Preparation method and application of visible light response magnetic metal organic framework material

A metal-organic framework and magnetic metal technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, light water/sewage treatment, etc., to achieve energy saving, high magnetic properties, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

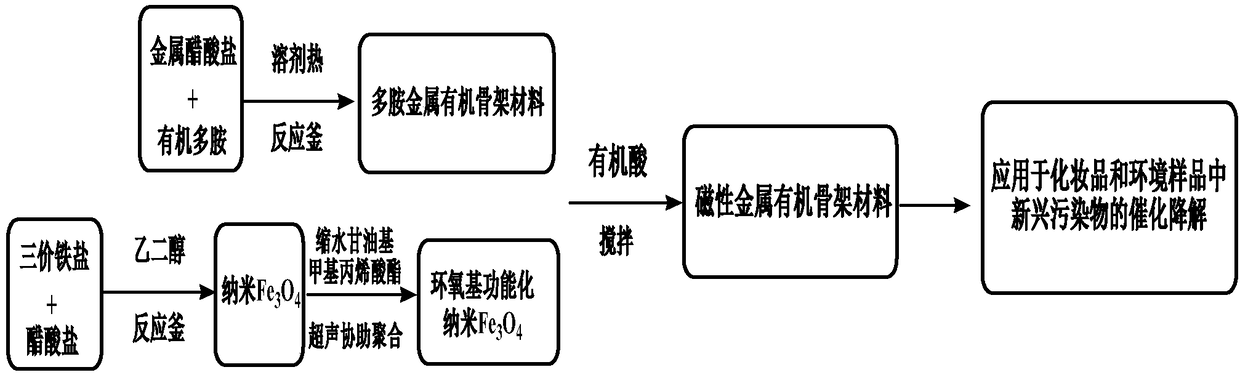

Method used

Image

Examples

Embodiment 1

[0057] Weigh Cu(Ac) 2 Dissolve 0.5g each of tetraethylenepentamine and tetraethylenepentamine in 10mL ethanol, and stir at room temperature for 10min to form a stable orange solution. The reaction solution was transferred to the reactor, and reacted at 180°C for 8h. After cooling, it was centrifuged, washed with deionized water and ethanol three times each, until the pH value was 7, and vacuum-dried at 60°C for 12 hours to obtain the polyamine metal-organic framework material.

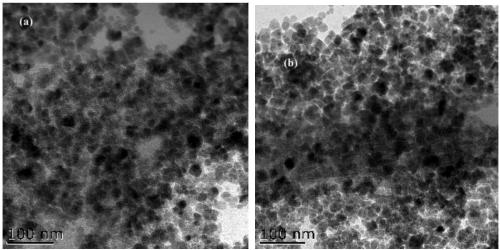

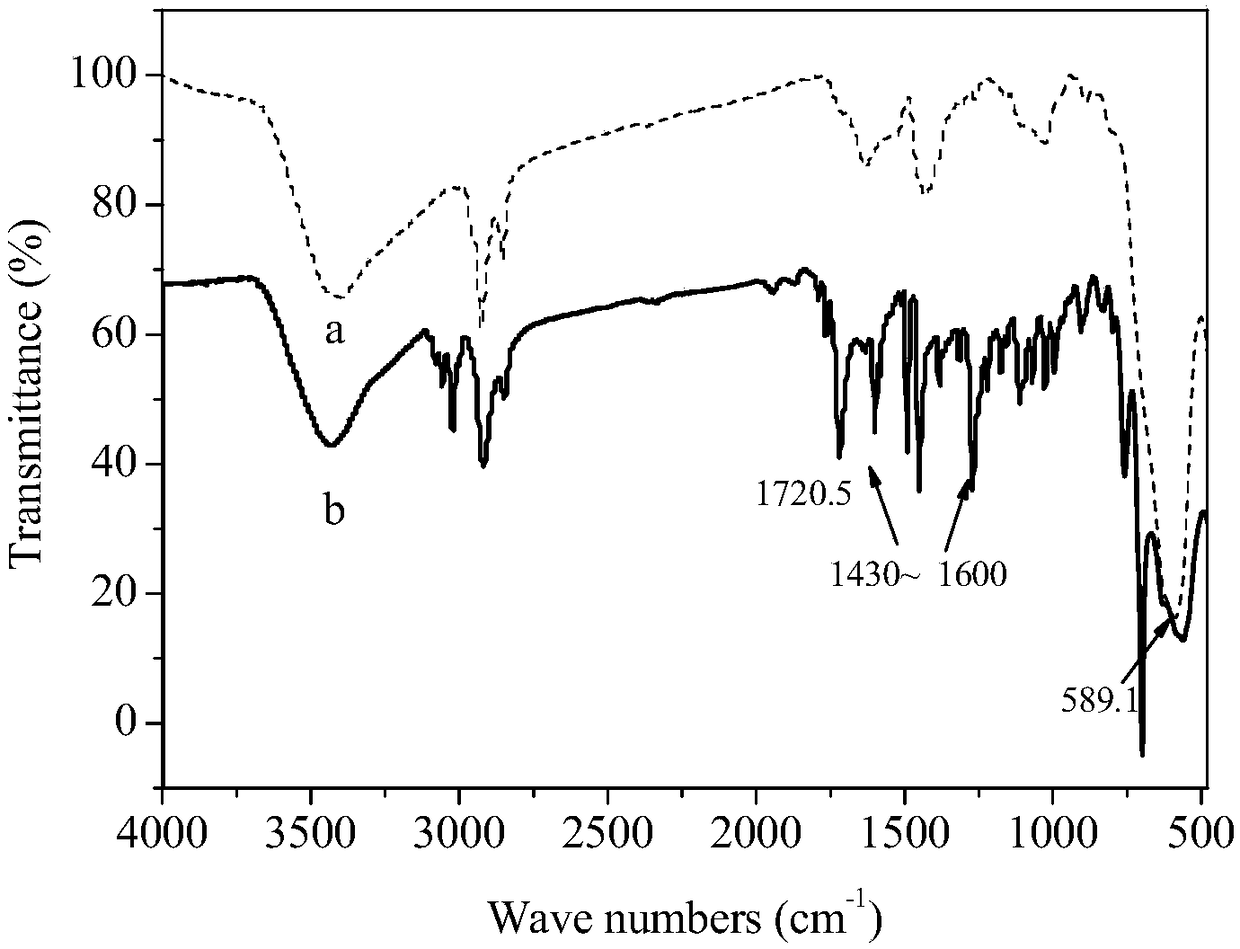

[0058] Weigh 4g FeCl respectively 3 ·6H 2 O and 12g of anhydrous sodium acetate were dissolved in 100mL of ethylene glycol, stirred at room temperature for 10min, and stirred until a stable orange solution was formed. The reaction solution was transferred to a reaction kettle, and reacted at 180°C for 8h. After cooling, it was magnetically separated, washed with deionized water and ethanol three times each, until the pH value was 7, and vacuum-dried at 60°C for 12h to obtain nano-Fe 3 o 4 . Furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com