A kind of production process of Longshan jade nano-microcrystalline jade craft board

A technology of nano-crystal and production process, which is applied in manufacturing tools, glass pressing, glass forming, etc., can solve the problem of uniformity and fineness of plate material, insufficient flatness and stability, and is not conducive to improving the related performance of process plate structure. , The control is not meticulous and precise, and the curing control is meticulous and precise, the production cycle is shortened, and the degree of precision is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

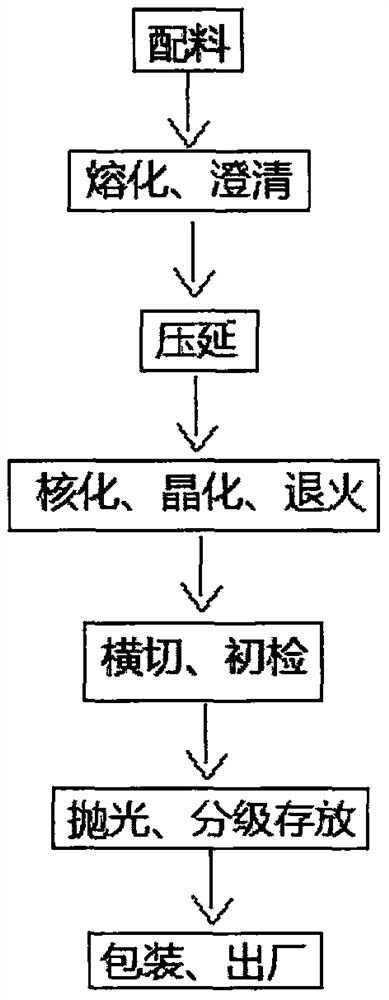

[0030] A kind of production technology of Longshan jade nano microcrystalline jade craft plate, such as figure 1 shown, including the following steps:

[0031] (1) Ingredients: When the production plant feeds the raw materials, inspect each mineral raw material. If the particle size is between 40 and 100 mesh, and the fluctuation of the composition is less than 0.5%, it will be accepted as a qualified raw material and put in the raw material warehouse. In the silo; measure the water content of each mineral raw material before use, and after the computer batching correction, they enter the corresponding silo through the elevator to prepare the batching; the computer batching system is turned on, and after automatic weighing and correction, each raw material is conveyed into the strong machine through the belt. Mixer, at the same time, accurately weigh the auxiliary small material into the powerful mixer, start the mixer, stir for 20 minutes, and mix evenly; the mixture is trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com