A method for the controllable preparation of three-dimensional nanoporous graphene powder by chemical vapor deposition

A technology of chemical vapor deposition and porous graphene, which is applied in the direction of chemical instruments and methods, graphene, nano-carbon, etc., to achieve the effect of lowering higher requirements, controlling the size, and eliminating soft and hard agglomerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

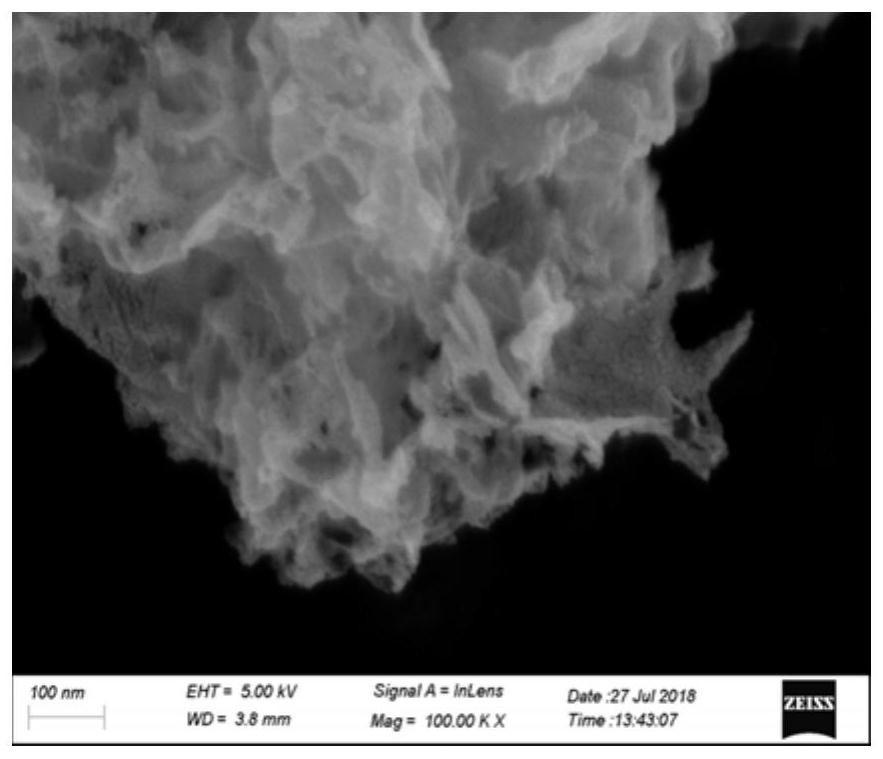

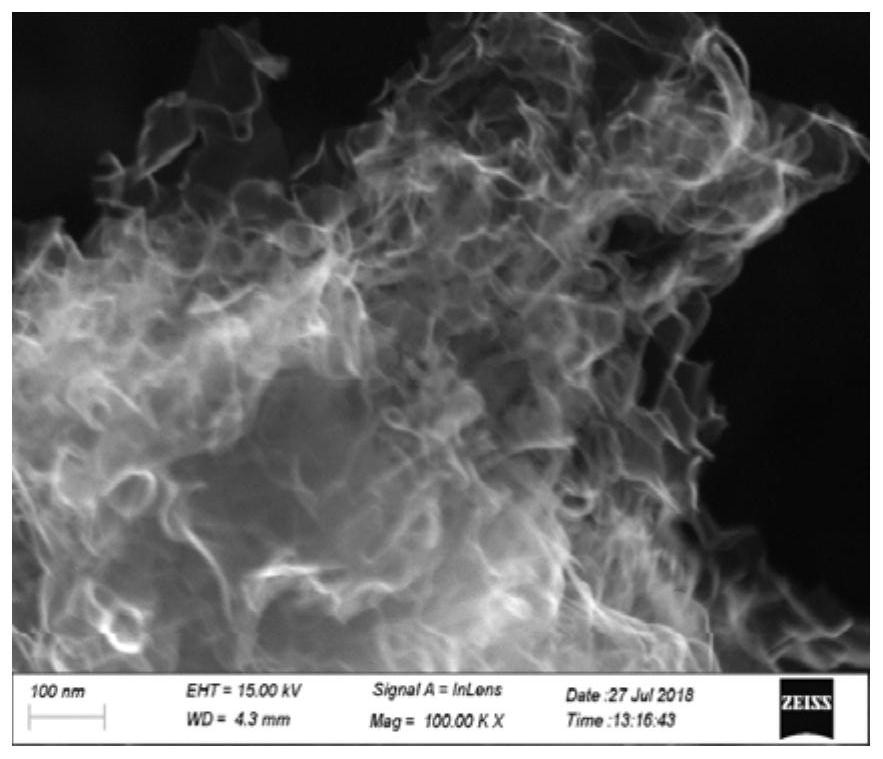

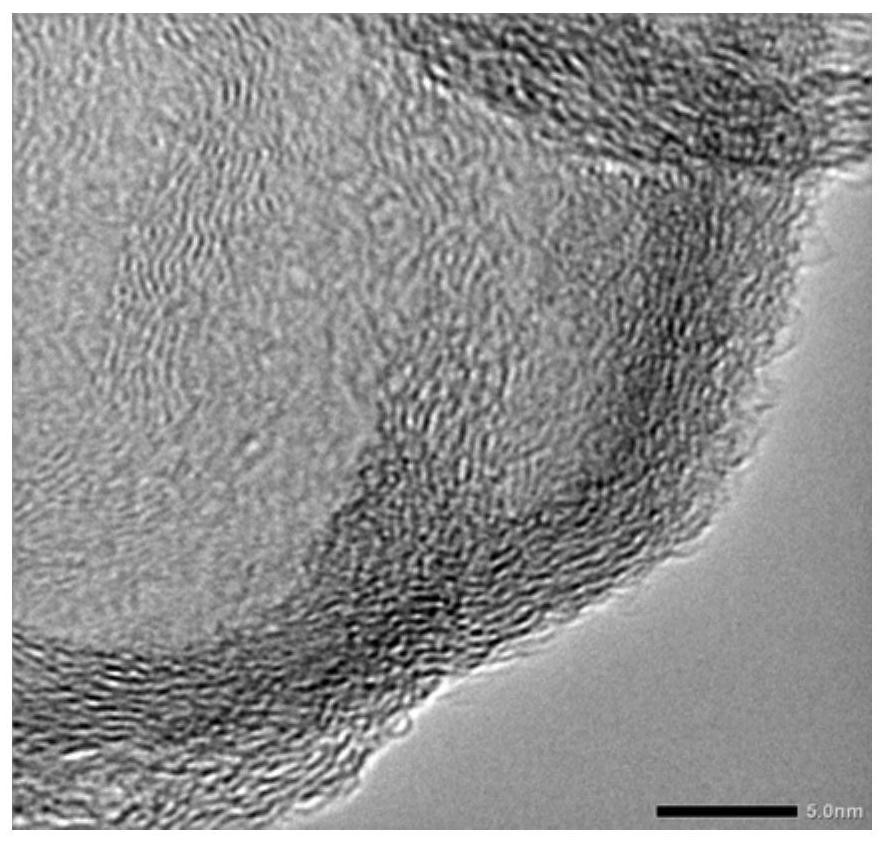

Image

Examples

Embodiment 1

[0032] 1. Dissolve 11g of sodium formate in 50mL of deionized water, then add it to 100g of magnesium oxide powder (500 mesh), stir and mix evenly, dry the resulting mixture at 100°C until the moisture content is less than 1%, and grind it to make Powder, so that the particle size of the powder is ≥500 mesh.

[0033] 2. Put the solid powder obtained in step 1 into a tube furnace, and pass it into the dried air at 850°C for high-temperature activation treatment. The activation time is 20 minutes. After the high-temperature activation treatment, grind it Milling.

[0034] 3. Place the solid powder activated at high temperature in step 2 in a tube furnace, heat it to 300°C under air-isolated conditions, and feed 10 mL of acrylic acid into the tube furnace at a rate of 1 mL / min to make the acrylic acid in the solid A polymerization reaction is carried out on the surface of the powder to obtain a solid powder coated with polyacrylic acid.

[0035] 4. Place the solid powder coated...

Embodiment 2

[0045] 1. Dissolve 9g of sodium acetate in 50mL of deionized water, then add 100g of magnesium hydroxide (400 mesh), stir and mix evenly, dry the resulting mixture at 100°C until the moisture content is less than 1%, and grind it to make powder , so that the powder particle size ≥ 400 mesh.

[0046] 2. Put the solid powder obtained in step 1 into a tube furnace, and pass it into the dried air at 850°C for high-temperature activation treatment. The activation time is 25 minutes. After the high-temperature activation treatment, grind it Milling.

[0047] 3. Place the solid powder activated at high temperature in step 2 in a tube furnace, heat it to 400°C under air-isolated conditions, and feed 10 mL of methyl acrylate into the tube furnace at a rate of 1 mL / min to make acrylic acid The methyl ester is polymerized on the surface of the solid powder to obtain a solid powder coated with polymethyl acrylate.

[0048] 4. Place the solid powder coated with polymethyl acrylate on the...

Embodiment 3

[0051] 1. Dissolve 7g of sodium oxalate in 50mL of deionized water, then add 100g of magnesium carbonate (300 mesh), stir and mix evenly, dry the resulting mixture at 100°C until the moisture content is less than 1%, and grind it to make powder. Make the powder particle size ≥ 300 mesh.

[0052] 2. Put the solid powder obtained in step 1 into a tube furnace, and pass it into the dried air at 900°C for high-temperature activation treatment. The activation time is 35 minutes. After the high-temperature activation treatment, grind it Milling.

[0053] 3. Place the solid powder activated at high temperature in step 2 in a tube furnace, heat it to 450°C under air-isolated conditions, and feed 10 mL of ethyl acrylate into the tube furnace at a rate of 1 mL / min to make acrylic acid Ethyl is polymerized on the surface of the solid powder to obtain a solid powder coated with polyethyl acrylate.

[0054] 4. Place the solid powder coated with polyethyl acrylate on the surface in step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com