Acetic bacteria and application thereof

A technology of acetic acid bacteria and vinegar, which is applied in the field of microbial application and food brewing, can solve the problem of unretrieved acetic acid bacteria, and achieve the effect of improving utilization rate, improving economic benefits, and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

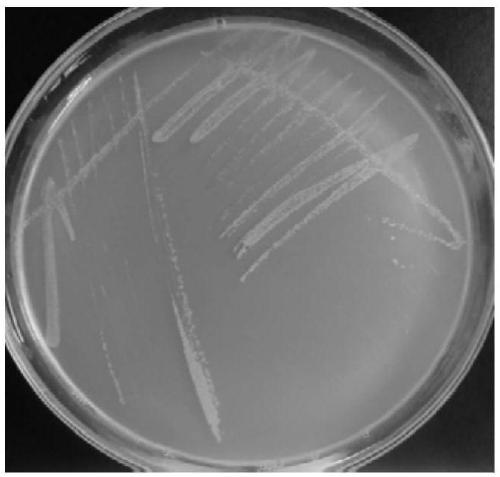

[0029] Isolation and Identification of Example 1 Bacterial Strain HS-K1

[0030] 1. Strain Isolation

[0031] Take 25ml of rice vinegar, white vinegar, fruit vinegar and other fermented liquids from different vinegar factories and different vinegar workshops, add them to 225ml of sterilized physiological saline, shake well, take 1ml of samples and add them to 9ml of sterile physiological saline, and put them on the vortex mixer After mixing evenly, take 1ml of the diluted solution and add it to 9ml of normal saline, and so on. Select 3 suitable concentrations and apply them to the solid medium (glucose 50g, yeast extract 5g, distilled water 1000mL, adjust the pH to 6.5, add agar powder 15g / L.) plate with 20g / L calcium carbonate in turn, 28 Cultivate for 48-72 hours at ℃. Select the bacterial strain that produces a transparent circle on the plate and set aside.

[0032] 2. Strain re-screening

[0033] Inoculate the initially screened strains on a re-screened solid medium (g...

Embodiment 2

[0043] Application of Example 2 bacterial strain HS-K1 in rice vinegar brewing

[0044] 1. Preparation of strain seed solution

[0045] The preparation of first-level seed liquid: according to the inoculum size of 10% (v / v), make the number of viable bacteria about 10 7Inoculate 3L liquid medium (1L liquid medium formula: glucose 5g, peptone 4g, yeast extract 3g, acetic acid 30ml, ethanol 30ml, distilled water 940ml) with cfu / ml European bacillus omae HS-K1 bacterial liquid, 28 ℃, Shake the flask at 150r / min for 20h.

[0046] Preparation of the secondary seed solution: select a 50L liquid fermenter, add 20L rice wine with an alcohol content of 5% vol, and insert the primary seed solution according to the inoculation amount of 15% (v / v). Keep the temperature at 28-30°C, stir at 160r / min, and ventilate at 0.2vvm, and ferment for 14h.

[0047] 2. Fermentation of rice vinegar

[0048] Select a 500L liquid fermenter, add 100L rice wine with an alcohol content of 5% vol, and ins...

Embodiment 3

[0052] Application of Example 3 bacterial strain HS-K1 in white vinegar brewing

[0053] 1. Preparation of strain seed solution

[0054] The preparation of first-level seed liquid: according to the inoculum size of 10% (v / v), make the number of viable bacteria about 10 7 Inoculate 3L liquid medium (1L liquid medium formula: glucose 5g, peptone 4g, yeast extract 3g, acetic acid 30ml, ethanol 30ml, distilled water 940ml) with cfu / ml European bacillus omae HS-K1 bacterial liquid, 28 ℃, Shake the flask at 150r / min for 20h.

[0055] The preparation of secondary seed liquid: select 50L liquid fermenter for use, add 20L alcoholic strength and be the wine liquid (with edible alcohol deployment) of 5%vol, add liquid vinegar fermentation and use nutrient salt 0.9g, glucose 2.5g, according to 15% ( The inoculation amount of v / v) is inserted into the primary seed solution. Keep the temperature at 28-30°C, stir at 160r / min, and ventilate at 0.2vvm, and ferment for 15h.

[0056] 2. Ferm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com