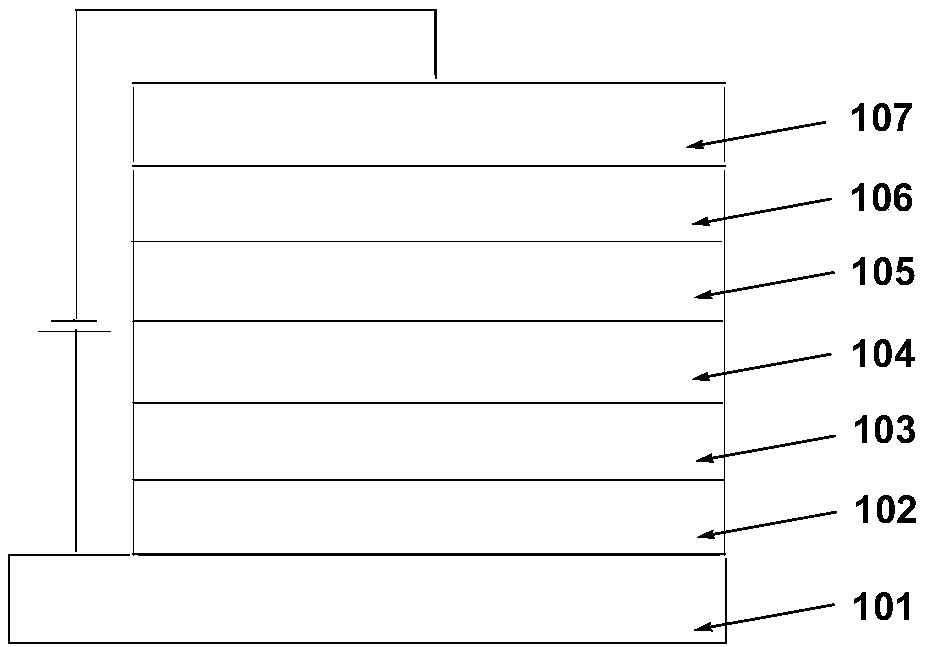

OLED (Organic Light Emitting Diode) material and application thereof

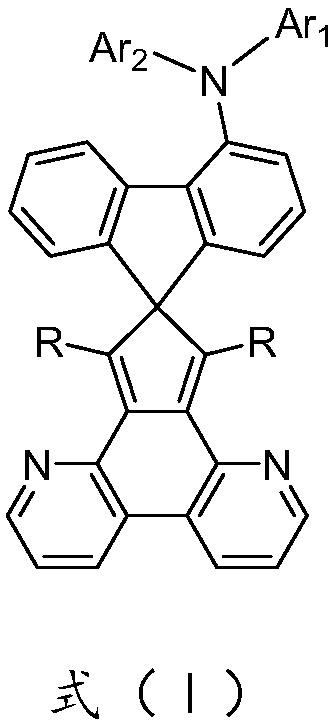

A technology selected from phenyl and phenyl, which is applied in the field of small-molecule OLED materials, can solve problems such as difficult to meet the needs of use, and achieve the effect of excellent molecular quality and improved device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

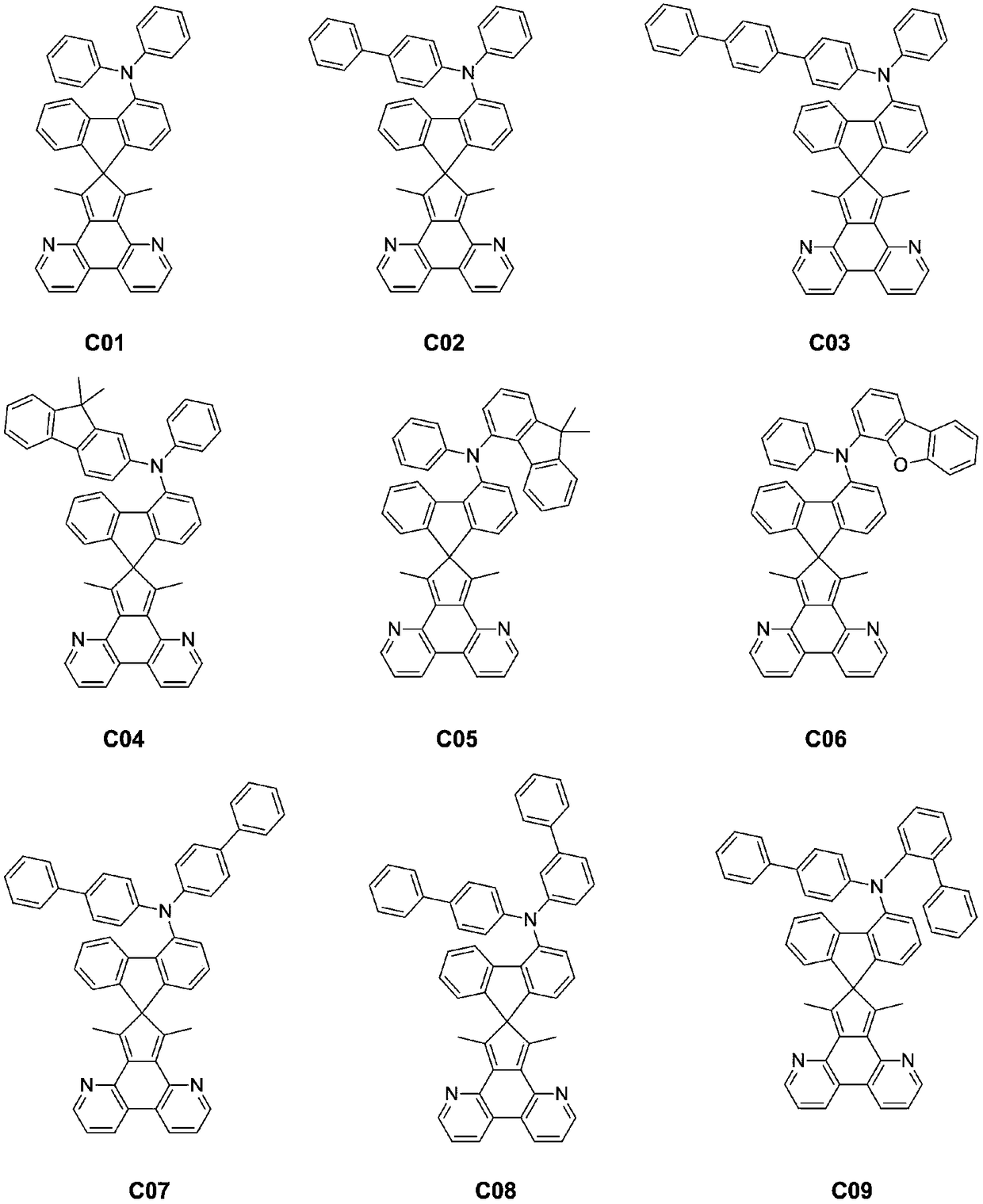

Examples

Embodiment 1

[0027] The preparation of embodiment 1 intermediate D01

[0028]

[0029] Using compound A01 (CAS-RN: 84-12-8) and compound B01 as raw materials, the intermediate D01 was prepared by referring to the method described in the literature (DOI: 10.1021 / ol502418k), and 42.7 g of the target product was obtained. High-resolution mass spectrum, positive ion mode , formula C 17 h 12 N 2 O, theoretical value 260.0950, test value 260.0957.

Embodiment 2

[0030] The preparation of embodiment 2 intermediate D02

[0031]

[0032] Using compound A01 and compound B02 as raw materials, the intermediate D02 was prepared according to the method described in the literature (DOI: 10.1021 / ol502418k), and 37.4 g of the target product was obtained. High-resolution mass spectrometry, positive ion mode, molecular formula C 27 h 16 N 2 O, theoretical value 384.1263, test value 384.1258.

Embodiment 3

[0033] The preparation of embodiment 3 intermediate F01

[0034]

[0035] In a 1000mL three-necked flask, add 2,2'-dibromo-1,1'-biphenyl (46.8g, 0.15mol), tetrahydrofuran (330g), under nitrogen protection, cool down to -85°C, add n-butyl Lithium n-hexane solution (2.5mol / L, 60mL, 0.15mol), 1 hour dropwise addition is completed, insulation 0.5 hour, the compound D01 (39.1g, 0.15mol) prepared in the embodiment 1 is dissolved in 220g tetrahydrofuran, then Slowly drop it into the above-mentioned 1000mL three-neck bottle, control the temperature to be less than -75°C, complete the dropwise addition in 1.5 hours, keep it warm for 2 hours, move the three-necked bottle into a water bath at 25°C, naturally raise the temperature to 5°C, and drop in a mass concentration of 5 % dilute hydrochloric acid 120g, stirred for 0.5 hours, separated, collected the organic phase, and removed the solvent to obtain 82.2g of the crude product of compound E01, which was directly put into the next st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com