A hybrid cross-linked dynamic polymer

A hybrid cross-linking, polymer technology, applied in the field of smart polymers, can solve the problems of performance and application limitations, covalent interpenetrating network cannot be repaired, lack of dynamics, etc. various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

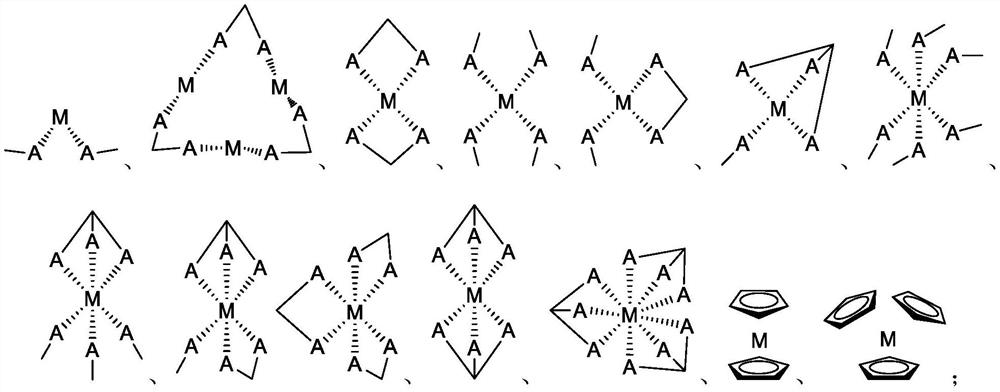

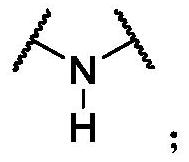

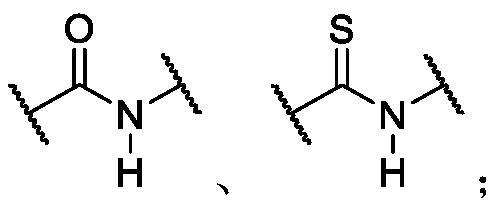

Method used

Image

Examples

preparation example Construction

[0145] In the preparation process of dynamic polymer, three methods are mainly used to foam dynamic polymer: mechanical foaming method, physical foaming method and chemical foaming method.

[0146] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer by vigorous stirring in the preparation process of the dynamic polymer to make it into a uniform foam, and then through physical Or chemical changes make it gel and form into foam. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0147]Wherein, the described physical foaming method utilizes physical principles to realize the foaming of the polymer in the preparation process of the dynamic polymer, which generally includes but is not limited to the following methods: (1) the inert gas foaming method, that is, in the Press the inert gas into the molten polymer or paste materia...

Embodiment 1

[0205] Pyridine-3,5-dicarboxylic acid was dissolved in dichloromethane, and then a certain amount of thionyl chloride was added, and the reaction was refluxed at 70 °C, so that the two carboxylic acid chlorides of pyridine-3,5-dicarboxylic acid were dissolved. and finally remove the resulting impurities to obtain pyridine-3,5-diacid chloride. Mix propane-1,2,3-triol and a certain amount of pyridine-3,5-diacyl chloride, use triethylamine as a catalyst, and react in dichloromethane to control the number of moles of hydroxyl groups and the number of moles of acid chloride groups in the reaction The ratio is about 3:2, and the polycondensation reaction is carried out to obtain polymer 1 with a pyridine group in the backbone and a hydroxyl group in the side group. Weigh the reaction material component A in parts by weight: 10 parts of polymer 1, 0.2 part of chain extender 2,2-bis(hydroxymethyl)propionic acid, 0.2 part of dibutyltin dilaurate, 0.2 part of triethylenedicarbonate Ami...

Embodiment 2

[0207]

[0208] 100 g of amino-terminated silicone oil and 200 mL of dry dichloromethane were added to reactor No. 1, and stirred for 2 h at room temperature under nitrogen atmosphere; 4.08 g of pyridine dicarbonyl chloride and 20 mL of dry dichloromethane were added to No. Chloromethane was stirred at room temperature under nitrogen atmosphere for 2 h for use. The solution in Reactor No. 2 was mixed with the solution in Reactor No. 1 under an ice bath at 0°C, stirred for 2 h, moved to room temperature, and stirred for 48 h to obtain polymer 2. 5 parts of polymer 2 and 6 parts of TDI were added to the No. 3 reactor according to parts by weight, and the prepolymer polymer 2' was formed after high-speed stirring. Weigh the reaction material component A in parts by weight: 7 parts of polymer 2', 0.1 part of dibutyltin dilaurate, 0.1 part of 2-(aminomethyl)-2-methyl-1,3-propanediamine, 0.1 part of silicone oil, 5 parts of dichloromethane, 3 parts of water, and 0.5 part of ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com