Hole transport material with phenoxazine as core structure, and synthetic method and application thereof

A technology of hole transport material and core structure, which is applied in the direction of luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve the problems that the photoelectric performance and stability of perovskite solar cells need to be improved, and achieve the promotion of large-scale commercialization The effect of production, good stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

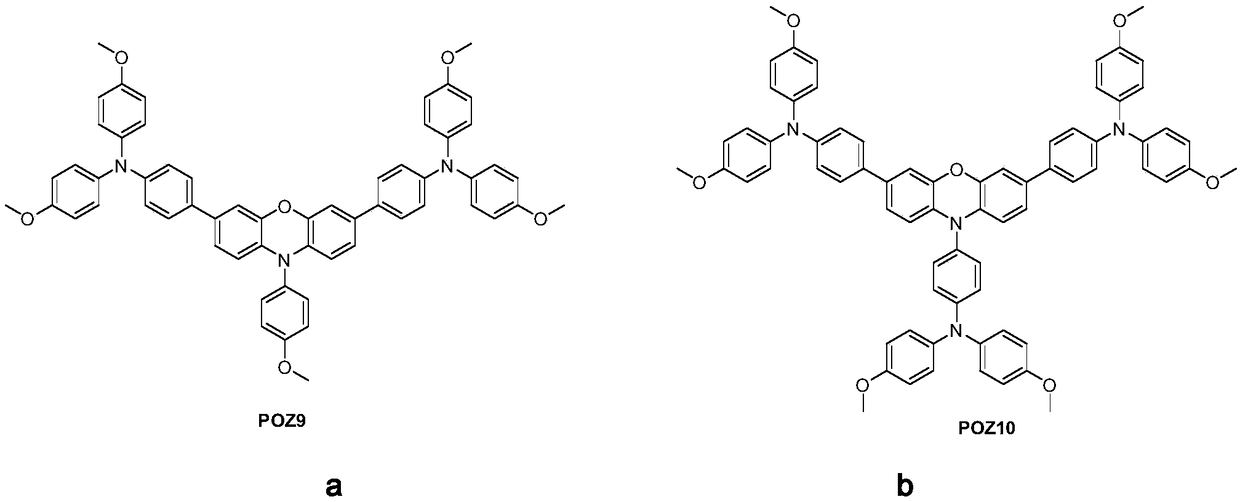

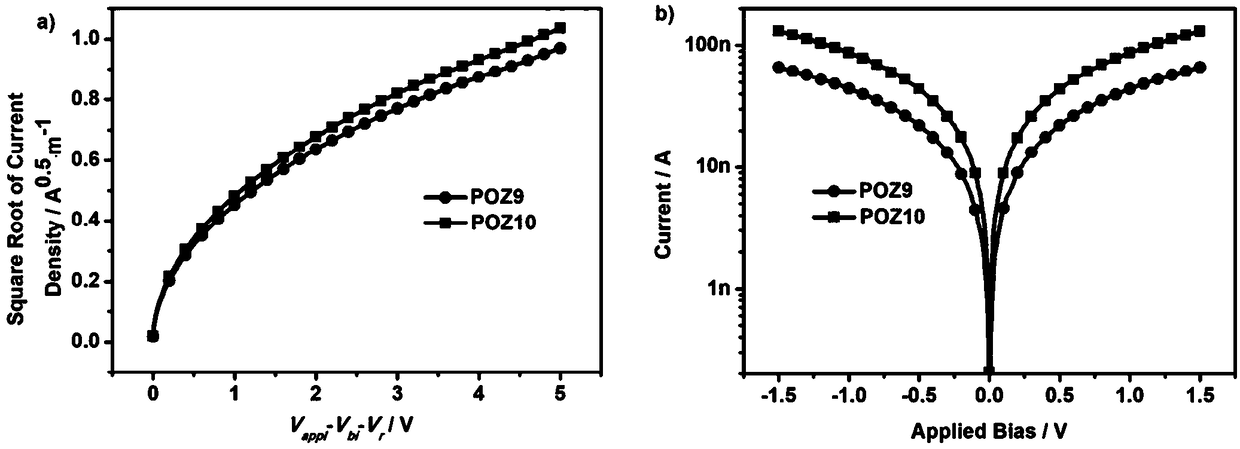

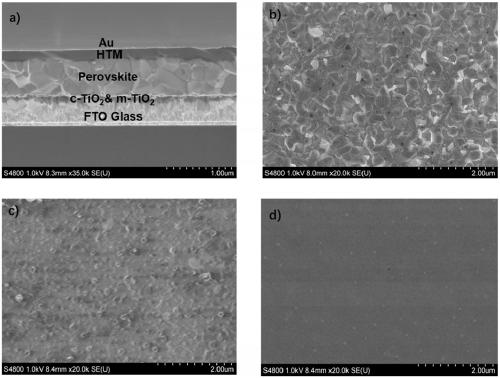

[0044] Synthesis of hole transport material POZ9 and its application in perovskite solar cells:

[0045]

[0046] (i) Add p-methoxybromobenzene (0.823g, 4.40mmol), phenothiazine (0.732g, 4.00mmol), catalyst palladium acetate (0.018g, 0.08mmol), tri-tert-butyl Phosphorus (5% mmol), sodium tert-butoxide (0.577g, 6.00mmol) and solvent toluene (50mL) were stirred uniformly under nitrogen protection at room temperature, and then heated to 110°C for 24h. After the reaction is finished, cool to room temperature, add 50 mL of dichloromethane to the reaction solution, wash with 150 mL of water three times, collect the organic layer, remove the solvent under reduced pressure, and separate and purify the residue with silica gel chromatography, petroleum ether / dichloro Methane (4:1 vol / vol) was used as the eluent and dried in vacuo to obtain compound 1 (0.991 g, yield: 85.7%) as a white solid. 1 H-NMR (CDCl 3 ): δ7.34(d, J=8.7Hz, 2H); 7.14(d, J=8.7Hz, 2H); 7.02(dd, J=7.5, 1.6Hz, 2H);...

Embodiment 2

[0052] Synthesis of hole transport material POZ10 and its application in perovskite solar cells:

[0053]

[0054] (i) Add compound 4 (1.69g, 4.40mmol), phenothiazine (0.732g, 4.00mmol), catalyst palladium acetate (0.018g, 0.08mmol), tri-tert-butylphosphine (5% mmol), sodium tert-butoxide (0.577g, 6.00mmol) and solvent toluene (50mL), stirred evenly under nitrogen protection at room temperature, then heated to 110°C for 24h. After the reaction is finished, cool to room temperature, add 50 mL of dichloromethane to the reaction solution, wash with 150 mL of water three times, collect the organic layer, remove the solvent under reduced pressure, and separate and purify the residue with silica gel chromatography, petroleum ether / dichloro Methane (4:1 vol / vol) was used as the eluent and dried in vacuo to obtain compound 1 (1.618 g, yield: 93.2%) as a white solid. 1 H-NMR (CDCl 3 ): δ7.36(d, J=8.7Hz, 2H); 7.15(d, J=8.7Hz, 2H); 7.04(dd, J=7.5, 1.6Hz, 2H); 6.98-6.90(m, 6H) ;6.86...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com