A capillary monolithic column for separation of benzene homologues and preparation method thereof

A technology of capillary monolithic columns and homologues, which is applied in the fields of analytical chemistry and environmental analysis, can solve problems such as difficult and efficient use of MOFs materials, and achieve good stability and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

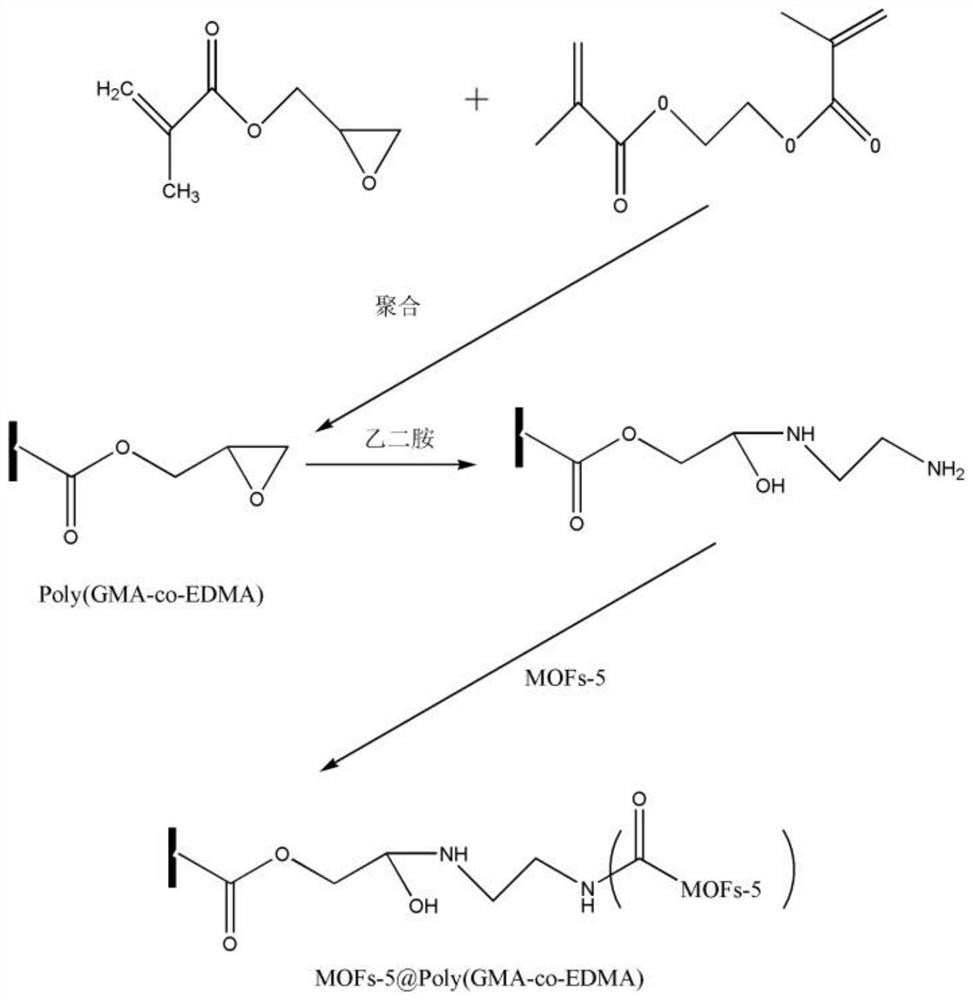

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of a capillary monolithic column for the separation of benzene homologues

[0024] 1. Synthesis of MOF-5:

[0025] 1. Using the classic hot solvent method, a certain amount of Zn(NO 3 ) 2 ·6H 2 O and H 2 BDC (terephthalic acid) is mixed, dissolved in an appropriate amount of DMF, shaken vigorously for 30 minutes and placed in a high-temperature and high-pressure reactor. After reacting at 120°C for 24 hours, the product was suction-filtered and washed three times with DMF, each time 15 mL, to remove unreacted reactants. Use CH again 2 Cl 2 (dichloromethane) for one day to remove the DMF in the guest molecule. Finally, the prepared MOF-5 was vacuum-dried at 120°C for 24 hours to obtain a white solid, which was characterized by XRD, SEM, and infrared.

[0026] Table 1 raw material consumption

[0027]

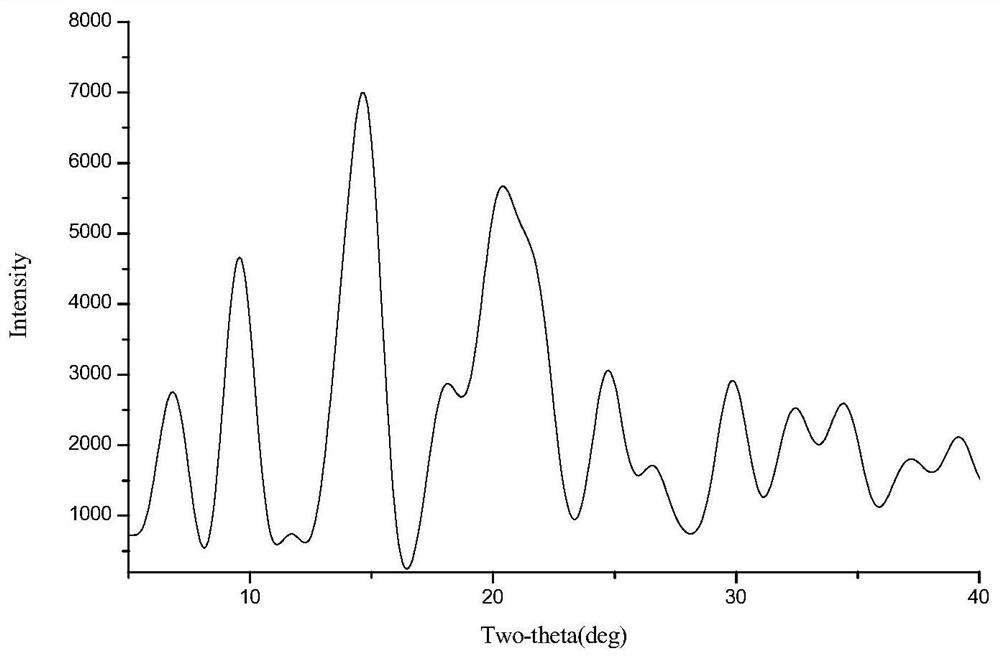

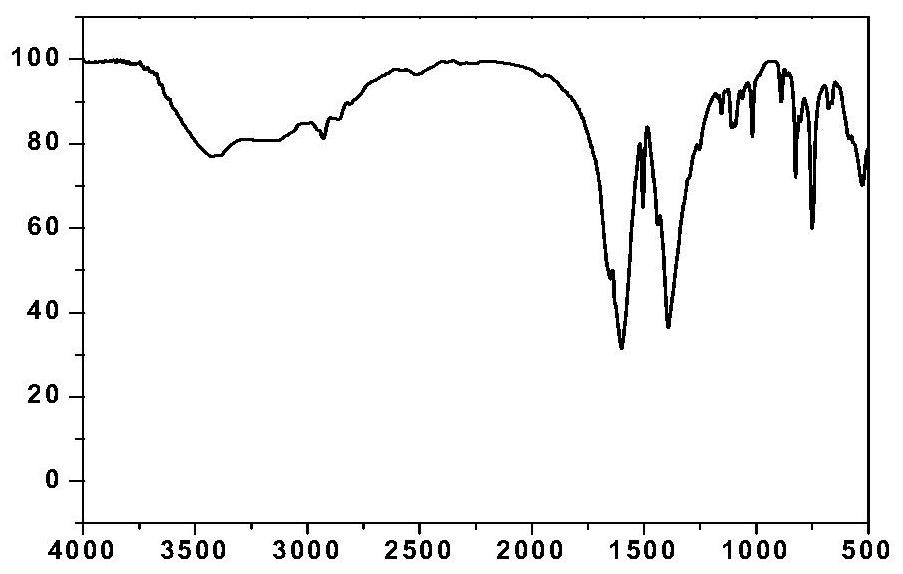

[0028] 2. The XRD spectrum of the prepared MOF-5 material is as follows figure 2 shown. It can be seen from the figure that the charac...

experiment example 1

[0044] Experimental example 1 Stability analysis of a capillary monolithic column used for separation of benzene homologues

[0045] When methanol is used as the mobile phase, the flow rate is from 0.02mL·min -1 to 0.06mL·min -1 There is a nice linear relationship between back pressure and flow rate, indicating that the permeability does not change with flow rate as in Image 6 shown. When water is used as the mobile phase, the flow rate and back pressure also have a linear relationship and the R value reaches 0.99. Figure 7 shown. Bring the data into the permeability formula to calculate the permeability K as the following table:

[0046] Table 4-Physical data of each substance

[0047]

experiment example 2

[0048] Experimental example 2 detects the separation effect of homologues of benzene

[0049] 1. Connect the monolithic capillary column MOF-5@ploy(GMA-co-EDMA) (experimental group) and monolithic capillary column poly(GMA-co-EDMA) (control group) to HPLC (FL2200) respectively. The mobile phase was 75% methanol / 25% water, and the ultraviolet spectrum was used as the detector, and the flow rate was 0.02mL·min-1. Take 10 microliters each of 1% toluene (methanol:toluene=99:1, v / v), 1% benzene (methanol:benzene=99:1, v / v), 0.5% phenol (MeOH:Phenol=199: 1, v / v) Shake well in a centrifuge tube. Inject 20 μL of the mixed solution with a sampler and detect it with a 245nm ultraviolet detector.

[0050] 2. If Figure 8 As shown, the GMA-EDMA monolithic column without immobilized MOF-5 (control group) did not have any separation ability for the mixed solution, and only one peak appeared.

[0051] 3. If Figure 9 As shown, the monolithic column (experimental group) of immobilized MO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com