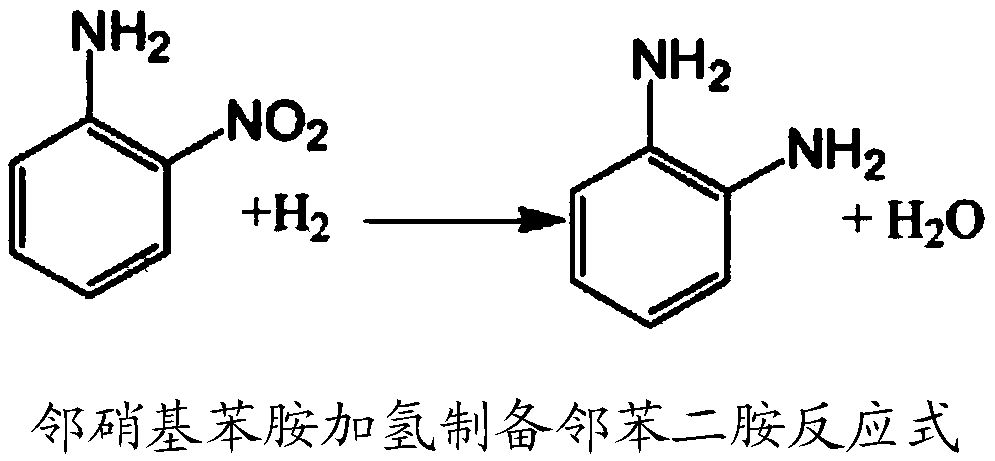

Method for preparing o-phenylenediamine by utilizing catalytic reduction of ortho-nitroaniline

A technology of o-nitroaniline and o-phenylenediamine, which is applied in the preparation of o-phenylenediamine and in the field of organic synthesis, can solve the problems of inability to be recycled for a long time, high initial activity, loss, etc., and achieves difficult deactivation and good maintenance , The effect of catalyst stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of embodiment 1 Pd-Ni bimetallic catalyst (Pd-Ni / GO)

[0020] 50ml of deionized water, 0.5ml of 0.02mol / L PdCl 2 , 0.5ml of 0.02mol / L NiCl 2 , 0.8g graphene oxide, after ultrasonication at 160W for 30min at room temperature, 2ml hydrazine hydrate was added dropwise, continued ultrasonication at 160W, 60°C for 1h, centrifugation, washing with deionized water 3 times, centrifugation, and vacuum drying to obtain Pd-Ni / GO.

Embodiment 2

[0021] The preparation of embodiment 2 other catalysts

[0022] According to the method of Example 1, adjust different metal salts, such as using ferric chloride instead of nickel chloride to obtain Pd-Fe / GO, copper chloride instead of nickel chloride to obtain Pd-Cu / GO, and cobalt chloride instead of chloride Nickel can obtain Pd-Co / GO, chloroplatinic acid can replace palladium chloride to obtain Pt-Ni / GO, chloroauric acid can obtain Au-Ni / GO, and sequentially prepare Pt-Fe / GO, Pt-Cu / GO, Pt-Co / GO, Au-Cu / GO, Au-Co / GO. Wherein it involves the catalyst preparation of iron, the reducing agent adopts ascorbic acid, and the dosage is 0.4g.

Embodiment 3

[0023] Embodiment 3 contrast catalyst and blank catalyst

[0024] At the same time, only a single metal salt can be used to obtain Pd / GO, Pt / GO, Au / GO, Cu / GO, Co / GO, Ni / GO, and without using any metal, a blank catalyst, that is, a reduced GO catalyst support can be obtained . The dosage of a single salt is 1ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com