Integrated treatment equipment for rural aquaculture sewage with high-concentration COD (Chemical Oxygen Demand) and ammonia nitrogen

A technology for aquaculture sewage and treatment equipment, which is applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc. Low cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

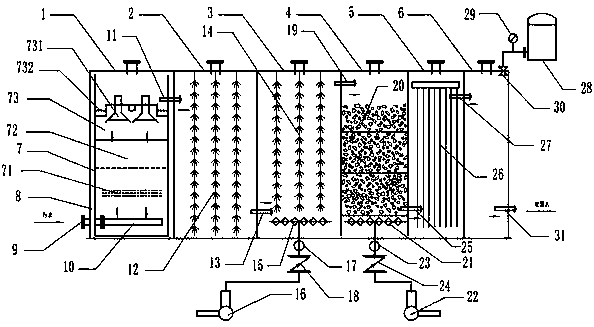

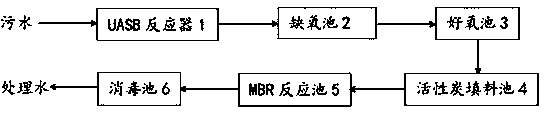

[0026] Such as figure 1 , figure 2 As shown, a kind of rural high concentration COD of the present invention, ammonia-nitrogen farming wastewater integrated treatment equipment, comprises UASB reactor 1, anoxic pool 2, aerobic pool 3, activated carbon packing pool 4, MBR reaction pool 5 and disinfection pool 6, UASB reactor 1 is provided with a reaction zone 7 inside, a water storage zone 8 is provided outside the reaction zone 7, a sludge settlement zone 71 is provided at the lower part of the reaction zone 7, and a suspended sludge is provided above the sludge settlement zone 71 Zone 72, a separation zone 73 is provided above the suspended sludge zone 72, a three-phase separator 731 is provided on the upper part of the separation zone 73, overflow weirs 732 communicated with the water storage zone 8 are provided on both sides of the separation zone 73, UASB reactor The lower part of the reactor 1 is provided with a sewage inlet 9, which communicates with the sewage input p...

Embodiment 2

[0035] The technological process of embodiment 1 is as follows:

[0036] According to the embodiment of Example 1, the specific implementation process of the present invention: the sewage first enters the UASB reactor 1, and in the UASB reactor 1, about 60% of COD is removed, and the macromolecular organic matter that is difficult to degrade is decomposed into a simple molecular structure , Molecular structure with better biochemical properties. In UASB reactor 1, the residence time of sewage is about 16 hours, and the generated methane (CH4) gas overflows through the three-phase separator 731, and the generated sludge sinks, while the initial treatment The final sewage is discharged through the overflow weir 732 and enters the anoxic pool 2; the first packing 12 is housed in the anoxic pool 2, and the first packing 12 provides a place for microbial growth, and the microbes hang a film on the surface of the first packing 12, increasing Biomass, sewage in the anoxic pool 2 for ...

Embodiment 3

[0038] The effect of aquaculture sewage treatment in embodiment 2 is as follows:

[0039] Sewage treatment plan:

[0040] The treated water volume is 20 tons / day, the influent water quality is shown in Table 1, and the effluent water quality is shown in Table 2.

[0041] Table 1 Influent water quality indicators

[0042] monitoring project

COD

BOD5

SS

NH3-N

TP

pH

Data (mg / L)

300

160

200

35

3

7.2

[0043] Table 2 Outlet water quality indicators

[0044] Test items

COD

BOD5

SS

NH3-N

TP

pH

Data (mg / L)

≤50

≤10

≤10

≤5(8)

≤0.5(1)

6~9

[0045] As can be seen from the data in Table 1 and Table 2, the treated water after being treated by a kind of rural high-concentration COD and ammonia nitrogen farming sewage integrated treatment equipment of the present invention, the water quality meets one of the standards in GB18918-2002 "Urban Wastewater Treatment Plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com