Solidified cement sandwich plate and preparation method thereof

A sandwich panel and cement technology, which is applied in the field of construction and decoration materials, can solve the problems of easy aging, swelling, deformation, and separation of the bonding layer, and achieve the effects of avoiding glue aging, improving stability, and uniform bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 A solidified cement sandwich panel

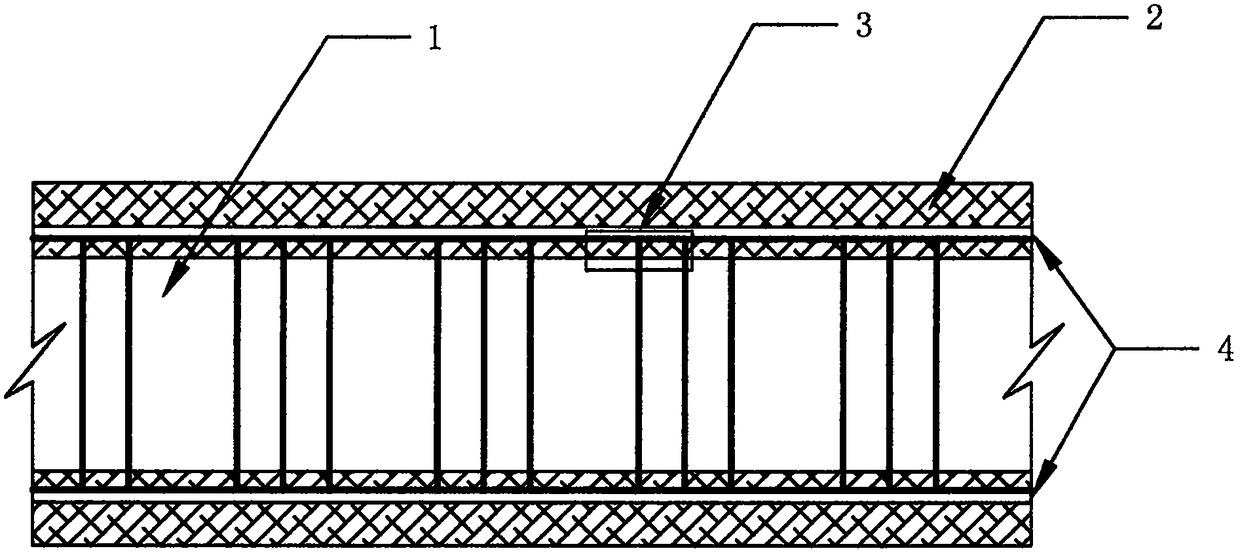

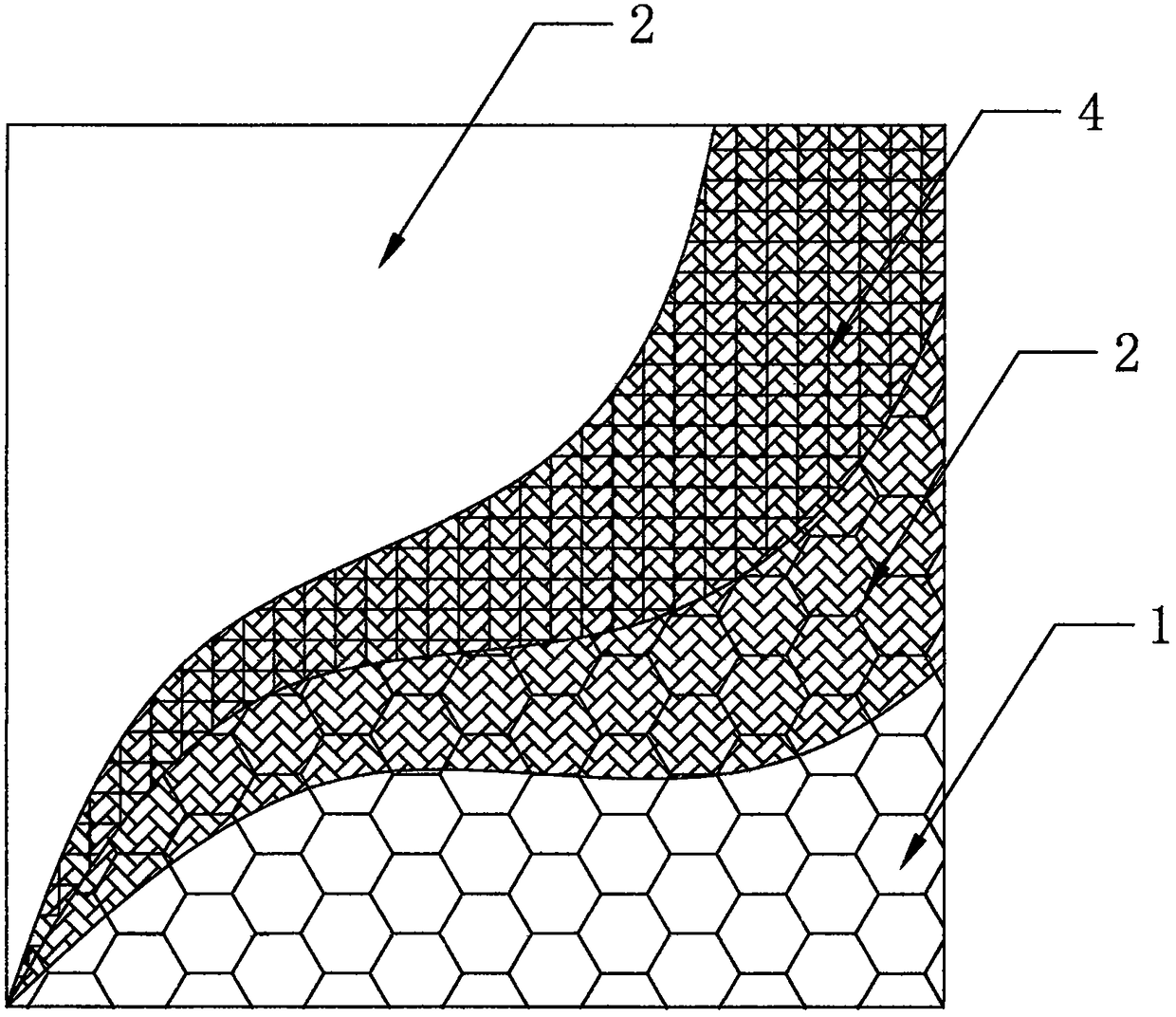

[0023] The solidified cement sandwich panel, such as figure 1 As shown, it includes cement mortar layer 2, honeycomb aluminum layer 1 and fiber mesh cloth 4. The cement mortar layer 2 is divided into an upper mortar layer and a lower mortar layer. The upper and lower sides of the honeycomb aluminum layer 1 are respectively solidified with an upper mortar layer and a lower mortar layer. The two cement mortar layers are filled with low-alkali glass fiber mesh cloth 4, and a layer of intersecting solidification layer 3 is formed between the cement mortar layer 2 and the honeycomb aluminum layer 1.

[0024] As an embodiment, the thickness of the upper mortar layer and the lower mortar layer is 8mm; the thickness of the honeycomb aluminum layer is 20mm.

Embodiment 2

[0025] Embodiment 2 A kind of preparation method of setting type cement sandwich panel

[0026] The preparation method is realized through the following steps:

[0027] First lay a layer of cement mortar a (laying thickness 8mm) in the prepared mold (size 1220×1220×25mm), and then lay a layer of fiber mesh cloth 1 (size 1200mm) on the laid cement mortar a ×1200mm), lay the first layer of honeycomb aluminum on the laid layer of fiber mesh cloth 1 (the laying thickness is 20mm), then put the mold and materials into the hydraulic press and pressurize until the honeycomb aluminum sinks into the mortar for 3mm and then stops , take off the mold after the cement mortar solidifies in the natural environment for 4 hours;

[0028] Lay a layer of cement mortar b (laying thickness is 8mm) in another forming mold (size is 1220×1220×33mm), and then lay a layer of fiber mesh cloth 2 (size is 1200× 1200mm), and then cover the above-mentioned completed cement board with honeycomb aluminum o...

Embodiment 3

[0034] Example 3 A preparation method of solidified cement sandwich panel

[0035] This preparation method, except following feature, other features are identical with embodiment 2:

[0036] The components of the cement mortar a and b are: 33.2% of cement, 39% of 40-70 mesh river sand, 25% of water, 0.5% of concrete water reducing agent, 0.30% of reinforcing fiber and 2% of thickener. Wherein, the cement is 52.5R ordinary cement.

[0037] The thickener adopts cellulose ether organic thickener.

[0038] The pressure of the hydraulic treatment is 28MPa.

[0039] The thickness of the cement mortar a and b is 5mm, and the thickness of the honeycomb aluminum can be 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com