Aqueous coating for separator of lithium ion battery, preparation method and application thereof

A lithium-ion battery and water-based coating technology, which is applied to secondary batteries, battery pack components, separators/films/diaphragms/spacer components, etc., to improve cycle performance and avoid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

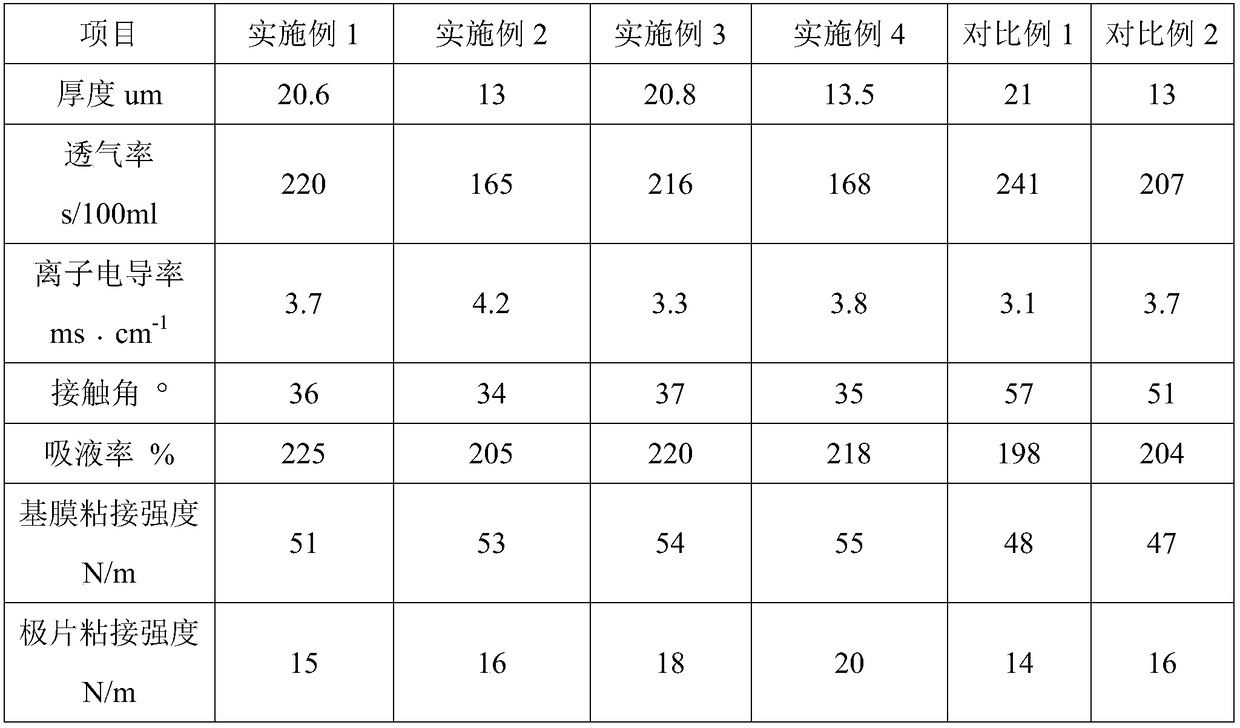

Embodiment 1

[0026] A water-based coating for lithium-ion battery separators, the raw materials of which include the following components in parts by mass: 80 parts of water-based PVDF powder SOLVAY 21216, 3 parts of polymethyl methacrylate binder, surfactant fluoroalkyl 3 parts of methoxy ether alcohol, 6 parts of dispersant carboxymethyl cellulose, 0.3 part of photosensitizer benzophenone, 0.4 part of emulsifier Tween20.

[0027] The above-mentioned lithium-ion battery diaphragm water-based coating and the preparation method of the lithium-ion battery diaphragm comprising the coating, the specific steps are as follows:

[0028] 1) According to the ratio of raw materials described in this example, add fluoroalkyl methoxy ether alcohol and carboxymethyl cellulose into deionized water, and stir rapidly for 20 minutes to obtain a mixed solution;

[0029] 2) Add benzophenone, polymethyl methacrylate adhesive, and water-based PVDF powder SOLVAY21216 to the mixed solution to form a mixed soluti...

Embodiment 2

[0033] A water-based coating for lithium-ion battery separators, the raw materials of which include the following components in parts by mass: 90 parts of water-based PVDF powder ArKema 761A, 5 parts of polyethyl methacrylate binder, surfactant fluoroalkyl 4 parts of ethoxy ether alcohol, 15 parts of dispersant hydroxypropyl methylcellulose, 0.4 part of photosensitizer diphenyl ethyl ketone, 0.3 part of emulsifier Tween80.

[0034] The above-mentioned lithium-ion battery diaphragm water-based coating and the preparation method of the lithium-ion battery diaphragm comprising the coating, the specific steps are as follows:

[0035] 1) According to the ratio of raw materials described in this example, add fluoroalkyl ethoxy ether alcohol and hydroxypropyl methylcellulose into deionized water, and stir rapidly for 25 minutes to obtain a mixed solution;

[0036] 2) Add diphenyl ethyl ketone, polyethyl methacrylate adhesive, and water-based PVDF powder ArKema 761A to the mixed solut...

Embodiment 3

[0039] A water-based coating for lithium-ion battery separators, the raw materials of which include the following components in parts by mass: 85 parts of water-based PVDF powder SOLVAY8808, 7 parts of polymethyl methacrylate binder, surfactant polyoxyethylene alkyl 6 parts of amide, 15 parts of dispersant carboxymethyl cellulose, 0.5 part of photosensitizer benzophenone, 0.3 part of emulsifier sodium polyacrylate.

[0040] The above-mentioned lithium-ion battery diaphragm water-based coating and the preparation method of the lithium-ion battery diaphragm comprising the coating, the specific steps are as follows:

[0041] 1) Add polyoxyethylene alkylamide and carboxymethyl cellulose to deionized water, and stir rapidly for 30 minutes to obtain a mixed solution;

[0042]2) Add benzophenone, polymethyl methacrylate adhesive, and water-based PVDF powder SOLVAY8808 to the mixed solution obtained in step 1) to form a mixed solution with a solid content of 10%, and stir at a speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com