A kind of anticorrosion coating based on graphene modification and its preparation process

A graphene-modified and anti-corrosion coating technology, applied in the field of coatings, can solve problems such as corrosion spots on the coating and the inability of graphene to fully distribute on the surface of the special layer, so as to prevent the steel from contacting with the air and improve the anti-corrosion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

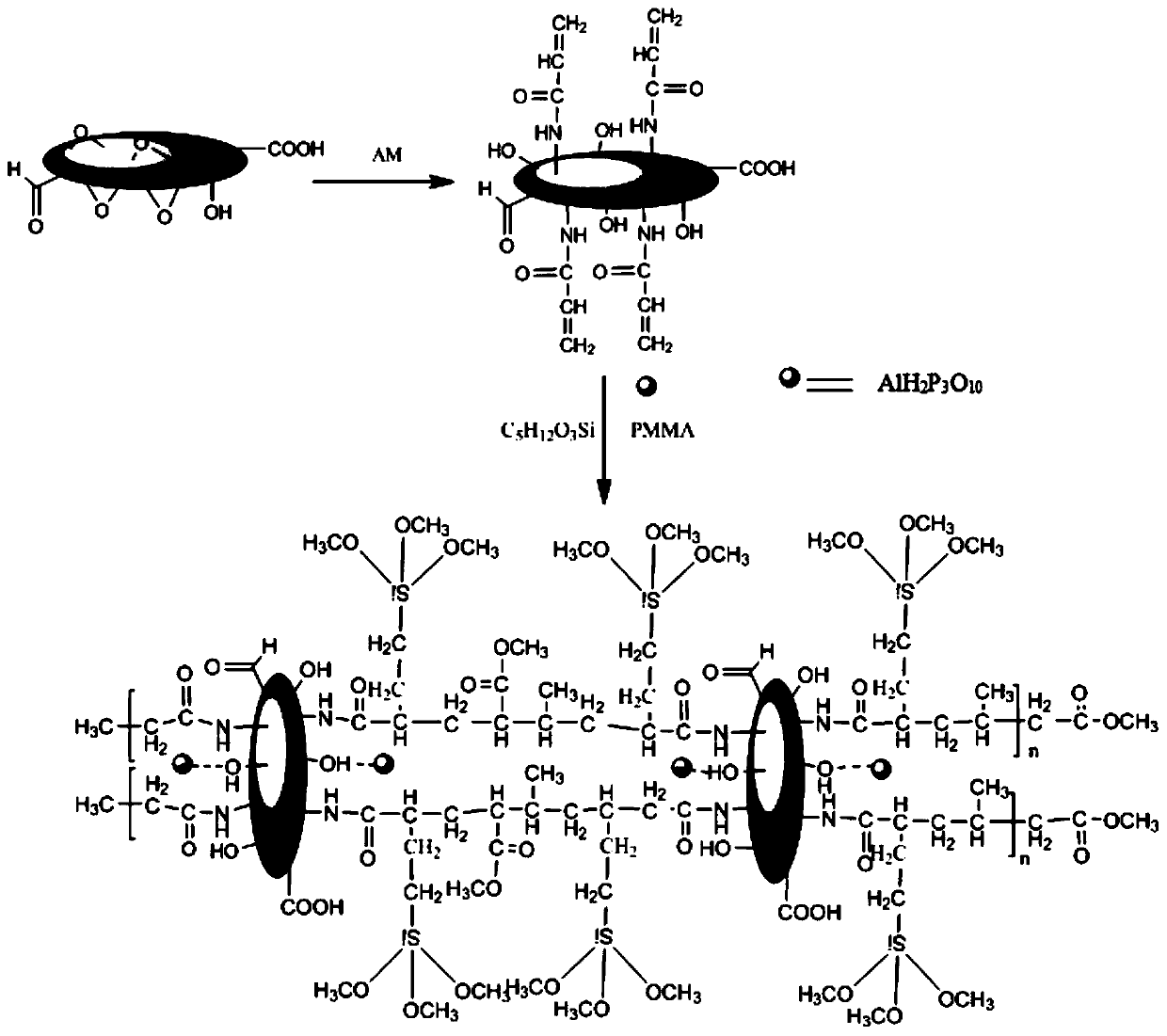

[0029] The preparation process of graphene-based acrylic resin is as follows:

[0030] ① Add 100g graphite powder to 2.3L concentrated sulfuric acid solution, add 50g sodium nitrate to it at the same time, then react in ice water bath for 10-15min, then add 300g potassium permanganate to it, stir for 5-10min and then heat up to 50 React at ℃ for 5-6h, cool to room temperature, then slowly add hydrogen peroxide dropwise until the color of the solution turns dark yellow, then centrifuge and dry to obtain graphene oxide;

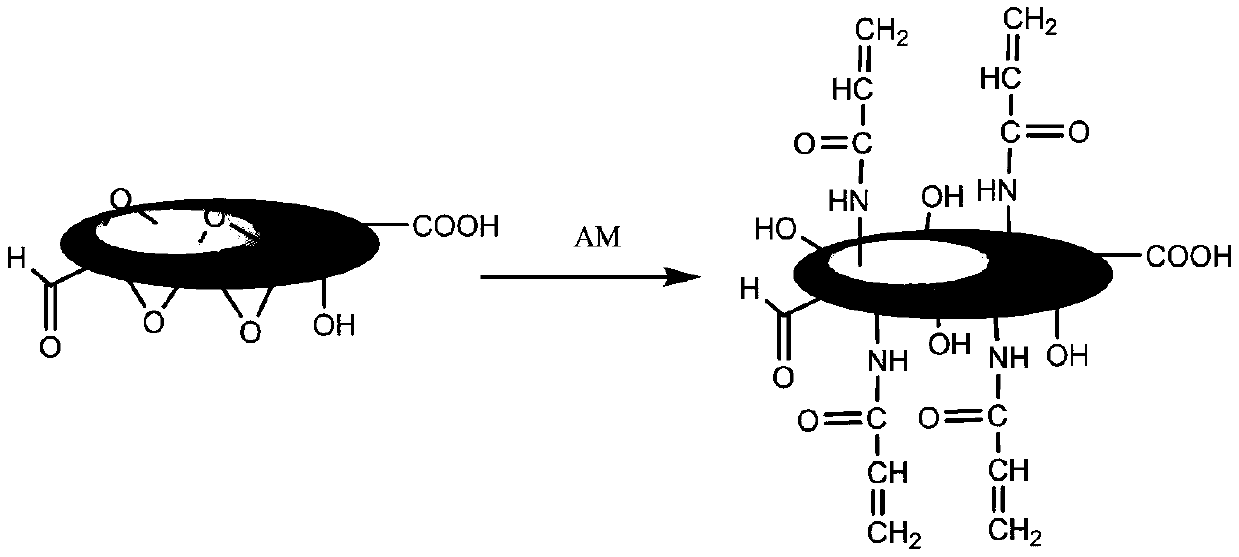

[0031] ② Add 100g of graphene oxide into ethanol, ultrasonically disperse for 5-8min, then add 1.2kg of acrylamide, stir and react at 30-40°C for 10-12h, then filter and wash to obtain modified graphene;

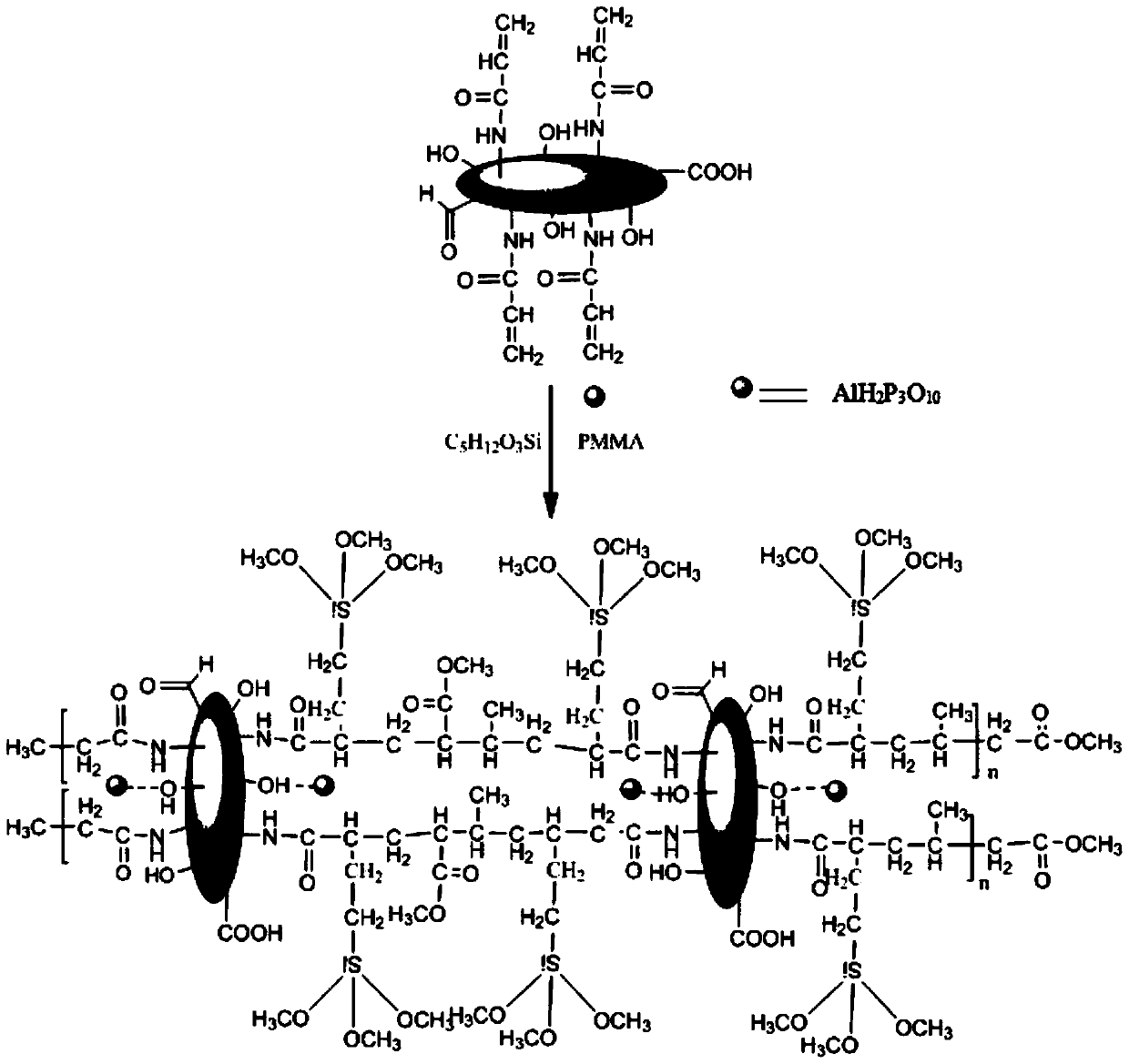

[0032] ③Dissolve 80g of modified graphene in 400mL ethanol solution, and add 40g of aluminum tripolyphosphate to it, disperse evenly by ultrasonic waves, then pour it into a reaction vessel, and add 97g of azobisisobutyronitrile to it, and Nitrogen was passe...

Embodiment 2

[0034] The preparation process of graphene-based acrylic resin is as follows:

[0035] ① Add 100g graphite powder to 2.5L concentrated sulfuric acid solution, add 50g sodium nitrate to it at the same time, then react in ice water bath for 10-15min, then add 300g potassium permanganate to it, stir for 5-10min and then heat up to 50 React at ℃ for 5-6h, cool to room temperature, then slowly add hydrogen peroxide dropwise until the color of the solution turns dark yellow, then centrifuge and dry to obtain graphene oxide;

[0036] ②Add 100g of graphene oxide into ethanol, ultrasonically disperse for 5-8min, then add 1.3kg of acrylamide, stir and react at 30-40°C for 10-12h, then filter and wash to obtain modified graphene;

[0037] ③Dissolve 80g of modified graphene in 400mL ethanol solution, and add 40g of aluminum tripolyphosphate to it, disperse evenly by ultrasonic waves, then pour it into a reaction vessel, and add 97g of azobisisobutyronitrile to it, and Nitrogen was passed...

Embodiment 3

[0039] A kind of preparation technology based on the anticorrosion coating of graphene modification, specifically as follows:

[0040] In the first step, add 12 g of ethyl orthosilicate to 50 g of ethanol, stir at room temperature for 20-30 minutes, then add 13 g of lauric acid diethanolamide, stir for 30-50 minutes, add water, and stir for 3 hours to obtain a colloidal solution;

[0041] In the second step, add 340g of graphene-based acrylic resin to 400g of ethanol, stir and disperse evenly, add 120g of epoxy resin and the colloid solution prepared in the first step to it, mix evenly, add 30g of gas phase corrosion inhibitor and 22g Defoamer, vigorously stir and mix for 10-15min to obtain component A;

[0042] In the third step, 50 g of polyamide is added to component A, stirred and cured for 10-20 minutes to obtain an anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com