Preparation method and applications of aqueous reflective radiation type composite heat insulation paint

A technology of reflective heat-insulating coatings and heat-insulating coatings, which is applied in the field of coatings and can solve problems such as cumbersome processes and numerous raw materials for preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

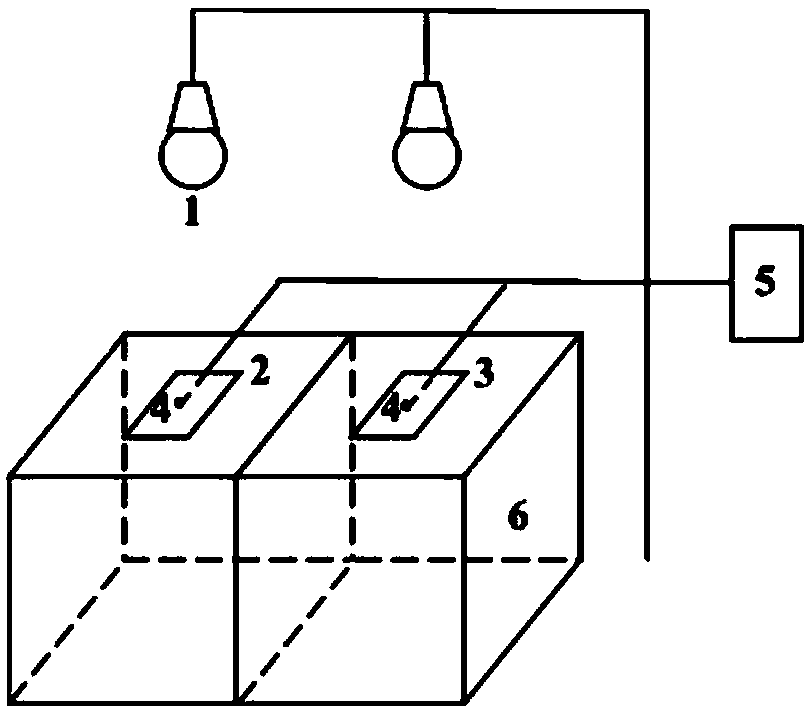

Image

Examples

Embodiment 1

[0028] The reflective coating is made of the following raw materials in parts by weight: rutile titanium dioxide 21, acrylic emulsion 30, deionized water 9, alcohol ester twelve 1.2, polyacrylic defoamer containing hydrophobic particles 0.15, polyacrylic dispersant 1.05. Polyurethane associative thickener 0.1.

[0029] The radiation coating is made of the following raw materials in parts by weight: carbon nanotube 0.075, acrylic acid emulsion 30, deionized water 15, alcohol ester twelve 1.8, polyacrylic acid defoamer containing hydrophobic particles 0.18, sodium lauryl sulfate 0.8. Polyurethane associative thickener 0.3.

[0030] The radiation-reflecting composite heat-insulating coating of the present invention is made by the following specific steps:

[0031] (1) After dispersing 9 parts of deionized water, 0.075 parts of defoamer, and 1.05 parts of polyacrylic acid dispersant evenly, add 21 parts of rutile titanium dioxide, disperse at high speed for 30 minutes, add it to ...

Embodiment 2

[0037]The reflective coating is made of the following raw materials in parts by weight: rutile titanium dioxide 30, acrylic emulsion 35, deionized water 10, alcohol ester twelve 1.5, polyacrylic defoamer containing hydrophobic particles 0.2, polyacrylic dispersant 1.5. Polyurethane associative thickener 0.1.

[0038] The radiation coating is made of the following raw materials in parts by weight: carbon nanotube 0.03, acrylic acid emulsion 35, deionized water 15, alcohol ester twelve 2.0, polyacrylic defoamer containing hydrophobic particles 0.18, sodium lauryl sulfate 1.2. Polyurethane associative thickener 0.3.

[0039] (1) After uniformly dispersing 10 parts of deionized water, 0.1 part of polyacrylic acid defoamer containing hydrophobic particles, and 1.5 parts of polyacrylic dispersant, add 30 parts of rutile titanium dioxide, disperse at high speed for 30 minutes, and add to Finely grind and disperse in a sander, and control the fineness below 30 μm to obtain a titanium...

Embodiment 3

[0045] The reflective coating is made of the following raw materials in parts by weight: rutile titanium dioxide 21, two-component water-based FEVE fluorocarbon resin 30, deionized water 9, alcohol ester twelve 1.2, polyacrylic defoamer containing hydrophobic particles 0.15 , Polyacrylic dispersant 1.05, polyurethane associative thickener 0.1.

[0046] The radiation coating is made of the following raw materials in parts by weight: carbon nanotube 0.075, two-component water-based FEVE fluorocarbon resin 30, deionized water 15, alcohol ester twelve 1.8, polyacrylic defoamer containing hydrophobic particles 0.18, Sodium lauryl sulfate 0.8, polyurethane associative thickener 0.3.

[0047] The radiation-reflecting composite heat-insulating coating of the present invention is made by the following specific steps:

[0048] (1) After dispersing 9 parts of deionized water, 0.075 parts of defoamer, and 1.05 parts of polyacrylic acid dispersant evenly, add 21 parts of rutile titanium d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com