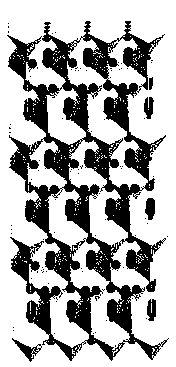

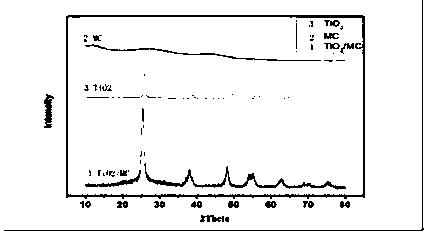

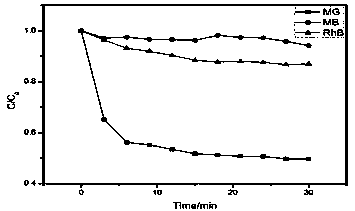

Organic dye adsorbent double mesoporous TiO2/carbon and preparation method thereof

An organic dye and double mesoporous technology, applied in the field of water pollution treatment, can solve the problems of ecological environment and drinking water hazards, heavy metals and biological toxicity, high content of organic pollutants, etc., and achieve good thermal stability and high recycling rate , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. (1) Synthesis of template silica microspheres: Add 500ml of absolute ethanol, 40ml of deionized water, and 20ml of ammonia water into a 1000ml beaker in turn, stir for 30min to obtain a uniform transparent solution ①, quickly add 30ml to the solution ① Ethyl orthosilicate, stirred at room temperature for 4 hours, the obtained milky white suspension ②, the solution ② was centrifuged at 13000rpm for five minutes to obtain a solid, washed 3 times with water and then 3 times with ethanol, and the washed The solid was vacuum-dried at 70°C for 12 hours, and finally calcined in air at 500°C for 3 hours to obtain silica microspheres;

[0020] (2) Synthesis of mesoporous carbon: 1.0g of silica microspheres and 1.2g of 1-allyl-2-thiourea were sequentially added to a crucible filled with 10-20ml of deionized water, heated in a water bath to 80°C, Stir for 1 hour to completely dissolve 1-allyl-2-thiourea, then put the crucible in an oven and dry it for 24 hours until it becomes ...

Embodiment 2

[0025] 1. (1) Synthesis of silica microspheres as template agent: add 500ml of absolute ethanol, 50ml of deionized water, and 30ml of ammonia water into a 1000ml beaker in turn, stir for 50min to obtain a uniform transparent solution ①, quickly add 50ml into the solution ① Ethyl orthosilicate, stirred at room temperature for 6 hours, the obtained milky white suspension ② was placed in 15000rpm centrifugation for 5 minutes to obtain a solid, washed 5 times with water and then 5 times with ethanol. The solid was vacuum-dried at 90°C for 24 hours, and finally calcined in air at 600°C for 5 hours to obtain silica microspheres;

[0026] (2) Synthesis of mesoporous carbon: 2.0g of silica microspheres and 2.4g of 1-allyl-2-thiourea were sequentially added to a crucible containing 20ml of deionized water, heated to 90°C in a water bath, and stirred for 3 Dissolve the 1-allyl-2-thiourea completely within 1 hour, then put the crucible in an oven and dry it for 30 hours until it becomes ...

Embodiment 3

[0031]1. (1) Synthesis of silica microspheres as template agent: add 500ml of absolute ethanol, 45ml of deionized water, and 25ml of ammonia water into a 1000ml beaker in turn, stir for 30min to obtain a uniform transparent solution ①, quickly add 40ml into the solution ① Ethyl orthosilicate, stirred at room temperature for 5 hours, the obtained milky white suspension ②, put the solution ② at 13000-15000rpm and centrifuge for 5 minutes to obtain a solid, wash 4 times with water and 4 times with ethanol, wash The final solid was vacuum-dried at 80°C for 18 hours, and finally calcined in air at 550°C for 4 hours to obtain silica microspheres;

[0032] (2) Synthesis of mesoporous carbon: 1.5g of silica microspheres and 1.8g of 1-allyl-2-thiourea were sequentially added to a crucible containing 15ml of deionized water, heated in a water bath to 85°C, and stirred for 2 Dissolve the 1-allyl-2-thiourea completely within 1 hour, then put the crucible in an oven and dry it for 27 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com