Flexible composite phase change material and preparation method thereof

A technology of composite phase change materials and phase change core materials, which is applied in the field of flexible composite phase change materials and its preparation, can solve the problems of phase change thermal control components such as difficulty in installation, lack of flexibility, and difficulty in installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of flexible composite phase change material, comprises the following steps:

[0032] Provide chitosan acetate solution;

[0033] Provide polyvinyl alcohol aqueous solution;

[0034] mixing carbon nanotubes with water to obtain a suspension of carbon nanotubes;

[0035] adding the carbon nanotube suspension into the chitosan acetic acid solution to obtain a mixed solution;

[0036] Mixing the mixed solution with an aqueous solution of polyvinyl alcohol to obtain a precursor solution;

[0037] Freeze-drying the precursor solution to obtain a carbon nanotube-based airgel carrier;

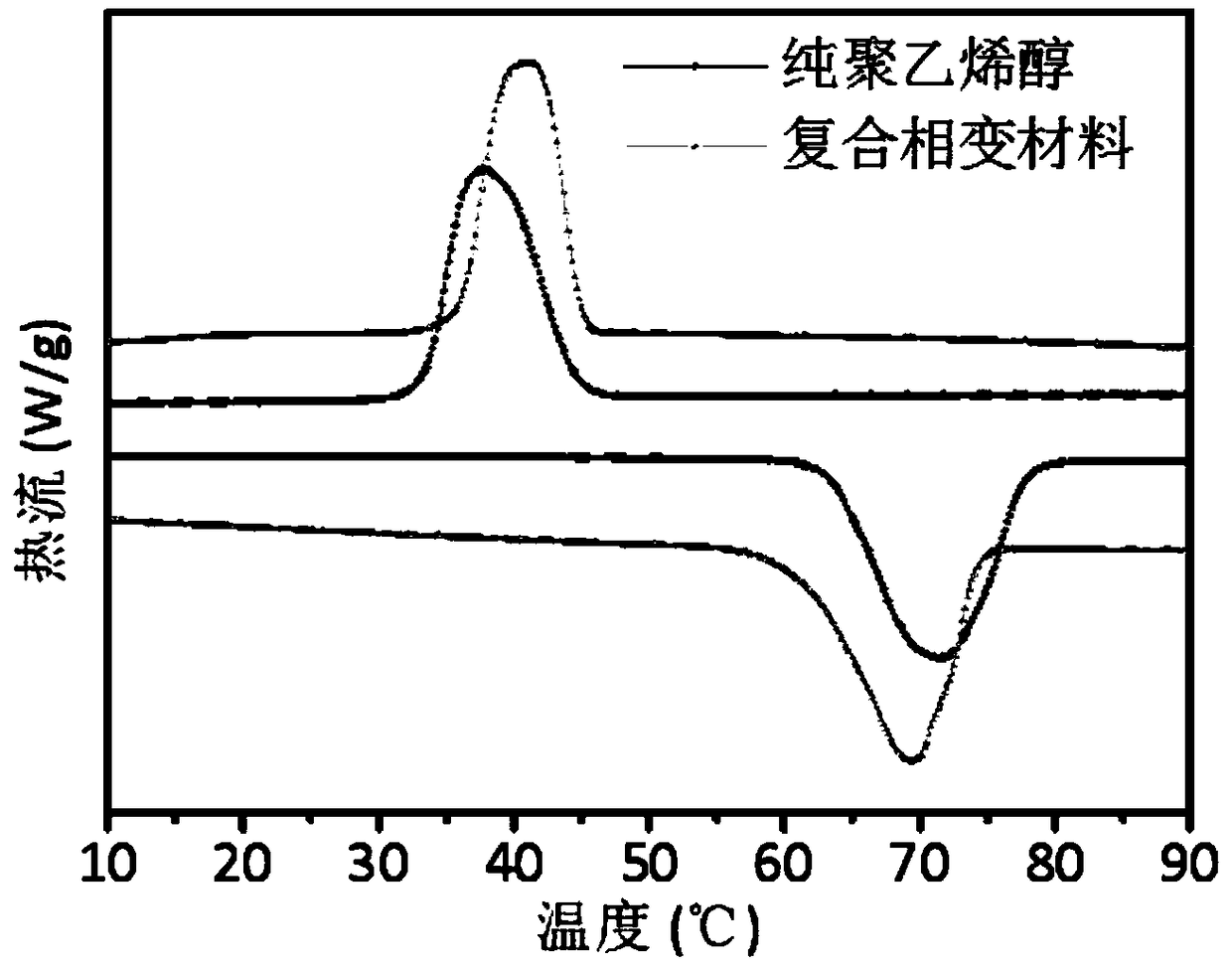

[0038] The carbon nanotube-based airgel carrier is impregnated with a phase-change core material solution to obtain a flexible composite phase-change material, and the phase-change core material solution is polyethylene glycol solution, stearyl alcohol solution or octadecylamine solution.

[0039] The invention provides chitosan acetic acid...

Embodiment 1

[0056] (1) Chitosan is put into molar concentration and is 5mol / L acetic acid solution, carries out ultrasonic stirring treatment, stirs 60min, and stirring speed is 600r / min, obtains the chitosan solution that uniform mass fraction is 1%;

[0057] (2) Add 20 mL of the 5 mg / mL carbon nanotube suspension of ultrasonic 60 min to the above-mentioned chitosan solution 100 mL, and ultrasonically stir for 60 min to obtain a mixed solution for subsequent use;

[0058] (3) 10 mL of the prepared polyvinyl alcohol aqueous solution with a mass fraction of 15% was added to the above mixed solution and ultrasonically pulverized to prepare a precursor solution;

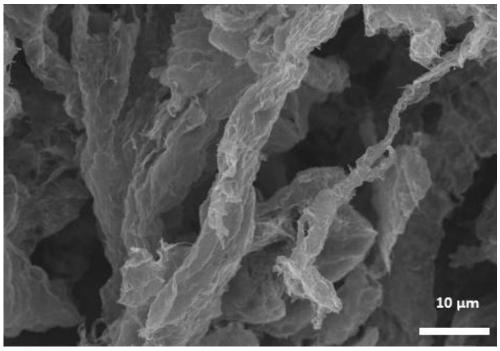

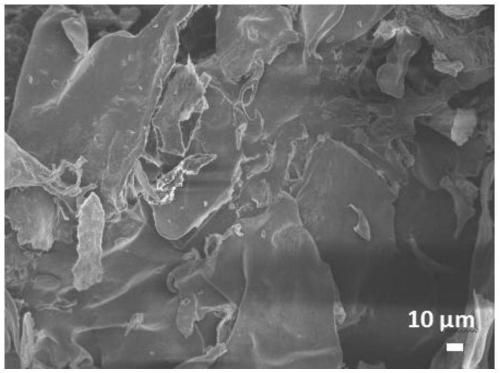

[0059] (4) Put the precursor solution into liquid nitrogen to freeze, the freezing temperature is -196°C, the freezing time is 2h, and the freeze-drying pressure is 36mT; after freezing completely, put it into a freeze dryer to dry to obtain carbon nanotubes with a loose and porous structure based airgel carrier;

[0060] (5) The ...

Embodiment 2

[0066] Same as Example 1, except that the concentration of carbon nanotubes was changed to 10 mg / mL.

[0067] (1) Chitosan is put into molar concentration and is 10mol / L acetic acid solution, carry out ultrasonic stirring process, stir 60min, stirring speed is 600r / min, obtains the chitosan solution that uniform mass fraction is 1%;

[0068] (2) Add 20 mL of the 10 mg / mL carbon nanotube suspension of ultrasonic 60 min into the above-mentioned chitosan solution 100 mL, and ultrasonically stir for 60 min to obtain a mixed solution for subsequent use;

[0069] (3) 10 mL of the prepared polyvinyl alcohol aqueous solution with a mass fraction of 15% was added to the above mixed solution and ultrasonically pulverized to prepare a precursor solution;

[0070] (4) Put the precursor solution into liquid nitrogen to freeze, the freezing temperature is -196°C, the freezing time is 2h, and the freeze-drying pressure is 36mT; after freezing completely, put it into a freeze dryer to dry to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com