Oleophobic modification method of polybutadiene membrane

A polybutadiene modification technology, which is applied in the field of organic membrane modification and preparation, can solve the problems of difficult amplification and complicated process, and achieve the effects of stable air flow, short preparation time and good filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, 0.5 g of silicon dioxide powder and 50 ml of cyclohexane were sonicated to obtain a homogeneous solution. Secondly, 0.5ml of perfluorooctyltrimethoxysilane (PFTMS) was added during the stirring process, and the stirring continued for 10 hours (600 rpm). After the stirring was completed, it was centrifuged at 10000 rpm for 10 minutes. The silicon dioxide particles were dried at 60° C. for 5 hours to obtain hydrophobic and oil-repellent nano silicon dioxide particles.

[0023] Add 2 g of the obtained fluorinated silica nanoparticles to 100 mL of ethanol and stir to obtain a suspension, and filter the suspension of fluorinated silica nanoparticles under a pressure of 0.1 Mpa to adsorb the nanoparticles on the polybutadiene fiber on the surface. Then, the modified film was rinsed repeatedly with ethanol, and finally the polybutadiene film was dried in an oven at 80° C. for 5 hours.

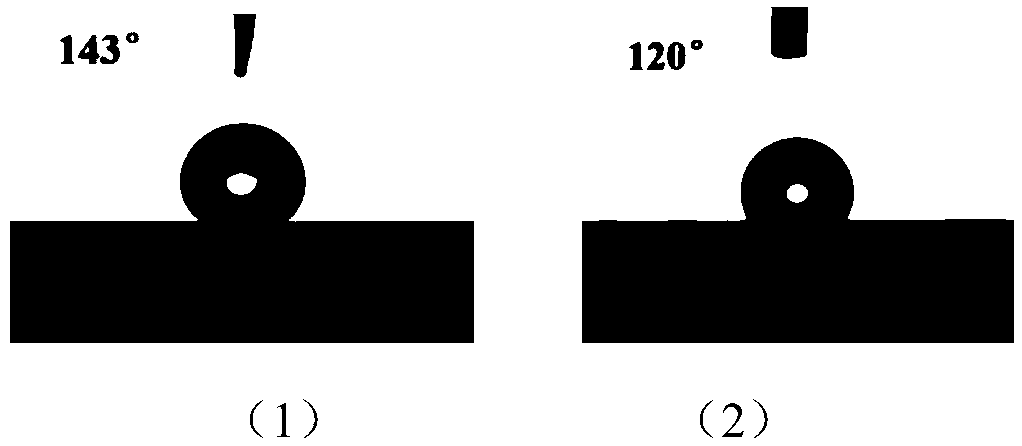

[0024] like figure 1 As shown, the water and cetane oil contact angles of the mod...

Embodiment 2

[0027] First, 1 g of silicon dioxide powder and 50 ml of cyclohexane were sonicated to obtain a homogeneous solution. Secondly, 1ml of perfluorooctyltrichlorosilane was added during the stirring process, and the stirring continued for 12 hours (400 rpm). After the stirring was completed, centrifugation was carried out at 10,000 rpm for 20 minutes. drying at 80°C for 5 hours to obtain hydrophobic and oleophobic nano silicon dioxide particles.

[0028] Add 4 g of the obtained fluorinated silica nanoparticles to 100 mL of ethanol and stir to obtain a suspension, and filter the suspension of fluorinated silica nanoparticles under a pressure of 0.2 Mpa to adsorb the nanoparticles on the polybutadiene fibers on the surface. Then, the modified film was rinsed repeatedly with ethanol, and finally the polybutadiene film was dried in an oven at 100° C. for 5 hours.

[0029] The water contact angle of the modified PTFE membrane is 142°, and the contact angle of cetane oil is 121°.

Embodiment 3

[0031] First, 0.5 g of silicon dioxide powder and 40 ml of cyclohexane were sonicated to obtain a homogeneous solution. Secondly, 0.5ml of perfluorodecyl acrylate was added during the stirring process, and the stirring continued for 16h (600 rpm). drying at 60°C for 10 hours to obtain hydrophobic and oleophobic nano silicon dioxide particles.

[0032] Add 3 g of the obtained fluorinated silica nanoparticles to 100 mL of ethanol and stir to obtain a suspension, and filter the suspension of fluorinated silica nanoparticles under a pressure of 0.1 Mpa to adsorb the nanoparticles on the polybutadiene fibers on the surface. Then the modified film was washed repeatedly with ethanol, and finally the polybutadiene film was dried in an oven at 80°C for 10 hours.

[0033] The water contact angle of the modified PTFE membrane is 140°, and the contact angle of cetane oil is 123°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com