a 3D carbon foam is obtained;

[0038] The second step is to configure an aqueous oxalic acid solution with a pH of 2;

[0039] The third step is to mix the ammonium metavanadate with a concentration of 20mol / L, the hexamethylenetetramine of 5mol / L and the above-mentioned oxalic acid aqueous solution in a volume ratio of 2:3:3, and stir fully to obtain solution A;

[0040] The fourth step is to vacuum impregnate the carbon foam in solution A and transfer it to a polytetrafluoroethylene reactor, and seal it. At the same time, it is hydrothermally reacted at a temperature of 150 ° C for 8 hours, and then it is washed and freeze-dried to obtain mid product;

[0041] The fifth step is to put the intermediate product obtained above into a tube furnace, and under an ammonia at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com