Single-component self-crosslinking waterborne polyurethane flame-retardant dispersion liquid as well as preparation method and application thereof

A water-based polyurethane and self-crosslinking technology, applied in the field of polyurethane, can solve the problems of emitting smoke, casualties, and the lack of self-extinguishing properties of one-component polyurethane coatings, achieving strong adhesion, long service life, and easy industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

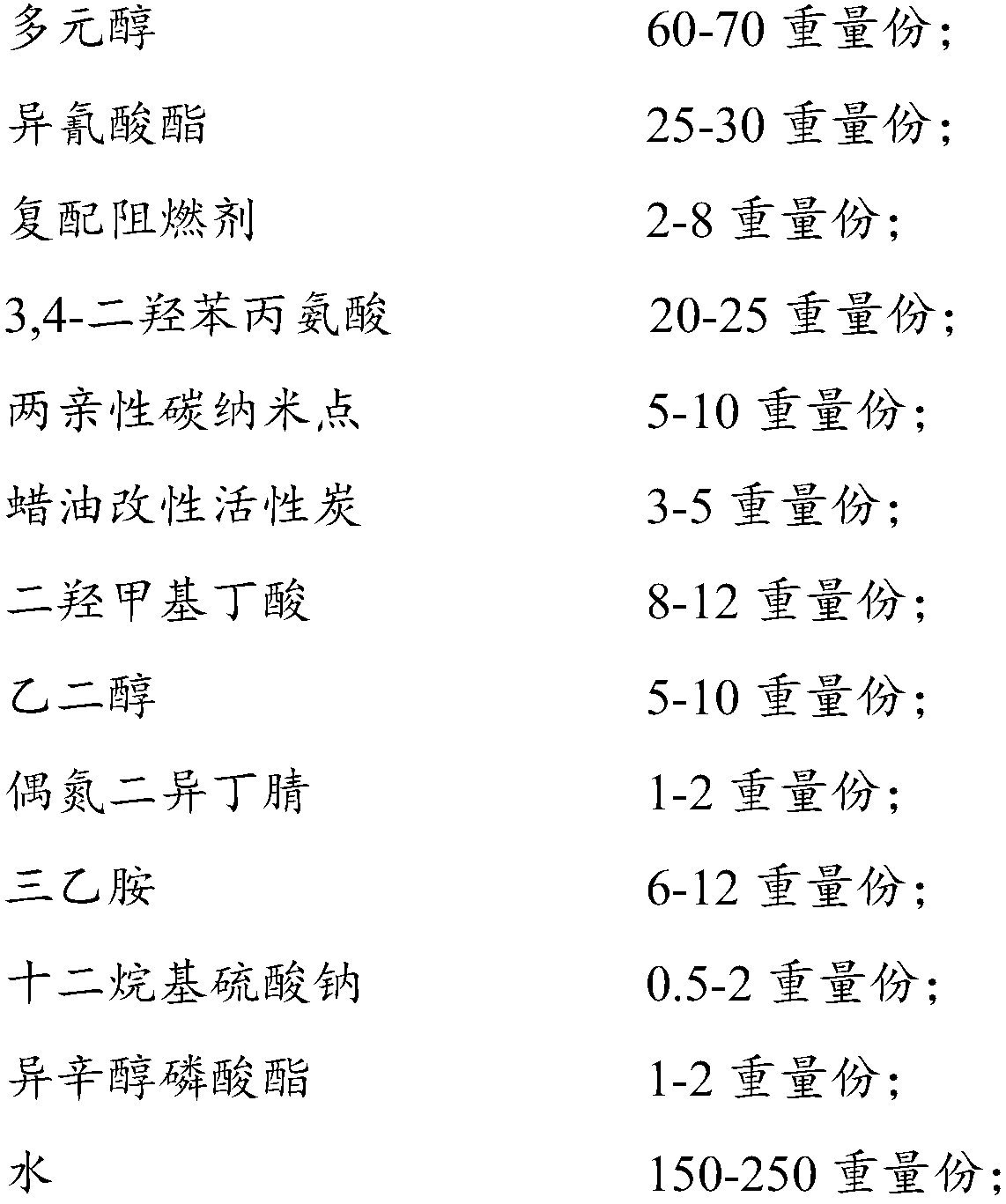

[0033] One-component self-crosslinking water-based polyurethane flame retardant dispersion, consisting of 60 parts by weight of polyethylene adipate diol, 25 parts by weight of TDI, 3 parts by weight of compound flame retardant, 20 parts by weight of 3,4- Dihydroxyphenylalanine, 5 parts by weight of amphiphilic carbon nanodots, 3 parts by weight of wax oil modified activated carbon, 8 parts by weight of dimethylol butyric acid, 5 parts by weight of ethylene glycol, 1 part by weight of azodiiso Nitrile, 7.5 parts by weight of triethylamine, 0.5 part by weight of sodium lauryl sulfate, 1 part by weight of isooctyl phosphate and 150 parts by weight of water;

[0034] Wherein, the preparation method of wax oil modified activated carbon is as follows: 5g activated carbon is submerged in 10mL wax oil, ultrasonically dispersed uniformly, static for 5 minutes, filtered, the sediment is centrifugally deoiled, and air-dried;

[0035] The compound flame retardant is a mixture of zinc bor...

Embodiment 2

[0043] One-component self-crosslinking water-based polyurethane flame retardant dispersion, composed of 65 parts by weight of polybutylene adipate diol, 28 parts by weight of XDI, 6 parts by weight of compound flame retardant, 22 parts by weight of 3,4- Dihydroxyphenylalanine, 8 parts by weight of amphiphilic carbon nanodots, 4 parts by weight of wax oil modified activated carbon, 10 parts by weight of dimethylol butyric acid, 7 parts by weight of ethylene glycol, 1.5 parts by weight of azodiiso Butyronitrile, 9 parts by weight of triethylamine, 1 part by weight of sodium lauryl sulfate, 1.5 parts by weight of isooctyl phosphate and 180 parts by weight of water;

[0044] Wherein, the preparation method of wax oil modified activated carbon is as follows: 5g activated carbon is submerged in 10mL wax oil, ultrasonically dispersed uniformly, static for 5 minutes, filtered, the sediment is centrifugally deoiled, and air-dried;

[0045] The compound flame retardant is a mixture of z...

Embodiment 3

[0053] One-component self-crosslinking water-based polyurethane flame retardant dispersion, which is composed of 70 parts by weight of polyethylene glycol, 30 parts by weight of IPDI, 8 parts by weight of compound flame retardant, 25 parts by weight of 3,4-dihydroxyphenylalanine, 10 parts by weight of amphiphilic carbon nanodots, 5 parts by weight of wax oil modified activated carbon, 12 parts by weight of dimethylol butyric acid, 10 parts by weight of ethylene glycol, 2 parts by weight of azobisisobutyronitrile, 12 parts by weight of Ethylamine, 2 parts by weight of sodium lauryl sulfate, 2 parts by weight of isooctyl phosphate and 250 parts by weight of water;

[0054] Wherein, the preparation method of wax oil modified activated carbon is as follows: 5g activated carbon is submerged in 10mL wax oil, ultrasonically dispersed uniformly, static for 5 minutes, filtered, the sediment is centrifugally deoiled, and air-dried;

[0055] The compound flame retardant is a mixture of z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com