Environment-friendly high-strength and easy-to-cut aluminum alloy and preparation method thereof

A high-strength, easy-cutting technology, applied in the field of high-strength easy-cutting aluminum alloys and its preparation, can solve problems such as poor hardness of materials, easy separation of cutting tools and workpieces, obstacles to the widespread application of lead-containing aluminum alloys, and achieve improved Strength, reduction of adverse effects, enhancement of solid solution strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

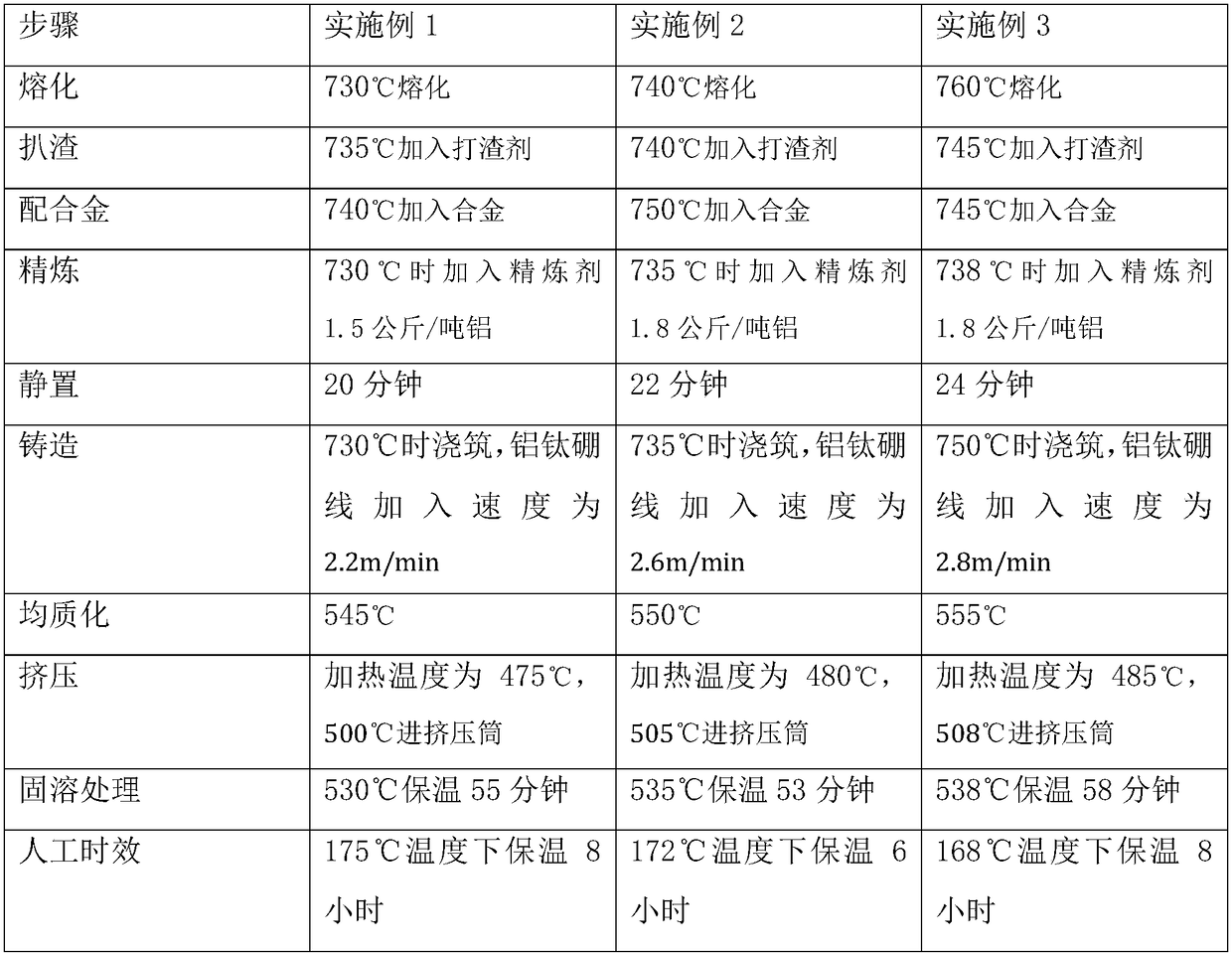

Examples

Embodiment

[0028] An environmentally friendly high-strength free-cutting aluminum alloy, comprising the following components in parts by weight: Si0.6-1.4, Fe≤0.7, Cu 0.2-0.5, Mn 0.2-1.0, Mg 0.6-1.2, Cr≤0.3, Bi0.5~1.5, single content of other impurities≤0.05, total impurities≤0.15, balance is Al.

[0029] A method for preparing an environmentally friendly high-strength free-cutting aluminum alloy, comprising the following steps:

[0030] 1) Melting: Put the aluminum ingot of the AL99.70 grade in the GB / T 1196-2008 standard into the furnace and heat it to 720-760°C for melting;

[0031] 2) Slag removal: Sprinkle the slag removal agent evenly into the furnace at 735±20°C and stir it fully for 10-15 minutes, remove the scum on the surface of the aluminum liquid with a rake, and the amount of the slag removal agent is calculated per ton 0.2~0.4KG;

[0032] 3) Alloy: Si, Fe, Cu, Mn, Mg, Cr, Bi are added when the melt temperature is 730-760°C, among which Si, Cu, Mn, Bi are added in the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com