Lead-free all-inorganic perovskite cesium bismuth iodide thin film/n-type silicon heterojunction photodetector and preparation method thereof

A technology of photodetectors and silicon heterojunctions, applied in the field of photodetectors, can solve problems such as poor stability, toxicity, and hindering the application of materials, and achieve the effects of good stability, fast response speed, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

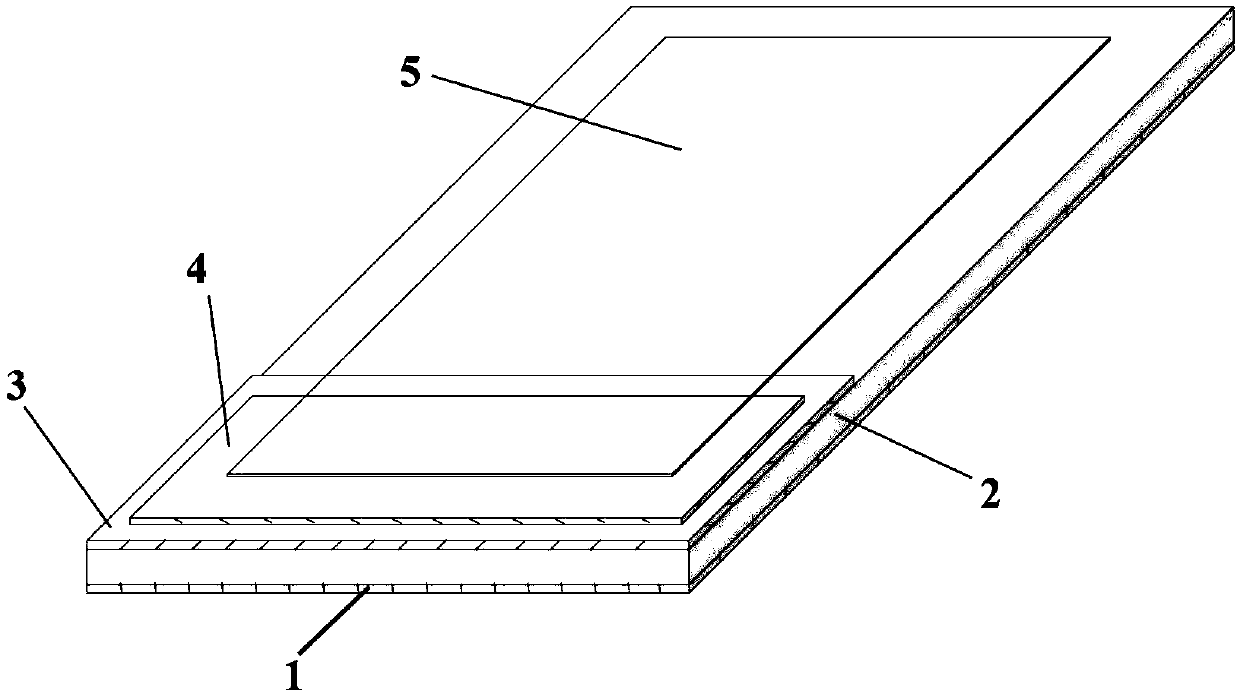

[0032] Such as figure 1 Shown, in this embodiment perovskite CsBi 3 I 10 The structure of the thin film / n-type silicon heterojunction photodetector is as follows: the n-type silicon substrate 2 is used as the base region of the photodetector, and the n-type silicon substrate electrode 1 is arranged on the lower surface of the n-type silicon substrate 2; Cover the upper surface of the n-type silicon substrate 2 with an insulating layer 3, the area of the insulating layer 3 is 1 / 5 to 2 / 3 of the area of the n-type silicon substrate 2, and the boundary of the insulating layer 3 does not exceed the n-type silicon substrate 2 The boundary; on the insulating layer 3 covered perovskite CsBi 3 I 10 Thin film contact electrode 4, perovskite CsBi 3 I 10 The boundary of the film contact electrode 4 does not exceed the boundary of the insulating layer 3; in the perovskite CsBi 3 I 10 Perovskite CsBi is laid on the film contact electrode 4 3 I 10 Thin film 5, perovskite CsBi 3...

Embodiment 2

[0044] Such as figure 1 Shown, in this embodiment perovskite CsBi 3 I 10 The structure of the thin film / n-type silicon heterojunction photodetector is as follows: the n-type silicon substrate 2 is used as the base region of the photodetector, and the n-type silicon substrate electrode 1 is arranged on the lower surface of the n-type silicon substrate 2; Cover the upper surface of the n-type silicon substrate 2 with an insulating layer 3, the area of the insulating layer 3 is 1 / 5 to 2 / 3 of the area of the n-type silicon substrate 2, and the boundary of the insulating layer 3 does not exceed the n-type silicon substrate 2 The boundary; on the insulating layer 3 covered perovskite CsBi 3 I 10 Thin film contact electrode 4, perovskite CsBi 3 I 10 The boundary of the film contact electrode 4 does not exceed the boundary of the insulating layer 3; in the perovskite CsBi 3 I 10 Perovskite CsBi is laid on the film contact electrode 4 3 I 10 Thin film 5, perovskite CsBi 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com