A preparation method of Raney nickel-iron catalyst and its application in the decolorization method of dye wastewater

A technology for iron catalyst and dye wastewater, applied in the direction of catalyst activation/preparation, Raney-type catalysts, chemical instruments and methods, etc., can solve the problems of high specific surface area, unstable activity, affecting treatment effect, etc., and achieve simple preparation method, The effect of improving the decolorization treatment rate and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the preparation method of Raney nickel-iron catalyst is as follows:

[0023] (1) Slowly add 20ml of NaOH with a concentration of 6mol / L to 2g of Raney nickel-aluminum alloy powder that has been crushed through a 120-mesh sieve. N 2 protection, wash to neutrality after the reaction, and then wash with absolute ethanol for 3 to 5 times to obtain the treated Raney nickel powder;

[0024] (2) add Fe in the Raney nickel powder 1g that step (1) obtains 2+ Concentration is 0.43mmol / L ferrous sulfate solution 20ml, obtains mixed solution;

[0025] (3) Configure 0.8mol / L NaBH 4 25ml of the solution was added dropwise into the above mixture, and the reaction was continued for about 15 minutes under ultrasonic waves to obtain a Raney nickel-iron catalyst.

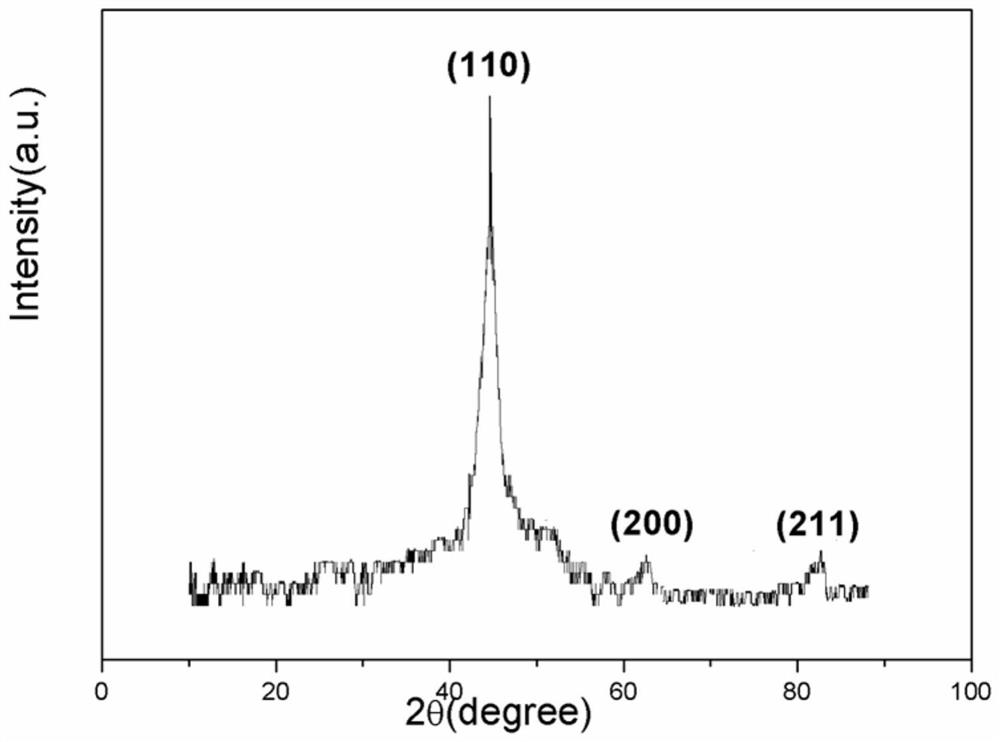

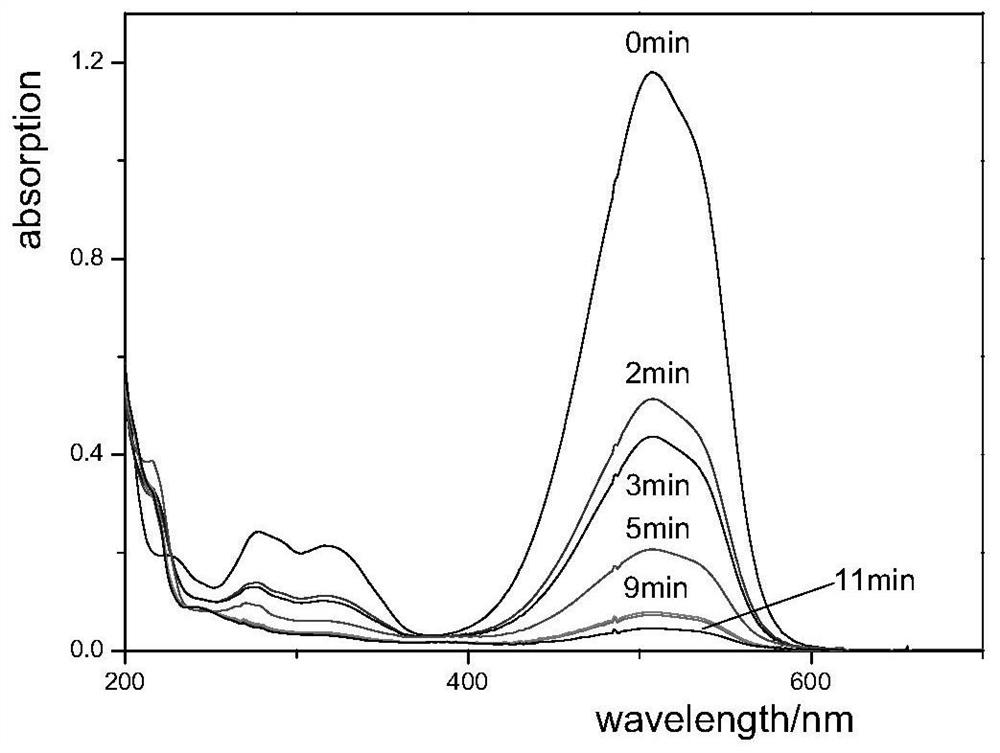

[0026] The accurate ratio of the prepared Raney nickel-iron catalyst was measured by atomic absorption, and the loading ratio of Fe was 40%. Catalyst X-ray diffraction characterization spectrum as shown in f...

example 2

[0033] Example 2: The preparation method of Raney nickel-iron catalyst is as follows:

[0034] (1) Slowly add 20ml of NaOH with a concentration of 6mol / L to 2g of Raney nickel-aluminum alloy powder that has been crushed through a 120-mesh sieve. N 2 protection, wash to neutrality after the reaction, and then wash with absolute ethanol for 3 to 5 times to obtain the treated Raney nickel powder;

[0035] (2) add Fe in the Raney nickel powder 2g that step (1) obtains 2+ Concentration is 0.43mmol / L ferrous sulfate solution 20ml, obtains mixed solution;

[0036] (3) Configure 0.8mol / L NaBH 4 25ml of the solution was added dropwise into the above mixture, and the reaction was continued for about 15 minutes under ultrasonic waves to obtain a Raney nickel-iron catalyst.

[0037] The accurate proportion of the prepared Raney nickel-iron catalyst was measured by atomic absorption, and the loading ratio of Fe was 20%.

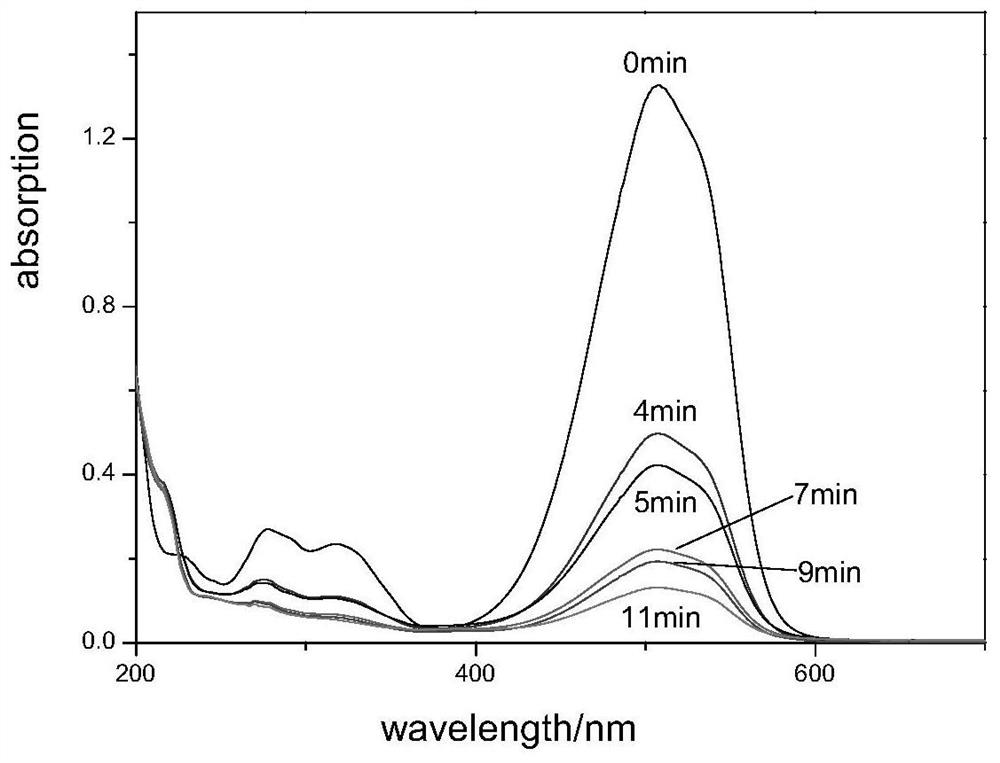

[0038] Under the environment of pH=1.3, add the Raney nickel-ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com