A kind of preparation method of water-based system superamphiphobic durable coating

A super-amphiphobic durable, water-based system technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of organic solvent pollution recovery, inconvenience, poor durability of super-amphiphobic coatings, etc., to achieve easy large-scale production, simple and easy process The effect of running and painting fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

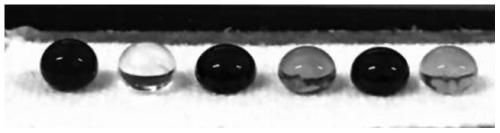

[0029] In this embodiment, the base material is cotton cloth, and the preparation method of coating superamphiphobic coating on cotton cloth is carried out as follows:

[0030] (1) Cleaning the surface of the cotton cloth to obtain a treated base material.

[0031] (2) in PVDF emulsion (10g, solid content is 14%, and particle diameter is 220nm), add heptadecafluorodecyltriethoxysilane (2g), surfactant Zonyl 321 (3g, DuPont company product) carry out 0.5 After 1 hour of stirring and mixing, 50 grams of water was added and stirred evenly (stirring time was 1 hour), and a composite modified emulsion of polymer particles was obtained.

[0032] (3) Immerse the surface of the substrate obtained in (1) into the polymer particle modified emulsion obtained in (2) for 5 minutes, dry at room temperature for 10 minutes, and then put the substrate in a 130 ° oven for drying heat treatment In 1 hour, a durable superamphiphobic coating with a thickness of 700 nm can be obtained.

[0033] S...

Embodiment 2

[0043] In this embodiment, filter paper is selected as the base material, and the preparation method of coating superamphiphobic coating on the filter paper is carried out as follows:

[0044] (1) cleaning the surface of the filter paper to obtain a processed base material;

[0045] (2) in PVDF emulsion (10g, solid content is 14%, and particle diameter is 220nm), add heptadecafluorodecyltriethoxysilane (2g), surfactant Zonyl 321 (3g, DuPont company product) carry out 0.5 After 1 hour of stirring and mixing, 50 grams of water was added and stirred evenly (stirring time was 1 hour), and a composite modified emulsion of polymer particles was obtained.

[0046] (3) Spray the polymer particle modified emulsion obtained in (2) onto the substrate surface obtained in (1) for 5 minutes, dry at room temperature for 10 minutes, and then put the substrate in a 130 ° oven for drying heat treatment 1 Durable superamphiphobic coatings with a thickness of 700 nm can be obtained within hours....

Embodiment 3

[0053] In this embodiment, the substrate material is wood, and the coating preparation method of coating super amphiphobic on wood is carried out as follows:

[0054] (1) cleaning the wood surface to obtain a good base material;

[0055] (2) in PVDF emulsion (10g, solid content is 14%, and particle diameter is 220nm), add heptadecafluorodecyltriethoxysilane (2g), surfactant Zonyl 321 (3g, DuPont company product) carry out 0.5 After 1 hour of stirring and mixing, 50 grams of water was added and stirred evenly (stirring time was 1 hour), and a composite modified emulsion of polymer particles was obtained.

[0056] (3) Spray the polymer particle modified emulsion obtained in (2) onto the substrate surface obtained in (1) for 5 minutes, dry at room temperature for 10 minutes, and then put the substrate in a 130 ° oven for drying heat treatment 1 Durable superamphiphobic coatings with a thickness of 700 nm can be obtained within hours.

[0057] Simultaneously, the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com