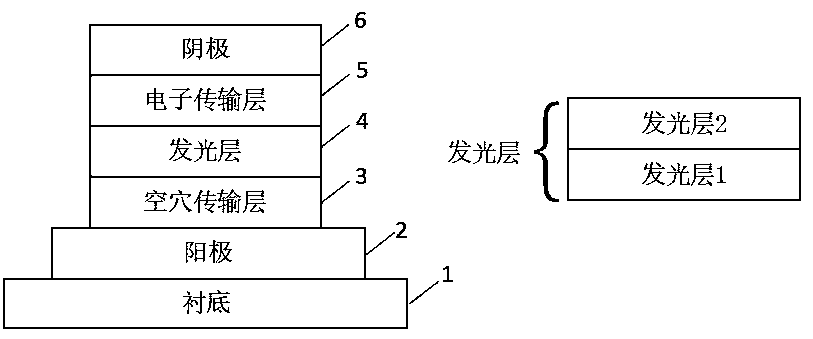

A white light organic electroluminescent device with two layers and two precursors without spacers

An electroluminescent device and parent technology, which is used in the manufacture of electric solid devices, semiconductor devices, semiconductor/solid-state devices, etc. problem, to reduce the interface barrier, stabilize the luminescence spectrum, and achieve the effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of organic light-emitting devices can be carried out in a multi-source organic molecular vapor deposition system. The detailed process is as follows:

[0034] [1] The substrate used in the experiment is ITO conductive glass. First, use acetone, absolute ethanol, and deionized water to repeatedly scrub the front and back sides of the ITO glass to remove surface impurities and metal ions.

[0035] [2] Sonicate the wiped ITO substrate with acetone, ethanol, and deionized water for 10 minutes in sequence, and then perform ultraviolet treatment for 10 minutes after drying.

[0036] [3] The treated ITO glass was placed in a multi-source organometallic molecular vapor deposition system in a face-down manner through a glove box. (See Chinese patent: ZL03110977.2, "Pot-increasing evaporation source for organic electroluminescent coating machine"). There are 10 organic evaporation sources and 3 metal electrode evaporation sources in the evaporation table, which c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com