Modified epoxy resin, preparation method and application thereof, cathodic electrophoretic coating and preparation method and application thereof

A cathodic electrophoretic coating and epoxy resin technology, which is applied in the coating field, can solve the problem that the stone-strike resistance cannot meet the requirements of automobiles and related parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

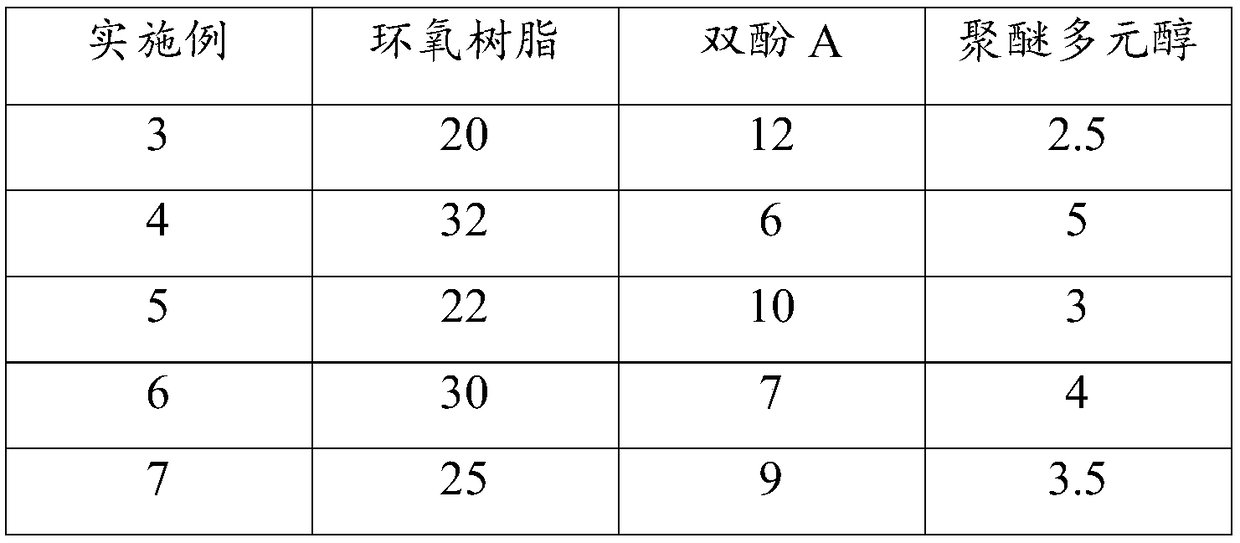

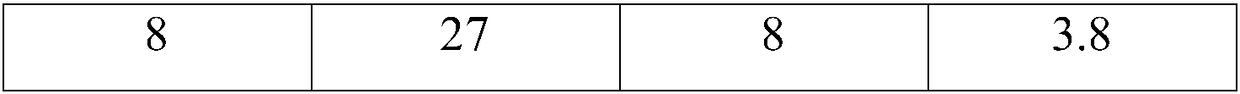

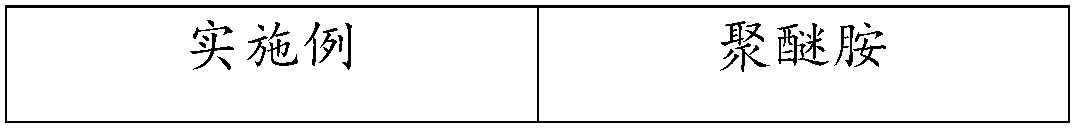

Examples

preparation example Construction

[0134] According to the second aspect of the present invention, the preparation method of modified epoxy resin is provided, and method comprises the following steps:

[0135] (a) bisphenol A and polyether polyol react with epoxy resin under catalyst, make hydroxyl and epoxy group react;

[0136] (b) adding a ketimine-containing alcohol in step (a), so that the hydroxyl group reacts with the epoxy group;

[0137] (c) Add carbamate-containing isocyanate, polyether amine and solvent in step (b), so that the amino group reacts with the epoxy group, and the isocyanate reacts with the hydroxyl group on the epoxy resin to obtain a modified epoxy resin resin.

[0138] Bisphenol A and polyether polyol react with epoxy resin under the catalyst to make the hydroxyl group react with the epoxy group, then add the alcohol containing ketimine to make the hydroxyl group react with the epoxy group, and then add the amino group Formic acid ester isocyanate, polyether amine and solvent make th...

Embodiment 1

[0185] 1. Modified epoxy resin

[0186] A modified epoxy resin is mainly prepared from the following raw materials in parts by weight:

[0187] 26.09 parts of epoxy resin 128E, 8.49 parts of bisphenol A, 3.67 parts of polyether polyol (polyethylene glycol 400), 0.05 parts of triethylamine (TEA), 6.5 parts of alcohol containing ketimine, containing carbamate 13.7 parts of isocyanate, 11.48 parts of polyetheramine D2000, 9.81 parts of MIBK (methyl isobutyl ketone), 15.22 parts of PM (propylene glycol methyl ether), 4.92 parts of PMA (propylene glycol methyl ether acetate).

[0188] 2. Preparation of modified epoxy resin

[0189] (1) Add epoxy resin 128E, bisphenol A, polyether polyol, MIBK, and triethylamine to a four-neck flask equipped with a stirrer, reflux condenser, and thermometer, and keep at 180°C for 4 hours.

[0190] (2) Cool down to 150°C, add alcohol containing ketimine, and keep at 150°C for 4h.

[0191] (3) Cool down to 120°C, add carbamate-containing isocyanate...

Embodiment 2

[0201] 1. Modified epoxy resin

[0202] A modified epoxy resin is mainly prepared from the following raw materials in parts by weight:

[0203] 26.09 parts of epoxy resin 128E, 8.49 parts of bisphenol A, 3.67 parts of polyether polyol (polyethylene glycol 400), 0.05 parts of triethylamine (TEA), 6.5 parts of alcohol containing ketimine, containing carbamate 13.7 parts of isocyanate, 11.48 parts of polyetheramine D2000, 9.81 parts of MIBK (methyl isobutyl ketone), 15.22 parts of PM (propylene glycol methyl ether), 4.92 parts of PMA (propylene glycol methyl ether acetate).

[0204] 2. Preparation of modified epoxy resin

[0205] (1) Add 30 parts by weight of monoethanolamine and 70 parts by weight of MIBK into a four-necked flask equipped with a stirrer, reflux condenser, and thermometer, and react at 170°C for reflux for 12 hours, and keep 170°C under negative pressure of -80kPa Reflux dehydration for 24h, that is, the alcohol containing ketimine is obtained.

[0206] (2) In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com