A method for synthesize mother liquor of ternary cathode material precursor of lithium ion battery

A technology for lithium ion batteries and positive electrode materials is applied in the field of comprehensive utilization of mother liquor in the synthesis process of precursors of ternary positive electrode materials of lithium batteries, so as to achieve the effects of being easy to return to use and reducing production time cost and raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

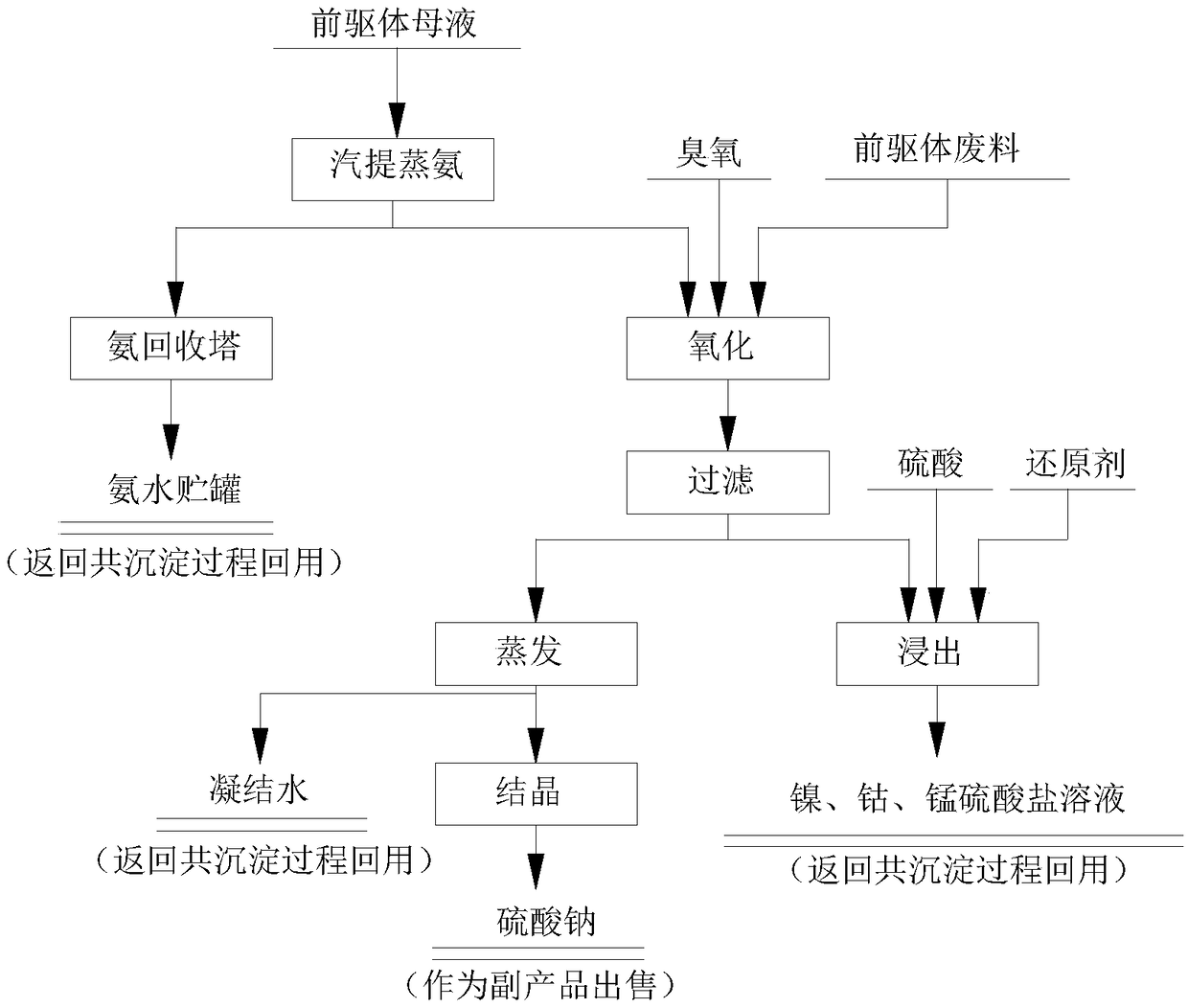

[0019] see figure 1 A method for comprehensive utilization of mother liquor in the synthesis process of a lithium battery ternary cathode material precursor, comprising the following steps:

[0020] The first step: the ternary precursor mother liquor is passed from top to bottom into the stripping tower deamination system and the rectification tower for deamination. The deamination residence time of the mother liquor per unit volume is controlled to 1.0h, and the ammonia gas obtained by distilling ammonia from the mother liquor is recovered. After the tower absorbs, it is passed into the ammonia water storage tank and can be returned to the co-precipitation process for use;

[0021] Step 2: Add the ternary precursor mother liquor after deamination in step 1 to the reaction tank. The ternary precursor waste is nickel-cobalt-manganese hydroxide with unqualified main element ratio or physical properties in the production process, ternary precursor The amount of waste added is 0....

Embodiment 2

[0025] see figure 1 A method for comprehensive utilization of mother liquor in the synthesis process of a lithium battery ternary cathode material precursor, comprising the following steps:

[0026] The first step: the ternary precursor mother liquor is passed from top to bottom into the stripping tower deamination system and the rectification tower for deamination. The deamination residence time of the mother liquor per unit volume is controlled to 1.0h, and the ammonia gas obtained by distilling ammonia from the mother liquor is recovered. After the tower absorbs, it is passed into the ammonia water storage tank and can be returned to the co-precipitation process for use;

[0027] Step 2: Add the ternary precursor mother liquor after deamination in step 1 to the reaction tank. The ternary precursor waste is nickel-cobalt-manganese hydroxide with unqualified main element ratio or physical properties in the production process, ternary precursor The amount of waste added is 1....

Embodiment 3

[0031] see figure 1 A method for comprehensive utilization of mother liquor in the synthesis process of a lithium battery ternary cathode material precursor, comprising the following steps:

[0032] The first step: the ternary precursor mother liquor is passed from top to bottom into the stripping tower deamination system and the rectification tower for deamination. The deamination residence time of the mother liquor per unit volume is controlled to 0.5h, and the ammonia gas obtained by distilling ammonia from the mother liquor is recovered. After the tower absorbs, it is passed into the ammonia water storage tank and can be returned to the co-precipitation process for use;

[0033] Step 2: Add the ternary precursor mother liquor after deamination in step 1 to the reaction tank. The ternary precursor waste is nickel-cobalt-manganese hydroxide with unqualified main element ratio or physical properties in the production process, ternary precursor The amount of waste added is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com